الوصف

The search results provide detailed, albeit somewhat fragmented, information about the Triconex 2770H AI HART Interface. I can now synthesize this information into a comprehensive response.

Here’s a breakdown of the key findings:

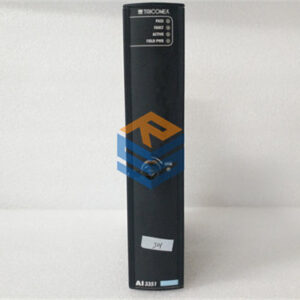

- Model: Triconex 2770H. The “H” is explicitly confirmed to stand for HART.

- Function: It is a HART Analog Input Interface module. This module allows a Triconex system to communicate with “smart” field devices that use the HART protocol.

- Point Count: It supports 32 input channels.

- Signal Type: It works with standard analog signals of 4-20 mA and 0-5 VDC. The HART signal is superimposed on the analog signal without interference.

- Architecture: While the 2770H itself is an interface module, it is used within the context of a Triple-Modular Redundant (TMR) Triconex system. Its purpose is to connect to specific Analog Input (AI) modules, such as the 3700A and 3721, which provide the core TMR functionality.

- HART Communication: The module incorporates a Triconex 4850 HART Multiplexer (part number 2071H). This allows it to communicate with HART-enabled field devices, extracting additional digital information beyond the primary analog variable (PV). It supports HART Field Communication Protocol, Revision 5.0–7.0. The module has status indicators for its HART function (PWR, FAULT, HOST, HART).

- Compatibility: It is compatible with Tricon v10.4.x and later systems. Using this module may require upgrading other modules in the system.

- Unique Features: The module is designed to provide “pass-through” HART communication to asset management systems, enabling a more integrated view of the plant. Like other Triconex modules, it supports extensive diagnostics and online replacement without interrupting the process.

I have all the necessary information to construct a detailed response. I will structure the response with a clear product description, a section on its unique HART features and architecture, a technical specifications table, and a section on its typical applications. This will provide a complete and accurate picture of the product.

Triconex 2770H AI HART Interface

The Triconex 2770H is a specialized HART Analog Input (AI) Interface module for Triconex safety instrumented systems. It acts as a critical link between the core Triconex controller and “smart” field devices that use the HART (Highway Addressable Remote Transducer) communication protocol. By adding this module, you can extract a wealth of digital information from your field devices—such as diagnostic data, calibration status, and secondary process variables—without interfering with the primary analog 4-20 mA safety signal.

How the 2770H Enhances Your Safety System

In industrial environments, simply reading a 4-20 mA analog signal isn’t always enough. Modern “smart” field devices can provide a ton of extra data that is crucial for maintenance and asset management. The Triconex 2770H is designed to unlock that information while maintaining the unparalleled safety integrity of the Triconex platform.

Here’s how it works:

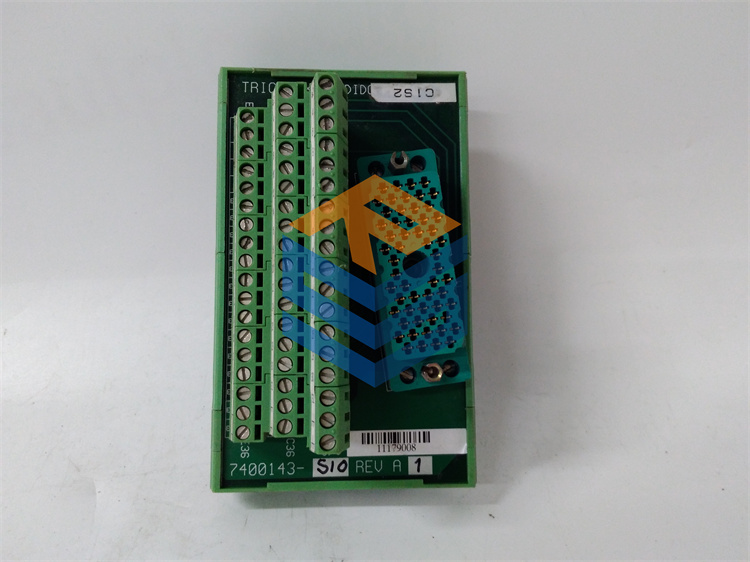

- Seamless HART Integration: The 2770H module incorporates a HART Multiplexer (Triconex 4850), which allows it to simultaneously read the standard 4-20 mA analog signal and the digital HART signal superimposed on the same wires. This happens without any interference, ensuring that the primary safety signal remains untouched and reliable.

- Enhanced Diagnostics: The module extracts valuable diagnostic data from the field devices. This could be anything from a sensor failure to a miscalibration alert. This information is passed through to your asset management system, allowing your team to perform predictive maintenance and address issues before they lead to a process trip.

- High-Density Solution: With 32 input channels, the Triconex 2770H provides a high-density, cost-effective way to integrate a large number of HART-enabled devices into your system.

- Triple-Modular Redundancy (TMR): While the 2770H is the HART interface, it works in conjunction with core Triconex TMR modules like the 3700A and 3721. This ensures that the primary analog input signals benefit from the fault-tolerant, 2-out-of-3 voting architecture that Triconex systems are famous for, providing the highest level of safety and reliability.

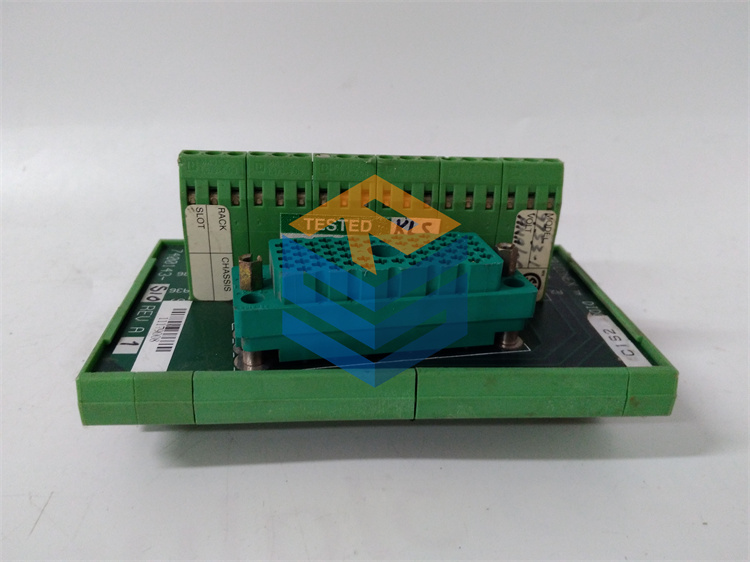

- Hot-Swapping and Diagnostics: Like other Triconex I/O modules, the 2770H is fully hot-swappable. You can replace a faulty module online without shutting down the process or degrading the system’s performance, thanks to continuous diagnostics and built-in redundancy.

Technical Specifications

Application Areas

The Triconex 2770H is an ideal solution for industries that require both safety and sophisticated asset management.

- Refining and Petrochemicals: Used to monitor pressure, temperature, and flow transmitters in critical process units. The HART data provides insights into the health of the transmitters, enabling predictive maintenance.

- Power Generation: In power plants, it connects to smart transmitters on turbines and boilers. The HART protocol allows technicians to remotely access device diagnostics and status, improving operational efficiency and reducing downtime.

- Oil and Gas: In offshore platforms and pipelines, the module connects to HART-enabled sensors for monitoring process variables. The ability to access secondary variables and diagnostic information remotely is a huge advantage in these geographically dispersed and often hard-to-access locations.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922