الوصف

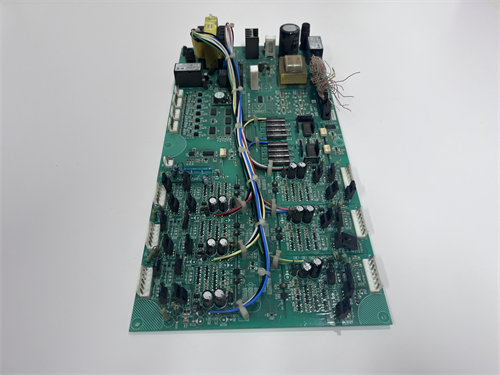

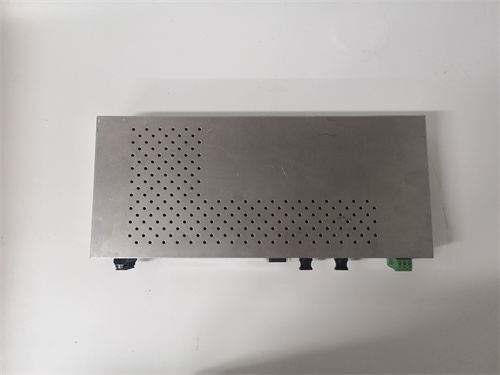

The TOSHIBA TBU31A DCS/PLC Module is part of Toshiba’s family of Distributed Control System (DCS) and Programmable Logic Controller (PLC) modules designed for industrial automation and control. Below is the detailed information regarding its product name, description, parameters, and specifications.

Product Name:

TOSHIBA TBU31A DCS/PLC Module

Product Description:

The TOSHIBA TBU31A is an advanced DCS/PLC module designed to provide reliable control and communication in industrial automation systems. It is suitable for use in large-scale control applications, where continuous monitoring and precise control of equipment, machinery, or processes are required.

This module is engineered to handle complex process control, making it ideal for industries like oil & gas, chemical manufacturing, power generation, and automated manufacturing. The TBU31A is well-suited for integrating with various industrial systems, providing a scalable and flexible platform for managing real-time operations, ensuring the safety of critical processes, and offering high availability.

The TBU31A also supports several communication protocols and is built with redundancy features, ensuring that control systems remain operational even in case of hardware failure or network disruption. The module supports advanced diagnostic capabilities, making troubleshooting and predictive maintenance easier.

Key Features:

-

High Flexibility:

- Offers extensive I/O options, supporting digital, analog, and specialized I/O for a variety of applications.

-

Real-Time Data Processing:

- Capable of fast, real-time control and data handling, crucial for dynamic process adjustments.

-

Multiple Communication Protocols:

- Supports Ethernet/IP, Modbus TCP, Profibus, HART, and other industrial protocols to ensure seamless integration with different control systems.

-

Redundant Design:

- Built-in redundancy for power and communication to guarantee high system availability and minimize downtime.

-

Modular Configuration:

- Flexible design allows easy addition of modules or expansion of control systems.

-

Diagnostics and Monitoring:

- Advanced diagnostic features that allow for early fault detection, real-time monitoring, and the generation of alerts or logs for predictive maintenance.

-

Safety Compliance:

- Certified for use in safety-critical environments, offering SIL (Safety Integrity Level) features for hazardous industrial applications.

-

User-Friendly Interface:

- Compatible with Toshiba’s system software and programming tools, allowing intuitive configuration and control system management.

Product Parameters and Specifications:

General Specifications:

- Product Name: TOSHIBA TBU31A DCS/PLC Module

- Control System Type: DCS/PLC Communication Module

- Manufacturer: Toshiba Corporation

- Module Type: Programmable Logic Controller (PLC) / Distributed Control System (DCS) Integration

- Functionality: Real-Time Control, Monitoring, Communication, I/O Integration

Electrical Specifications:

-

Input Voltage:

- 24V DC (nominal), input range typically from 20V DC to 30V DC.

-

Power Consumption:

- Typical range from 15W to 40W, depending on the configuration and load.

-

Operating Temperature Range:

- 0°C to 60°C (32°F to 140°F).

- Suitable for industrial environments with moderate temperature fluctuations.

-

Storage Temperature Range:

- -40°C to 85°C (-40°F to 185°F), allowing storage in extreme conditions.

-

Relative Humidity:

- 5% to 95%, non-condensing humidity for optimal performance.

I/O Configuration:

-

Digital I/O:

- Supports a wide variety of digital inputs (e.g., for sensors, limit switches, relays) and digital outputs (e.g., actuators, solenoids, relays).

-

Analog I/O:

- Supports analog inputs (e.g., 4-20mA, 0-10V) for measuring physical parameters like temperature, pressure, flow, etc.

- Supports analog outputs to control actuators, motors, and other variable devices.

-

Specialized I/O:

- Available options for high-speed inputs, encoder inputs, and other specialized interfaces for custom applications.

Communication & Networking:

-

Communication Protocols Supported:

- Ethernet/IP, Modbus TCP, Profibus, HART, DeviceNet, CANopen, and other industrial protocols for seamless integration with various control and monitoring systems.

-

Redundant Communication Paths:

- Dual Ethernet ports (for redundancy) and other redundant communication options for improved system uptime and reliability.

-

Data Transfer Rate:

- Ethernet-based communication supports 100 Mbps (Fast Ethernet) data transfer rates for high-speed communication.

- Serial ports typically support 9600-115200 baud for Modbus RTU or other fieldbus protocols.

-

Fieldbus Interface:

- Optional configurations support various fieldbus interfaces like Profibus-DP and Modbus RTU.

Safety and Compliance:

-

SIL Compliance:

- Meets SIL-2 or SIL-3 (depending on configuration) for safety-critical systems, ensuring reliable operation in safety-related applications.

-

EMC Compliance:

- Designed to comply with Electromagnetic Compatibility (EMC) standards, ensuring that the module is resilient to electromagnetic interference from industrial environments.

-

Hazardous Location Compliance:

- Available configurations with ATEX or IECEx certification for use in explosive atmospheres and hazardous locations.

Software and Programming:

-

Programming Languages:

- Fully compatible with IEC 61131-3 standard, supporting Ladder Logic, Structured Text, Function Block Diagram, and Sequential Function Chart.

-

System Configuration Software:

- Utilizes Toshiba’s proprietary software tools for easy programming, configuration, and system integration. These tools provide graphical interfaces, debugging tools, and monitoring capabilities.

-

Integration with SCADA/HMI:

- Seamlessly integrates with SCADA systems and HMI (Human-Machine Interface) for full supervisory control and data acquisition.

Maintenance and Diagnostics:

-

Real-Time Monitoring:

- Built-in diagnostics with real-time monitoring features for continuous system health checks and troubleshooting.

-

Predictive Maintenance:

- Diagnostic tools allow for predictive maintenance, helping identify potential failures before they cause significant downtime.

-

Error Logging:

- Event logging and alarm history for tracking system performance and resolving issues efficiently.

Expansion and Scalability:

-

Modular System:

- The TBU31A can be easily expanded by adding additional I/O modules, communication modules, or specialized units, allowing for scalable system development.

-

Upgrades:

- Supports software and hardware upgrades to adapt to evolving industrial automation needs.

Applications:

-

Power Generation:

- Used for controlling turbines, generators, and other equipment in power plants.

-

Oil & Gas:

- Controls refineries, offshore rigs, and pipeline monitoring for safety-critical applications.

-

Chemical Manufacturing:

- Provides control and monitoring of chemical reactors, distillation columns, and other processes in chemical plants.

-

Automated Manufacturing:

- Integrates with robotics, assembly lines, and conveyor systems to optimize production efficiency and quality.

-

Water and Wastewater Treatment:

- Monitors and controls pumps, valves, and chemical dosing systems in water treatment facilities.

-

Industrial Machinery:

- Controls a wide range of automated machines, CNC machines, presses, and conveyors in manufacturing environments.

Conclusion:

The TOSHIBA TBU31A DCS/PLC Module is a high-performance, versatile module ideal for industrial automation systems. With its advanced diagnostics, redundant design, and wide communication protocol support, it is an excellent solution for controlling and monitoring critical processes in various industries. Its flexibility, scalability, and safety compliance make it a reliable choice for a wide range of applications, from manufacturing automation to safety-critical environments.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922