الوصف

The user is asking about the Triconex 9673-810. Based on the naming convention of Triconex products, the “96” prefix indicates this is an External Termination Panel (ETP), which is an interface between a Triconex I/O module and field wiring. The “-810” suffix consistently points to a 24 VDC voltage rating. The “73” in the model number suggests it is designed for a specific type of digital I/O.

This panel is a vital part of the Triconex system, designed to simplify wiring, improve reliability, and streamline maintenance.

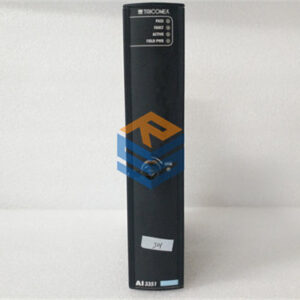

Triconex 9673-810 Digital I/O Termination Panel

Brief Product Description

The Triconex 9673-810 is an External Termination Panel (ETP) designed to streamline the wiring of 24 VDC Digital I/O modules in a Triconex safety system. This panel serves as a robust and organized interface between the system’s I/O modules and the field devices they monitor and control. By simplifying the connection of field wiring, the 9673-810 reduces installation time, minimizes human error, and facilitates maintenance in critical industrial environments.

- Product Type: External Termination Panel (ETP)

- Operating Voltage: 24 VDC

- Number of Points: Varies, typically 16 or 32

- Key Feature: Screw-terminal design for simplified field wiring.

A Closer Look at the Triconex 9673-810

In complex industrial facilities, the physical wiring from field devices like switches, valves, and sensors can be a logistical challenge. The Triconex 9673-810 is the solution to this problem. As an essential part of the Triconex ecosystem, this panel acts as a reliable and organized bridge, connecting the Digital I/O module to the equipment it interacts with. It’s a critical, though often overlooked, component that ensures the integrity and reliability of the entire system.

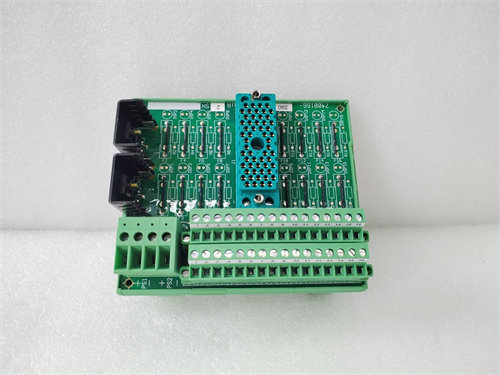

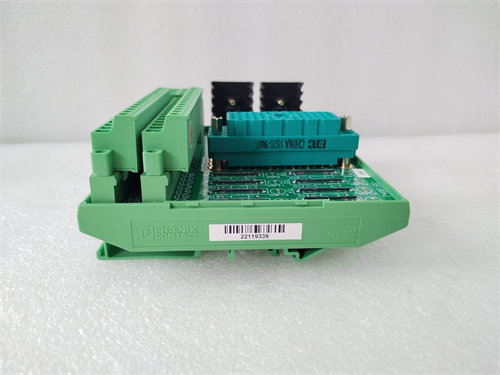

The primary function of the Triconex 9673-810 is to simplify wiring and maintenance. Instead of directly wiring individual wires to the back of a sensitive I/O module, you connect the field wires to the larger, more accessible screw terminals on the panel. The ETP then connects to the I/O module via a pre-fabricated, high-quality cable, minimizing the chance of wiring errors during installation. This structured approach not only saves significant time during setup but also provides a clean, easy-to-manage layout that is vital for quick and safe maintenance.

For engineers and maintenance staff, the benefits of this design are immense. It simplifies troubleshooting, as all field connections are neatly organized on a single panel. If you need to replace a faulty I/O module, you can do so by simply disconnecting the main cable from the panel and removing the module, all without ever touching the individual field wires. This hot-swap friendly design drastically reduces downtime and allows for maintenance to be performed without interrupting the process—a critical feature for plants that operate around the clock.

Technical Specifications

Application Areas

The Triconex 9673-810 is used wherever a Triconex safety system is implemented. Its primary role is to provide a clean and reliable interface for a variety of digital I/O signals that monitor and control field equipment.

- Emergency Shutdown (ESD) Systems: A core application is providing a reliable, organized point of connection for all the field sensors and output devices that must be monitored and activated during an emergency shutdown.

- Process Industries: In chemical plants, refineries, and pipelines, it’s used to connect signals from switches and to control valves, relays, and other critical equipment.

- Power Generation: It organizes connections for boiler status, turbine trip signals, and generator alarms.

- Fire and Gas Systems (FGS): In FGS applications, the panel connects the Triconex modules to fire and gas detectors and controls sirens and shutdown relays.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922