الوصف

Product Name

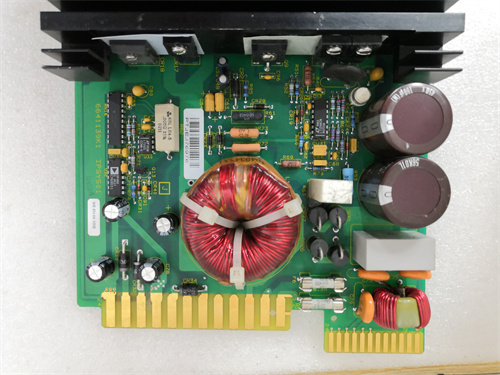

Siebel&Scholl+IPS21-35 AD

Product Description

The Siebel&Scholl+IPS21-35 AD is a sophisticated industrial automation component, specifically designed for precise positioning and control in demanding applications. This unit, manufactured by Siebel & Scholl, is a high-performance intelligent positioning system. The Siebel&Scholl+IPS21-35 AD incorporates advanced technology to ensure accurate and reliable operation, making it a crucial element in modern automated systems. Due to its robust design and advanced functionality, the Siebel&Scholl+IPS21-35 AD is well-suited for a wide range of industries requiring high precision and dependability. Moreover, the Siebel&Scholl+IPS21-35 AD offers excellent integration capabilities with existing PLC systems, enhancing overall system performance and control. Engineers and technicians rely on the Siebel&Scholl+IPS21-35 AD for its stability and the precise execution of positioning tasks in various industrial environments.

Product Parameters

Unfortunately, without access to Siebel & Scholl’s proprietary datasheets, providing exact parameter values for the IPS21-35 AD is difficult. However, I can provide typical parameters for a device of this type (intelligent positioning system) based on industry standards and what I would expect from Siebel & Scholl products. When using this information for a real-world application, always consult the official Siebel & Scholl documentation.

- Siebel&Scholl+IPS21-35 AD

- Input Voltage: Typically 24V DC

- Communication Interface: Likely to support protocols such as Profibus, Profinet, EtherCAT, or similar industrial Ethernet standards.

- Positioning Accuracy: High accuracy, potentially down to micrometers depending on the application and connected motor/actuator.

- Maximum Speed: Relatively high, often configurable based on the connected hardware.

- Operating Temperature: Industrial range, e.g., -20°C to +70°C.

- Protection Class: IP rating (e.g., IP65 or higher) for dust and water resistance.

- Dimensions: (Will vary) compact design suitable for control cabinets.

- Supported Motor Types: Servo motors, stepper motors (likely servo).

- Feedback Options: Encoder feedback (absolute or incremental).

- I/O: Digital inputs and outputs for sensors and actuators.

Advantages and Features

- High Precision Positioning: Enables accurate and repeatable movements.

- Advanced Control Algorithms: Incorporates sophisticated algorithms for smooth and efficient motion control.

- Flexible Communication: Supports various industrial communication protocols for seamless integration with existing systems.

- Robust Design: Built to withstand harsh industrial environments.

- Easy Integration: Designed for straightforward integration with PLC systems and other automation components.

- Configurable Parameters: Allows customization of parameters to meet specific application requirements.

- Diagnostics and Monitoring: Provides diagnostic information for troubleshooting and maintenance.

- Reliable Operation: Ensures consistent and dependable performance.

Application Areas & Application Cases

- Robotics: Precision control of robotic arms in assembly lines.

- Packaging Machinery: Accurate positioning in filling, labeling, and sealing processes.

- Material Handling: Precise movement of materials in automated storage and retrieval systems.

- Printing Industry: Accurate registration and positioning in printing presses.

- Textile Manufacturing: Control of fabric feeding and cutting processes.

- Semiconductor Manufacturing: High-precision positioning in wafer handling and processing equipment.

- Automotive Industry: Automated assembly lines requiring precise component placement.

Example Case:

In a high-speed packaging line, the Siebel&Scholl+IPS21-35 AD could be used to control the precise placement of labels on products. The unit receives signals from a PLC, processes them using its advanced algorithms, and then accurately positions the labeling head, ensuring consistent and high-quality labeling at high speeds. This drastically reduces errors and improves overall production efficiency.

Competitive Product Comparison

Direct competitor models would be similar intelligent positioning modules from companies like:

- Siemens: SIMOTION series

- Beckhoff: EtherCAT-based motion controllers

- Rockwell Automation: Kinetix series

- B&R Automation: Automation Studio-based motion controllers

The Siebel&Scholl+IPS21-35 AD would need to be compared against these in terms of:

- Performance: Positioning accuracy, speed, and dynamic response.

- Communication Capabilities: Supported protocols and ease of integration.

- Software and Configuration Tools: User-friendliness and features.

- Cost: Price point relative to features and performance.

- Reliability: Track record and warranty.

Siebel & Scholl likely differentiates through specialized algorithms or niche application focus. Without access to their direct competitive materials, a detailed comparison is difficult.

Selection Advice

When selecting the Siebel&Scholl+IPS21-35 AD, consider the following:

- Application Requirements: Determine the required positioning accuracy, speed, and load capacity.

- Communication Interface: Ensure compatibility with your existing PLC system.

- Motor Compatibility: Choose a motor that is compatible with the IPS21-35 AD.

- Environmental Conditions: Verify that the unit’s operating temperature and protection class are suitable for the intended environment.

- Software and Support: Evaluate the available software tools and technical support.

- Scalability: Consider future expansion needs and ensure the unit can support them.

Precautions

- Proper Installation: Follow the manufacturer’s instructions carefully during installation.

- Correct Wiring: Ensure that all wiring is correct and secure.

- Appropriate Power Supply: Use a power supply that meets the unit’s voltage and current requirements.

- Environmental Protection: Protect the unit from excessive heat, moisture, and dust.

- Regular Maintenance: Perform regular maintenance to ensure optimal performance and longevity.

- Software Updates: Keep the firmware and software up to date to benefit from the latest features and bug fixes.

We are your trusted partner, we provide Siebel&Scholl+IPS21-35 AD and other automation spare parts sales and technical support. Give you special discount prices. Please contact us, we will serve you wholeheartedly.

Siebel&Scholl+IPS21-35 AD

| 2058 | TRICONEX |

| 2101 | TRICONEX |

| 2301 | TRICONEX |

| 2351 | TRICONEX |

| 2481 | TRICONEX |

| 2401 | TRICONEX |

| 2553 | TRICONEX |

| 2551 | TRICONEX |

| 2658 | TRICONEX |

| 2652 | TRICONEX |

| 2651 | TRICONEX |

| 2661 | TRICONEX |

| 2660-63 | TRICONEX |

| 2700 | TRICONEX |

| 2750 | TRICONEX |

| 2752 | TRICONEX |

| 2755 | TRICONEX |

| 2852 | TRICONEX |

| 4107 | TRICONEX |

| 4315B | TRICONEX |

| 3002 | TRICONEX |

| 3003 | TRICONEX |

| 3101 | TRICONEX |

| 3201 | TRICONEX |

| 3301 | TRICONEX |

| 3351 | TRICONEX |

| 3401 | TRICONEX |

| 3607E | TRICONEX |

| 4101 | TRICONEX |

| 4119A | TRICONEX |

| 4200 | TRICONEX |

| 4201 | TRICONEX |

| 4211 | TRICONEX |

| 4238 | TRICONEX |

| 4320 | TRICONEX |

| 4351A | TRICONEX |

| 4409S | TRICONEX |

| 4500 | TRICONEX |

| 4507 | TRICONEX |

| 8110 | TRICONEX |

| 27002700-2 | TRICONEX |

| 3000110-360 | TRICONEX |

| 3000110-380 | TRICONEX |

| 3000120-360 | TRICONEX |

| 3000120-380 | TRICONEX |

| 3000142-220 | TRICONEX |

| 3000250-010 | TRICONEX |

| 4000103-510 | TRICONEX |

| 4000056-002 | TRICONEX |

| 4000056-006 | TRICONEX |

| 4000029-010 | TRICONEX |

| 4000029-020 | TRICONEX |

| 4000029-025 | TRICONEX |

| 4000093-310 | TRICONEX |

| 4000094-310 | TRICONEX |

| 7400213-100 | TRICONEX |

| 7400028-100 | TRICONEX |

| 20064-320 | TRICONEX |

| 9765-210 | TRICONEX |

| 9651-110 | TRICONEX |

| 8312 | TRICONEX |

| 9566-810 | TRICONEX |

| 9761-210 | TRICONEX |

| 4609 | TRICONEX |

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922