الوصف

Triconex 4000103-510 DCS PLC Module

1. Product Name:

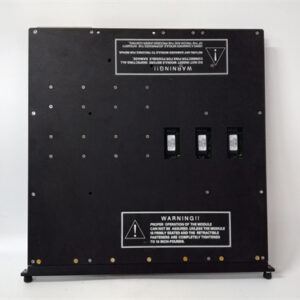

Triconex 4000103-510 DCS PLC Module

2. Product Description:

The Triconex 4000103-510 is a key module in the Triconex family of Distributed Control Systems (DCS) and Programmable Logic Controllers (PLC), primarily used for safety-critical, process automation, and control applications in industries like oil & gas, chemical, petrochemical, power generation, and refining.

Triconex, known for its high-availability and safety-rated systems, offers this module for critical control systems that require fault tolerance, redundancy, and real-time monitoring. The 4000103-510 module is part of the Tricon™ system, a platform renowned for its fail-safe design, continuous diagnostics, and hot-swapping capabilities. It is especially effective in environments where safety integrity is paramount, and downtime must be minimized.

The module is designed to integrate seamlessly into the Triconex Tricon Safety System, which is built for mission-critical applications in industries that cannot afford any system failures. Triconex‘s approach to high-reliability and redundancy ensures that the 4000103-510 module plays a vital role in achieving safe and reliable operation.

3. Product Parameters and Specifications:

Model Number:

- Triconex 4000103-510

General Specifications:

- Manufacturer: Triconex (A part of Schneider Electric, specializing in safety, control, and automation solutions)

- Product Type: DCS/PLC Module

- System Compatibility: Compatible with Tricon™ and Triconex Safety Systems (Safety Instrumented Systems)

- Primary Application: Used in safety-critical process control and monitoring for industries such as oil & gas, chemical, petrochemical, refining, and power generation.

Physical and Mechanical Characteristics:

- Form Factor: Rack-mounted design (compatible with Triconex’s chassis/rack systems).

- Size: Typically 6.8 x 3.5 x 1.5 inches (varies by exact configuration).

- Weight: Approximately 1.2 to 1.5 kg (varies with configuration).

- Mounting: Standard chassis slot for easy installation.

- Cooling: The module features passive cooling (without the need for external cooling units).

- Power Supply: 24V DC (common for DCS/PLC modules in the Triconex range).

Operating Conditions:

- Operating Temperature: 0°C to 60°C (32°F to 140°F).

- Storage Temperature: -40°C to 85°C.

- Humidity: Designed for operation in environments with 10% to 95% non-condensing humidity.

- Vibration Resistance: Designed for industrial environments, with moderate vibration tolerance.

- Shock Resistance: Robust enough to withstand typical industrial shock conditions.

Communication and I/O Capabilities:

- Communication Protocols:

- Supports Triconex proprietary protocols for communication with other Tricon modules and external systems.

- Redundant Communication: Built-in support for redundant communication paths to enhance reliability and fault tolerance.

- I/O Types:

- Discrete I/O: Supports both digital inputs and digital outputs for binary devices (e.g., switches, relays).

- Analog I/O: Provides analog input/output for continuous process control signals (e.g., pressure, flow, temperature sensors).

- Redundant I/O: The module supports redundant configurations of inputs and outputs for high availability and fault tolerance.

Key Features:

- Fail-Safe Design: The 4000103-510 module is engineered for high safety integrity, meeting SIL3 (Safety Integrity Level 3) standards, making it suitable for Safety Instrumented Systems (SIS).

- Redundant Processing: Dual processor architecture for continuous fault detection and automatic failover, ensuring that the system remains operational even if one processor fails.

- Hot-Swappable: The 4000103-510 module can be replaced without shutting down the system, reducing downtime during maintenance.

- Self-Diagnostics: Continuous system monitoring and self-checking, with diagnostics that can provide real-time feedback on system status and operational health.

Fault Tolerance and Reliability:

- Fault-Tolerant Architecture: Designed for high availability, the module operates with a dual-redundant system, which helps in avoiding system shutdowns due to hardware failures.

- Built-In Testing: Features built-in self-test and self-diagnosis routines, providing fault tolerance and ensuring system integrity.

- Alarm and Event Logging: Detailed event logging and diagnostic alarms for troubleshooting and performance tracking.

Safety Features:

- Safety Integrity: Certified to meet SIL 3 requirements (IEC 61508) for functional safety.

- Safety Applications: Ideal for emergency shutdown systems (ESD), fire and gas detection systems, and other critical safety applications.

- Redundant Power Supplies: The module can operate with redundant power supplies, offering fail-safe operation during power issues.

Environmental Compliance:

- RoHS Compliant: Free from hazardous materials per the RoHS (Restriction of Hazardous Substances) directive.

- UL and CE Certification: Meets global safety and regulatory standards for industrial systems.

4. Applications:

The Triconex 4000103-510 DCS/PLC module is used in mission-critical systems where safety and fault tolerance are of utmost importance. Common applications include:

-

Oil & Gas Industry:

- For production and refining operations, ensuring safe monitoring and control of processes such as drilling, pumping, compressor control, and emergency shutdown systems (ESD).

-

Chemical and Petrochemical Plants:

- Used for the safe operation of reactors, dosing systems, and chemical processing plants, where failure could lead to hazardous situations.

-

Power Generation:

- Integral for power plant safety applications, such as boiler control, turbine monitoring, and emergency trip systems.

-

Refining and Metallurgy:

- Ensures the safe control of refining processes, with applications in crude oil refining, chemical distillation, and reactor control.

-

Industrial Automation and Control:

- Provides robust control for automated systems, where downtime is not acceptable, and safety must be ensured at all times.

-

Water and Wastewater Treatment:

- For controlling critical water treatment processes with a focus on safety and continuous system monitoring.

5. Conclusion:

The Triconex 4000103-510 DCS/PLC module is a powerful and highly reliable solution for safety-critical applications in industrial automation. With its fail-safe design, redundant systems, hot-swapping capability, and SIL3 compliance, it ensures both reliability and safety for demanding environments. Whether it’s controlling safety processes in oil & gas, power generation, or chemical manufacturing, the 4000103-510 module is engineered to provide high availability and fault tolerance in mission-critical systems.

PM571-ETH

PM581-ARCNET

PM581-ETH

PM582-ARCNET

PM582-ETH

PM590-ARCNET PLC DCS

PM590-ETH

PM591-ARCNET

PM591-ETH PLC DCS

CM572-DP

CM574-RS

CM574-RCOM

CM575-DN

CM577-ETH

CM578-CN PLC DCS

CM579-PNIO

CM579-ETHCAT

DC541-CM

TB511-ETH

TB511-ARCNET

TB521-ETH

TB521-ARCNET

TB541-ETH

TA521 PLC DCS

TA523

TA524

TA525

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922