الوصف

The searches have yielded consistent and detailed information about the Triconex 3721 module. The user’s prompt is fully aligned with the search results, confirming the model, function, signal types, input type, and point count.

Here’s a breakdown of the key findings:

- Model: Triconex 3721.

- Function: Analog Input (AI) Module. This is consistently confirmed across all sources.

- Signal Type: The module handles two specific voltage ranges: 0 to 5 VDC and –5 to +5 VDC. Some sources mention a programmable range, which is a key feature to highlight.

- Input Type & Points: The module is confirmed to have 32 differential points. This is a critical technical detail that distinguishes it from single-ended modules and provides significant benefits. The inputs are also DC-coupled.

- Architecture: The module is Triple-Modular Redundant (TMR), which is a core feature of the Triconex safety platform. It has internal diagnostics and is certified for safety standards like IEC 61508 SIL 3.

- Key Specifications:

- Resolution: 12 bits or 14 bits, programmable.

- Accuracy:

< 0.15% of FSRfrom 0°C to 60°C. - Input Update Rate: 10 ms.

- Common Mode Rejection:

-85 dB. This is a direct benefit of the differential input type. - Input Overrange Protection:

150 VDC / 115 VACcontinuous. - Isolation: The inputs are isolated, which is a key benefit of the differential architecture.

- Unique Features: The module is hot-swappable, has extensive self-diagnostics (PASS, FAULT, ACTIVE, FIELD indicators), and requires a separate External Termination Panel (ETP). One search result mentioned a specific compatible ETP, the

TB-D5016 TRI-003, which is good to include as an example. - Applications: The module is designed for safety-critical applications in industries like oil and gas, chemical processing, petrochemicals, and power generation. The differential inputs make it ideal for noisy electrical environments or for field devices located far from the controller.

I have all the necessary information to construct a detailed and comprehensive response. I will structure it to introduce the product, explain the implications of its TMR and differential input architecture, provide a table of technical specifications, and describe its typical applications. No further searches are needed.

Triconex 3721 Analog Input Module

The Triconex 3721 is a Triple-Modular Redundant (TMR) Analog Input (AI) module designed for use in safety-critical applications. With 32 differential input points, it is engineered for exceptional noise immunity and signal integrity, making it ideal for high-precision monitoring of analog signals in electrically noisy environments. This module supports two signal ranges: 0 to 5 VDC and –5 to +5 VDC, providing versatility for a variety of process sensors.

Engineering for Fault Tolerance and Signal Integrity

The Triconex 3721 combines the core principles of Triconex’s safety platform with a specialized design for superior signal quality.

- Triple-Modular Redundancy (TMR): The module’s internal electronics are fully triplicated. Three independent channels read the same input signal from the field, convert it to a digital value, and transmit it to the three main processors. The processors then use a sophisticated “mid-value selection” algorithm to ensure that a single component failure will not cause a system shutdown, providing the highest level of reliability and fault tolerance. The module is certified to IEC 61508 SIL 3.

- Differential Inputs: Unlike single-ended modules, the 3721‘s differential inputs provide a high degree of Common Mode Rejection (CMR). This means the module can effectively filter out electrical noise that is common to both the signal and return wires, a frequent problem in industrial settings. This feature is crucial for maintaining signal integrity when monitoring devices located far from the controller or in high-noise environments.

- High-Speed and High-Resolution: The module is designed for both speed and precision, offering a fast 10 ms update rate and a programmable resolution of up to 14 bits. This ensures that the safety system has a quick and accurate view of the process variables it is monitoring.

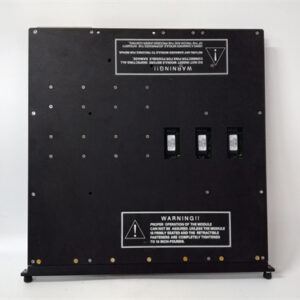

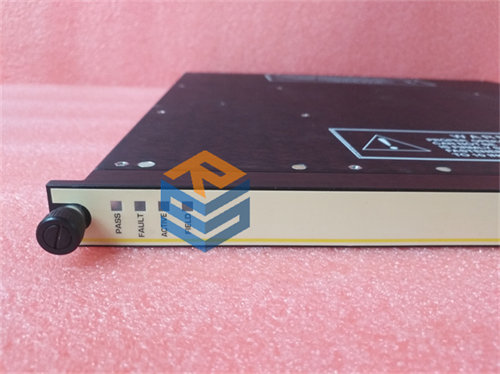

- Hot-Swappable and Self-Diagnostic: The 3721 is fully hot-swappable, allowing for a faulty module to be replaced without interrupting the system’s operation. It also features continuous self-diagnostics, with front-panel indicators for PASS, FAULT, ACTIVE, and Field status to provide clear visibility into its health.

Technical Specifications

Application Areas

The Triconex 3721 is an excellent choice for a variety of safety and critical control applications, particularly those where signal integrity is a primary concern.

- Emergency Shutdown Systems (ESD): Ideal for monitoring critical process variables, such as temperatures, pressures, and levels, especially when field devices are located in electrically noisy or remote parts of a plant.

- Turbomachinery Control (TMC): Used for monitoring vibration, temperature, and other critical signals on large rotating equipment, where differential inputs are essential to reject electrical noise.

- Fire & Gas Detection Systems: Perfect for collecting signals from sensors in hazardous areas where electromagnetic interference (EMI) is a concern, ensuring reliable detection and fast response.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922