الوصف

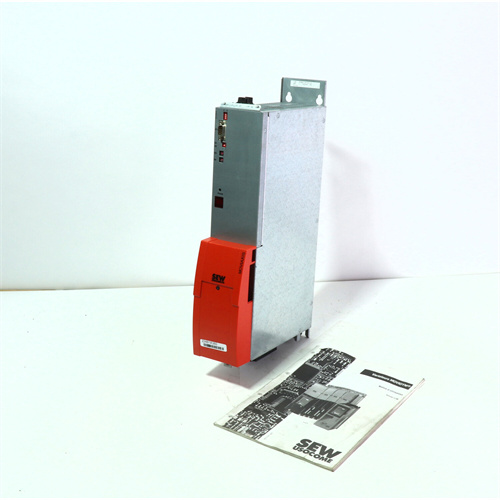

Product Name

SEW+DFS56L/TF/RH1M/KK

Product Description

The SEW+DFS56L/TF/RH1M/KK is a highly efficient drive system designed for advanced automation applications. This product combines the precision of SEW’s engineering with sophisticated control capabilities, making it a reliable choice for various industries. The SEW+DFS56L/TF/RH1M/KK features a compact design, easy installation, and integration capabilities, ensuring a seamless operational flow. With its robust features, users can expect excellent performance and longevity.

Product Parameters

- Model: SEW+DFS56L/TF/RH1M/KK

- Rated Output Power: 5.5 kW

- Input Voltage: 400V

- Control Type: Vector control

- Protection Rating: IP65

- Communication Protocols: CANopen, Profibus, Ethernet/IP

- Operating Temperature: -10 to +40°C

Advantages and Features

The SEW+DFS56L/TF/RH1M/KK offers several remarkable advantages:

- High Efficiency: Increases energy savings and reduces operational costs.

- Versatile Applications: Suitable for a wide range of machinery, enhancing adaptability.

- User-Friendly Interface: Simplifies programming and monitoring through its intuitive control system.

- Durability: Built to withstand harsh environments, ensuring a long operational life.

- Flexible Integration: Easily integrates with existing systems thanks to various communication protocols.

Application Fields and Case Studies

The SEW+DFS56L/TF/RH1M/KK is applied across various sectors including:

- Manufacturing: Used in conveyor systems for automated assembly lines.

- Food and Beverage: Drives packaging and bottling machinery.

- Textile Production: Facilitates the control of weaving and knitting machines.

- Material Handling: Employed in warehouse automation for sorting and transportation.

A notable case study involves the implementation of the SEW+DFS56L/TF/RH1M/KK in a large-scale food processing plant, where it was integral in automating the packaging line, reducing manual labor and significantly increasing productivity.

Competitor Comparison

When comparing the SEW+DFS56L/TF/RH1M/KK with competitors such as the Allen-Bradley PowerFlex series or Siemens Sinamics drives, the SEW model stands out for its superior energy efficiency and advanced integration capabilities. While other brands maintain robust performance, the SEW+DFS56L/TF/RH1M/KK often provides a more user-friendly experience with lower total cost of ownership due to its energy-saving features.

SEW+DFS56L/TF/RH1M/KK

SIEMENS 6ES7414-2XG04-0AB0

A-B 1747-L553

Kollmorgen BJRL-20012-110001

RELIANCE ELECTRIC WR-D4004

EPRO PR6423/003-030

PROSOFT MV156E-MCMR

FIFE CDP-01-MM

Emerson FX-208

CTI 2500-C200

SIEMENS 6AV3688-3CD13-0AX0

A-B 1756-L71

SCHNEIDER 140CPU65150

ABB CI867K01

A-B 1747-L553

EMERSON A6500-RC

ABB 64711245C

A-B 1747-L551

Aerotech BAI20-320

TRICONEX 3503E

BENTLY 330851-02-000-070-10-00-05

PTM PSMU-350-3

ABB 3AFE61320946P0001

Kollmorgen CB06560

Siemens 6SN1145-1AA01-0AA2

Siemens 6SN1123-1AA00-0EA2

A-B 1336-WB110

SIEMENS 6SE7027-2TD84-1HF5

GE DS2020FECNRX010A

GE 8851-LC-MT

ELAU MC-4/11/10/400

ABB 3HAC12928-1 REV8

ABB 70PR05B-ES

PROSOFT MVI56E-MCM

TRICONEX 3201

SIEMENS 6DL4340-0BA00

REXROTH DKC11.3-040-7-FW FWA-ECODR3-SMT-02VRS-MS

YASKAWA CACR-SR20BE12G-E

REXROTH MKD071B-061-KG1-KN

ABB 07KR264

A-B 1756-RM

GE IC698CMX016

ABB CI858

PROSOFT PTQ-PDPS

GE DS200IIBDG1A

KEYTHLEY 2230G-30-1

YASKAWA SGMGH-44A2A-YR14

ABB ICMK14N1

FOXBORO FBM224

A-B 1756-RM

BENTLY 3500/33

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922