الوصف

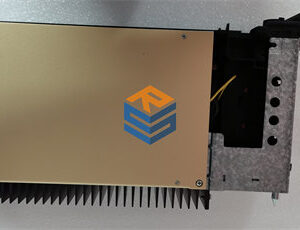

Product Name:

REOTRON 567LH-DP24 DCS PLC Module

Product Description:

The REOTRON 567LH-DP24 DCS PLC Module is a high-performance Distributed Control System (DCS) PLC module specifically designed for industrial process control and automation applications. As part of the REOTRON family of control systems, the 567LH-DP24 module is tailored to meet the requirements of complex, mission-critical operations that require reliable and scalable control solutions. This module is engineered to handle demanding environments such as power generation, chemical processing, water treatment, and manufacturing.

With features like advanced diagnostics, flexible I/O capabilities, redundancy, and real-time communication protocols, the 567LH-DP24 is a robust and reliable choice for controlling and monitoring field devices and processes in various industrial sectors.

Product Parameters:

- Model Number: 567LH-DP24

- Manufacturer: REOTRON

- Type: DCS PLC Module

- System Compatibility: Compatible with REOTRON Distributed Control System architecture.

- Form Factor: Rack-mounted module (typically integrated in control cabinets)

- Power Supply: 24V DC (with dedicated redundant power input option)

- Temperature Range: -20°C to +60°C (-4°F to 140°F) for typical industrial applications

- Humidity Range: 5% to 95% non-condensing

- Weight: Approx. 2.0 kg (varies with configuration)

- Mounting Type: Rack-mounted (Standard REOTRON system integration)

- Redundancy Options: Dual communication ports and optional redundant power supplies

- Input/Output Type: Configurable analog and digital I/O

- Communication Protocols Supported:

- Modbus RTU/TCP

- Profibus DP

- Ethernet/IP

- DeviceNet

- OPC (for data exchange)

Product Specifications:

-

I/O Capabilities:

- Analog I/O:

- Analog Inputs: Configurable for 4-20mA, 0-10V, and other signals.

- Analog Outputs: Used for controlling process actuators, valves, or motors with precision.

- Digital I/O:

- Digital Inputs: Accepts signals from discrete sensors (e.g., switches, proximity sensors).

- Digital Outputs: Used for controlling devices such as relays, solenoids, and actuators.

- Flexible I/O Configuration: I/O points can be configured for either analog or digital signals to meet specific application needs.

- Analog I/O:

-

Control and Communication:

- The 567LH-DP24 integrates with REOTRON’s DCS system, ensuring seamless communication across distributed control networks.

- Multiple communication protocols such as Modbus, Profibus, and Ethernet/IP support reliable data exchange between the controller and field devices.

- Supports OPC for easy integration with other enterprise and SCADA systems.

-

Redundancy and Fault Tolerance:

- Features dual communication ports for redundant operation, ensuring continuous communication and data integrity even if one port fails.

- Redundant power supplies are available for systems requiring high availability, preventing system downtime during power disruptions.

-

Real-time Control:

- The 567LH-DP24 provides real-time control capabilities, allowing quick processing of field data and the fast execution of control commands for time-critical processes such as motor control, valve adjustments, and sensor readings.

- The module supports high-speed I/O processing, enabling responsive and reliable control of automated systems.

-

Diagnostics and Monitoring:

- Integrated diagnostics provide continuous monitoring of system performance, allowing for proactive maintenance and troubleshooting.

- Diagnostic features include status indicators, error logs, and self-diagnostics that can alert operators to potential system issues before they escalate.

- Real-time monitoring ensures operators have access to key performance metrics to manage process stability.

-

Environmental and Durability Features:

- Designed for use in industrial environments, the 567LH-DP24 is built to withstand vibrations, electrical noise, and electromagnetic interference (EMI).

- The operating temperature range is -20°C to +60°C (-4°F to 140°F), making it suitable for a wide variety of industrial applications, including outdoor environments or harsh industrial conditions.

-

System Integration:

- Seamlessly integrates with other REOTRON DCS components such as control panels, I/O modules, and supervisory systems.

- Offers scalability for both small and large systems, from simple control applications to large, complex industrial operations.

- Designed to simplify system configuration, allowing operators to easily configure, monitor, and troubleshoot the system through an intuitive interface.

-

Safety Features:

- Adheres to international safety standards to ensure personnel and equipment are protected from hazards.

- Supports safe interlocking, emergency shutdown, and safety loops for critical applications.

Key Features:

- Modular I/O Configuration: Supports both analog and digital I/O, allowing for flexible configuration tailored to process requirements.

- Multiple Communication Protocols: Supports a wide range of industrial communication standards, including Modbus, Profibus, Ethernet/IP, and DeviceNet.

- Redundancy: Dual communication ports and optional redundant power supply for increased system availability.

- Real-time Control: Quick and reliable processing of input signals, ideal for time-sensitive industrial processes.

- Diagnostic and Monitoring Tools: Advanced diagnostics and real-time system health monitoring for early issue detection and reduced downtime.

- Environmental Durability: Operates efficiently in harsh industrial conditions, with a wide operating temperature range.

- Safety Features: Compliance with industry-standard safety regulations, including interlocks and emergency shutdown protocols.

Applications:

The REOTRON 567LH-DP24 DCS PLC Module is suitable for a wide range of industrial control and automation applications:

-

Power Generation:

- Used in boiler control, turbine monitoring, and generator synchronization in power plants.

- Real-time monitoring and control of temperature, pressure, and flow rates ensure operational efficiency and safety.

-

Chemical Processing:

- Ideal for controlling chemical reactors, mixing systems, and dosing equipment.

- Enables precise control of temperature, pressure, and chemical composition for optimal product quality and safety.

-

Water Treatment:

- Used for controlling pumps, valves, filters, and chemical dosing in water treatment facilities.

- Provides real-time data on water quality and resource optimization, ensuring compliance with environmental standards.

-

Oil and Gas:

- Critical for pipeline monitoring, pressure control, and emergency shutdown systems in upstream and downstream oil and gas operations.

- Ensures the continuous, safe operation of equipment such as compressors, flow meters, and valve stations.

-

Manufacturing:

- Controls automated production lines, including robotic arms, conveyor systems, and assembly stations.

- Facilitates real-time monitoring, quality control, and process tracking, improving operational efficiency and minimizing downtime.

Conclusion:

The REOTRON 567LH-DP24 DCS PLC Module offers a highly reliable and flexible solution for industrial process control and automation. With features like real-time control, redundancy, and advanced diagnostics, it is well-suited for demanding applications across industries such as power generation, chemical processing, water treatment, and manufacturing. Its modular design, wide communication protocol support, and robust environmental performance make it a versatile component for building scalable, reliable, and efficient control systems in industrial environments.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922