الوصف

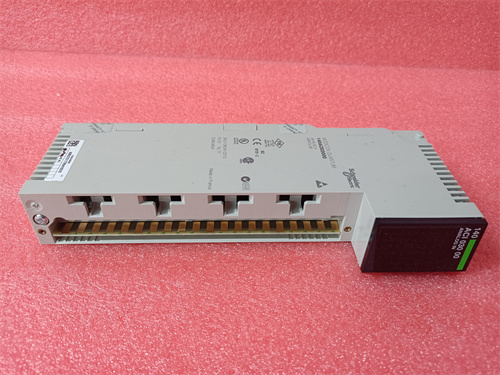

Alright, let’s break down the SCHNEIDER 140CPU43412. This part number immediately tells me we’re looking at a core component of a Programmable Logic Controller (PLC) system, specifically a CPU module from Schneider Electric’s Modicon Quantum automation platform. This isn’t just a simple chip; it’s the brain of an industrial control system, responsible for executing logic, managing I/O, and ensuring the precise operation of machinery and processes.

SEO Optimized Headings:

- SCHNEIDER 140CPU43412: High-Performance Modicon Quantum PLC Processor.

- Modicon Quantum 140CPU43412: Central Processing Unit for Industrial Automation.

- SCHNEIDER 140CPU43412 CPU Module: Reliable Control for Complex Machinery.

- 140CPU43412: Key Component of Schneider Electric’s Automation Platform.

- SCHNEIDER 140CPU43412: Enhanced Processing Power for Industrial Applications.

- PLC CPU 140CPU43412: Efficient and Stable Industrial Control.

- SCHNEIDER 140CPU43412: Integrated Communication for Seamless Operations.

- Modicon Quantum Processor 140CPU43412: Designed for Demanding Industrial Environments.

- SCHNEIDER 140CPU43412: Flexible I/O Management for Diverse Automation Needs.

- 140CPU43412: Legacy Control Solution with Proven Reliability.

Product Summary (Product Detail Card & Search Page Description):

The SCHNEIDER 140CPU43412 is a CPU module for the Schneider Electric Modicon Quantum series of Programmable Logic Controllers (PLCs). Featuring an 80486 processor with a 66 MHz clock frequency and 896 kB of internal RAM, it delivers robust processing power for industrial automation tasks. This module supports versatile I/O configurations and includes Modbus Plus and Modbus RS232 ports for extensive connectivity, making it ideal for controlling a wide range of industrial applications.

Product Type: CPU Module (Central Processing Unit) Series: Modicon Quantum Automation Platform Processor: 80486 (66 MHz) Memory: 896 kB Internal RAM Communication: 1 x Modbus Plus, 2 x Modbus RS232

Detailed Product Description

When you’re dealing with the intricate choreography of an automated factory floor, every movement, every measurement, and every decision needs to be executed with unwavering precision. That’s where a component like the SCHNEIDER 140CPU43412 comes into play. Quite simply, it’s the brains behind the brawn, translating complex programming into real-world industrial actions.

As an automation specialist, I recognize the 140CPU43412 as a central processing unit for the Modicon Quantum platform. While the 80486 processor at its core, running at 66 MHz, might seem modest by today’s PC standards, it’s perfectly tuned for the deterministic, real-time control demanded by industrial PLCs. This processor is engineered for reliability and efficient execution of ladder logic, function blocks, and other control programs. It’s not about raw speed for graphics or web Browse; it’s about predictable, repeatable performance for controlling machines that build cars, bottle beverages, or manage chemical processes. The 896 kB of internal RAM provides ample space for program storage and data handling, ensuring smooth operation even with complex applications.

From the perspective of a plant manager or maintenance engineer, the longevity and robustness of the Modicon Quantum platform, anchored by CPUs like the 140CPU43412, are significant advantages. These units are built to withstand the harsh realities of industrial environments – temperature fluctuations, electrical noise, and constant operation. They’re designed for minimal downtime, which directly translates to sustained production and reduced operational costs. The inclusion of Modbus Plus and Modbus RS232 communication ports means seamless integration into existing industrial networks and easy connectivity for programming and diagnostics. This widespread compatibility simplifies upgrades and troubleshooting, making it a reliable workhorse for critical industrial applications.

Key Features and Core Benefits:

Robust Processing Power: At its core, the 140CPU43412 features an 80486 processor operating at a 66 MHz clock frequency. This provides the stable and dedicated computational power necessary for executing complex PLC logic, handling real-time control tasks, and managing I/O operations with precision. While not a modern PC processor, it’s highly optimized for the demanding, deterministic nature of industrial automation.

Ample Internal Memory: Equipped with 896 kB of internal RAM, this CPU offers significant memory capacity for storing program logic, data tables, and configuration parameters. This generous memory ensures that even sophisticated control applications can run smoothly and efficiently, supporting various industrial processes.

Versatile Communication Interfaces: The module includes one Modbus Plus port and two Modbus RS232 ports. Modbus Plus is a high-speed peer-to-peer network for distributed control, while Modbus RS232 offers standard serial communication. This diverse connectivity allows for seamless integration with other PLCs, HMIs, drives, and field devices, enabling a truly connected automation system.

Flexible I/O Capabilities: The processor supports a wide range of I/O configurations, including up to 64 inputs and 64 outputs locally or remotely, and 30 inputs and 32 outputs in distributed configurations. It can also handle up to 500 distributed I/O words per network, providing significant flexibility to connect to various sensors, actuators, and I/O modules to meet diverse application requirements.

Industrial-Grade Reliability: Designed for demanding industrial environments, the 140CPU43412 is built with robust components and features like a 250 ms watchdog timer to monitor system integrity. It operates reliably across a temperature range of 0°C to 60°C and is resistant to electrostatic discharge and electromagnetic fields, ensuring consistent performance and minimizing downtime.

Technical Specifications:

Applications:

The SCHNEIDER 140CPU43412 is a workhorse in various industrial settings where robust and reliable control is paramount. Think about any manufacturing plant where precise timing and sequence are critical – from ensuring that bottles are filled correctly on a production line to coordinating complex robotic movements in an assembly plant.

This CPU module is primarily used in:

- Manufacturing and Assembly Lines: Controlling discrete processes, conveyor systems, and robotic cells for automated production.

- Packaging Machinery: Managing the precise timing and movement of various packaging steps, including filling, sealing, and labeling.

- Material Handling Systems: Automating warehouse logistics, sortation systems, and automated storage and retrieval systems (AS/RS).

- Water and Wastewater Treatment: Controlling pumps, valves, and filtration processes to manage water flow and quality.

- Food and Beverage Production: Automating mixing, cooking, filling, and packaging processes while ensuring hygiene and consistency.

- Automotive Industry: Used in various stages of vehicle manufacturing, from body shop automation to final assembly.

- Pharmaceutical Production: Ensuring precise control over batch processes, mixing, and packaging in a regulated environment.

Related Products You Might Be Interested In:

To build or maintain a complete automation system around the SCHNEIDER 140CPU43412, you’ll often need other components that complement its functionality. Here are some related products that could be part of a Modicon Quantum system or offer relevant alternatives:

- Schneider Electric Modicon Quantum I/O Modules: These are the various digital and analog input/output modules (e.g., 140DDIxxxx, 140DRAxxxx) that connect to the CPU via the backplane, allowing it to interface with field devices.

- Schneider Electric Modicon Quantum Communication Modules: Additional communication cards (e.g., Ethernet modules like 140NOE77111, or other specialized network cards) to expand connectivity options.

- Schneider Electric Modicon Quantum Power Supplies: Modules designed to provide stable power to the Quantum rack and its installed modules.

- Schneider Electric Modicon Quantum Racks/Chassis: The physical enclosures (e.g., 140CRPxxxx) into which the CPU, power supply, and I/O modules are inserted.

- Schneider Electric Unity Pro / Control Expert Software: The current engineering software used for programming, configuring, and maintaining Modicon Quantum (and other Schneider PLCs). For older systems, Concept and ProWORX32 were the primary programming tools.

- Modicon Quantum Batteries: Lithium batteries are required for maintaining RAM contents when the CPU is powered off (e.g., 140CPU43412 has a 10-year battery life).

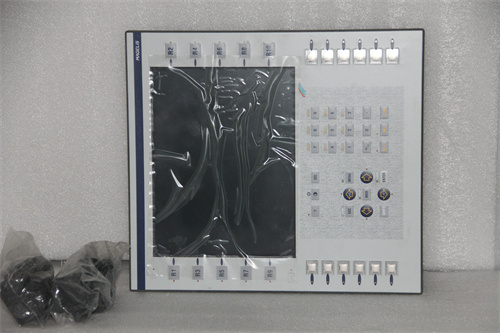

- Human Machine Interface (HMI) Panels: Such as Schneider Electric Magelis HMI displays, which provide an operator interface for monitoring and controlling the PLC-driven process.

- Variable Speed Drives (VSDs): Like Schneider Electric Altivar drives, often controlled by the PLC for precise motor speed and torque regulation.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922