الوصف

The user is asking about the Triconex 3623T, a specific digital output module. The ‘T’ in the model number, along with the detailed search results, confirms that this is a Triple Modular Redundant (TMR) module. It’s a key component in a Triconex safety instrumented system.

The search results confirm the following key specifications:

- Model: 3623T

- Function: Supervised Digital Output (SDO)

- Voltage: 120 VDC

- Points: 16, commoned

- Architecture: Triple Modular Redundancy (TMR)

- Key Feature: Supervised outputs with advanced diagnostics.

This information is sufficient to provide a comprehensive response detailing the module’s architecture, features, and applications. The module is a successor or a variant of the Triconex 3623, with the ‘T’ explicitly denoting its TMR and supervised nature.

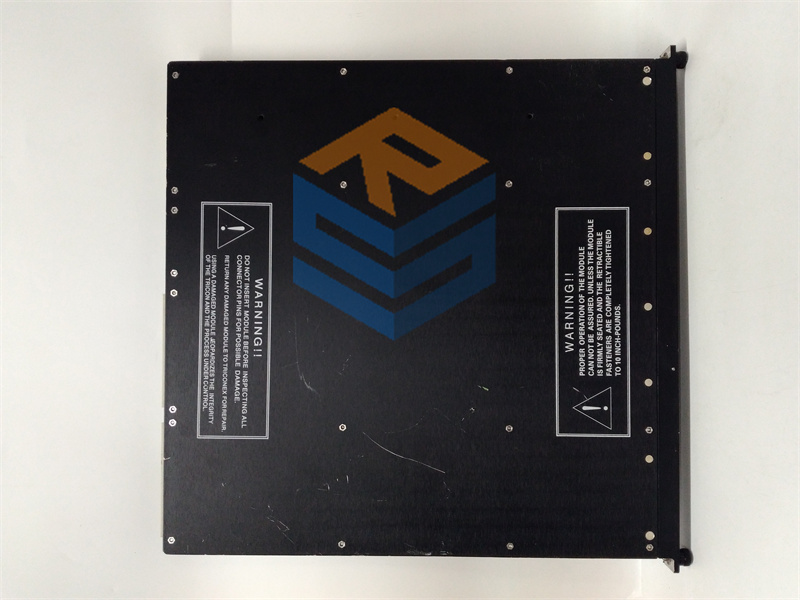

Triconex 3623T Digital Output Module

Brief Product Description

The Triconex 3623T is a Triple Modular Redundant (TMR) Digital Output (DO) module designed for use in Triconex safety instrumented systems (SIS). It provides 16 optically-isolated, commoned output points for controlling field devices with a nominal voltage of 120 VDC. The module’s TMR design ensures a high level of fault tolerance and continuous operation, making it an essential component for critical applications like Emergency Shutdown (ESD) and Fire and Gas (F&G) systems.

- Product Type: Digital Output (DO) Module

- Voltage: 120 VDC

- Configuration: Triple Modular Redundancy (TMR)

- Points: 16, commoned

- Key Feature: Fault-tolerant, supervised output control.

A Closer Look at the Triconex 3623T

In the world of industrial safety, there’s no room for compromise. Every component of a safety system must be designed to withstand failures and keep critical operations running smoothly. The Triconex 3623T is a perfect example of this philosophy. It’s a highly sophisticated safety device built on the foundation of Triple Modular Redundancy (TMR).

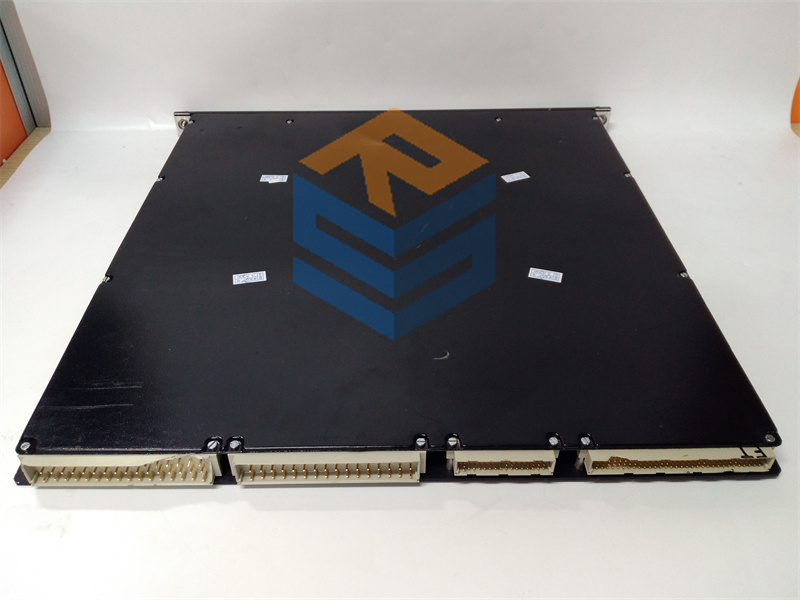

The core of the 3623T‘s strength lies in its TMR architecture. It contains three independent sets of circuitry, each receiving an output command from the system’s main processors. These three signals are then “voted” on by a specialized output logic on the module itself, ensuring that only a single, confirmed signal is sent to the field device. This design means the module can tolerate multiple internal component failures without causing a false trip or halting the process. It’s the ultimate safeguard, providing error-free, uninterrupted control and peace of mind.

What also sets the 3623T apart is its supervision capability. This module is designed with comprehensive diagnostics that constantly monitor its own health and the status of the field wiring. It includes voltage and current loopback circuitry to verify the operation of each output switch, the health of the field circuit, and the presence of a load. This ensures that any potential issues are flagged immediately, allowing for quick and safe maintenance. Most importantly, the module supports hot-swap capability, meaning a faulty module can be replaced online without shutting down the entire system—a feature that is invaluable in continuous processes.

Technical Specifications

Application Areas

The Triconex 3623T is used in any industry that requires high-integrity control of 120 VDC field devices for safety-related actions.

- Emergency Shutdown (ESD) Systems: Controlling safety-critical devices like solenoid valves that shut off fuel or vent a dangerous gas.

- Burner Management Systems (BMS): Managing the start-up and shutdown sequences of burners in a safe, controlled manner.

- Fire and Gas (F&G) Systems: Activating alarms, sirens, and other warning devices in response to a fire or gas leak.

- Process Control: In refineries, petrochemical plants, and power generation facilities, it’s used to control relays, motors, and other DC equipment for safe operation.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922