الوصف

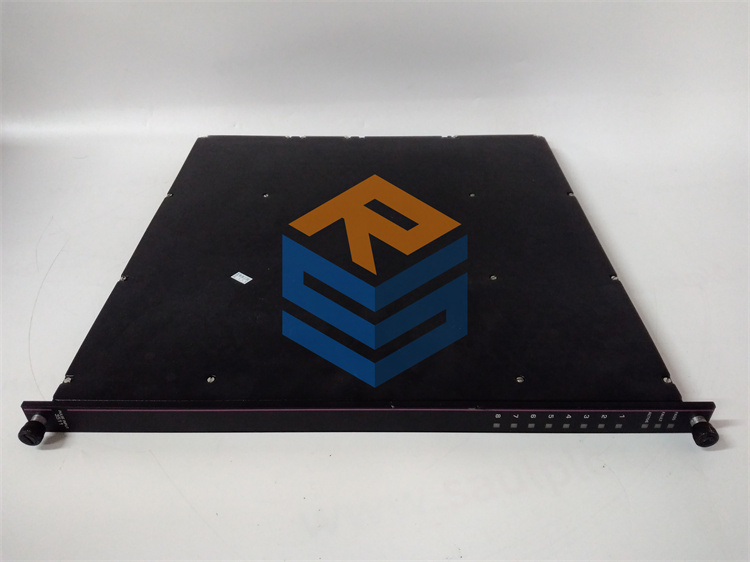

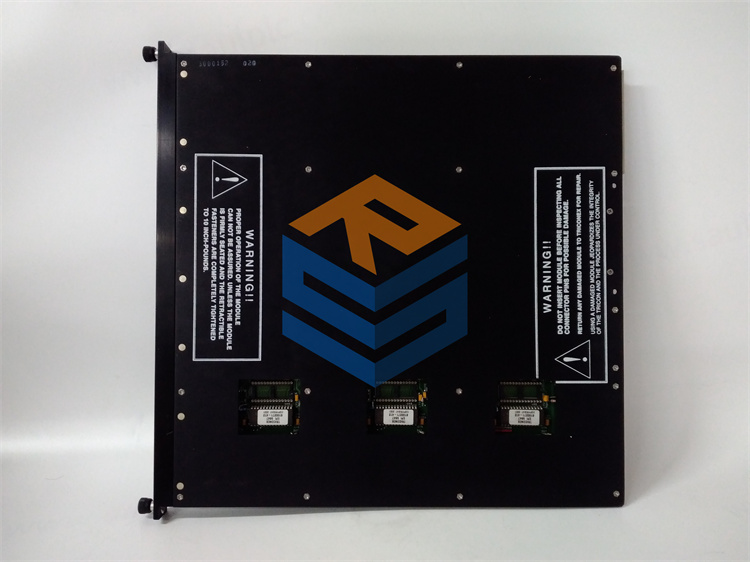

Triconex 3511 Pulse Input Module

The Triconex 3511 is a high-performance pulse input (PI) module designed for use in Triconex safety instrumented systems (SIS). It is engineered to interface with high-frequency pulse-based sensors, providing accurate and reliable signal processing for critical safety applications.

Key Features and Benefits

- Triple Modular Redundancy (TMR): The 3511 module is built on the TMR architecture, which uses three isolated, parallel control channels. The system’s main processors use a two-out-of-three (2oo3) voting process to ensure data integrity and continuous, error-free operation, even in the event of a single component failure.

- High-Frequency Capability: The module is optimized to handle a wide range of pulse frequencies, with a specified range of 20 to 20,000 Hz. This makes it suitable for measuring high-speed events from devices like magnetic speed sensors.

- High-Resolution Measurement: It offers a pulse count resolution of up to 1 microsecond, providing highly precise rate measurements for frequency or RPM calculations.

- 8 Input Points: The module provides 8 points of pulse input, allowing for the connection of multiple sensors. It is designed to work with non-amplified magnetic speed sensors commonly found on rotating equipment such as turbines and compressors.

- Comprehensive Diagnostics: The 3511 includes continuous diagnostics on each of its three channels. A fault indicator is activated if any diagnostic test fails, enabling quick identification and resolution of issues without process interruption.

Common Applications

The Triconex 3511 is used in industries where monitoring high-speed rotating equipment is critical for safety and operational integrity. Typical applications include:

- Turbine Control and Overspeed Protection: Monitoring the rotational speed of gas or steam turbines to prevent dangerous overspeed conditions.

- Compressor Control: Measuring the speed of compressors in oil and gas or chemical plants for safe and efficient operation.

- Flow Measurement: Utilizing pulse-based flow meters to accurately measure the rate of fluid or gas flow in a pipeline or process.

Technical Specifications

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922