الوصف

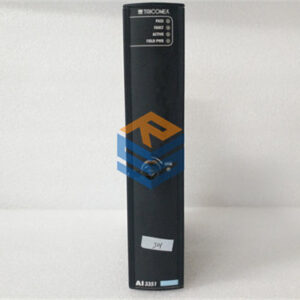

The TRICONEX MP3009 (often referred to as Triconex 3009 or Triconex MP-3009) is a High-Performance Main Processor (MP) module, also known as a Unified Main Processor (UMP), designed for the Triconex Safety Instrumented System (SIS). It is a central processing unit (CPU) within the Triconex architecture.

This module is the “brain” of the Triconex safety system, responsible for executing the safety application logic, performing diagnostics, and managing communication within the Triple Modular Redundant (TMR) framework. It’s a critical component for achieving the highest levels of safety integrity (up to Safety Integrity Level 3 – SIL 3).

Top 10 SEO-Optimized Headings:

- TRICONEX MP3009: High-Performance Main Processor for SIL 3 Safety Systems.

- The Brain of Safety: Unlock Reliability with the TRICONEX 3009 UMP Module.

- TRICONEX MP3009: Fault-Tolerant Processing for Critical Industrial Applications.

- Advanced Diagnostics & Logic: Leveraging the TRICONEX 3009 for SIS.

- Why Choose TRICONEX MP3009: Maximizing System Integrity and Uptime.

- TRICONEX MP3009: The Core of Emergency Shutdown, Fire & Gas, and BMS.

- Dual-Core Architecture: Key Features of the TRICONEX MP3009 Processor.

- TRICONEX MP3009: Essential for Oil & Gas, Chemical, and Power Generation Safety.

- Optimize Your Triconex System: The Versatility of the TRICONEX MP3009.

- Industrial Safety: Ensuring Ultimate Performance with the TRICONEX MP3009.

Brief Product Description (for Detail Pages and Search Results):

The TRICONEX MP3009 (Unified Main Processor) is a high-performance, dual-core main processor module for Triconex Safety Instrumented Systems (SIS). It is designed to execute safety application logic with speed and reliability, supporting fault-tolerant operation up to Safety Integrity Level 3 (SIL 3). Featuring advanced diagnostics, faster response times, and flexible configuration, the MP3009 enhances the overall processing power and integrity of Triconex systems, making it ideal for critical safety applications in industries like oil & gas, chemical, and power generation.

- Product Type: Main Processor (MP) / Unified Main Processor (UMP) Module

- Model Number: MP3009 (also referred to as Triconex 3009)

- Processor Architecture: Dual-core for enhanced performance.

- Safety Integrity Level (SIL): Up to SIL 3 certified.

- Key Features: Triple Modular Redundancy (TMR) support (as part of the overall system), advanced diagnostics, faster response times, hot-swappable (within the TMR system).

- Compatibility: Triconex Tricon series controllers and I/O modules.

- Applications: Emergency Shutdown Systems (ESD), Fire & Gas (F&G) Systems, Burner Management Systems (BMS), critical process control in highly demanding industrial environments.

Detailed Product Description:

In any safety-critical system, the processor is the “brain” that receives inputs, executes logic, and commands outputs. For the Triconex Safety Instrumented System (SIS), the TRICONEX MP3009 is precisely that brain, engineered to deliver unparalleled performance and reliability. It’s not just a single CPU; it’s a sophisticated module designed to operate within a Triple Modular Redundant (TMR) architecture, ensuring that safety functions are executed flawlessly even in the presence of component failures.

I’ve seen many industrial incidents that could have been prevented with a more robust and responsive safety system. The speed and diagnostic capabilities of the main processor are often the unsung heroes in preventing these events. The TRICONEX MP3009 directly addresses this need. Its advanced architecture and faster processing power mean quicker response times to hazardous conditions, allowing the safety system to initiate protective actions with minimal delay. This directly translates to enhanced safety for personnel, assets, and the environment, and reduced risk of costly operational disruptions.

The Heart of Triple Modular Redundancy (TMR):

The TRICONEX MP3009 operates as one of the three independent, identical processors within the Triconex TMR architecture. Here’s how it ensures ultimate reliability:

- Three Independent Processors: A Triconex system equipped with the MP3009 will typically have three MP3009 modules running in parallel. Each module independently executes the same safety application program.

- Hardware-Implemented Voting: The results from these three processors are continuously compared and voted on at various stages (inputs, internal processing, and outputs) by specialized hardware.

- Fault Tolerance: If one of the MP3009 modules develops an internal fault or produces a divergent result, the voting mechanism will identify and mask that fault. The system continues to operate correctly, uninterrupted, using the results from the two healthy processors. This allows for online repair (hot-swapping the faulty module) without compromising system operation.

- Self-Diagnostics: Each MP3009 module performs extensive self-diagnostics continuously, monitoring its own health and the integrity of its internal components. This ensures that any potential issues are detected quickly.

Enhanced Performance and Features:

The TRICONEX MP3009 represents an evolution in Triconex processor technology, offering several key advancements:

- Dual-Core Architecture: Provides enhanced processing power compared to previous generations, allowing for faster scan times and more complex safety logic execution. This translates to quicker response times to critical events.

- Advanced Diagnostics: Offers comprehensive fault detection and status reporting, giving operators and maintenance personnel detailed insights into the system’s health. This reduces troubleshooting time and improves overall system availability.

- Flexible Configuration: Highly configurable to meet a wide range of safety applications, including Emergency Shutdown (ESD), Fire & Gas (F&G) detection, and Burner Management Systems (BMS).

- Communication Capabilities: Supports multiple communication protocols (often via dedicated communication modules in the same chassis) for seamless integration with Distributed Control Systems (DCS), SCADA systems, and Human Machine Interfaces (HMIs).

- Hot-Swappable: Designed to be hot-swapped (replaced while the system is online) in the event of a fault, further minimizing downtime and ensuring continuous operation.

- IEC 61508 SIL 3 Certification: Certified to achieve Safety Integrity Level 3, the highest level of safety for programmable electronic systems, indicating its suitability for the most critical industrial safety applications.

Technical Specifications (Typical):

Applications:

The TRICONEX MP3009 is at the core of the most critical safety applications across various heavy industries where uninterrupted operation and human safety are paramount:

- Oil & Gas (Upstream, Midstream, Downstream):

- Emergency Shutdown Systems (ESD): Initiating plant-wide or unit-specific shutdowns in response to detected hazards.

- Fire & Gas (F&G) Systems: Controlling deluge systems, activating alarms, and shutting down fuel lines upon detection of fire or gas leaks.

- Wellhead Control and Pipeline Safety: Managing high-pressure situations and ensuring safe operations.

- Petrochemical and Chemical Plants:

- Process Interlocks: Ensuring safe sequencing of operations and preventing hazardous conditions (e.g., preventing mixing of incompatible chemicals).

- Reactor safety and hazardous material handling.

- Power Generation (Fossil Fuel and Nuclear):

- Burner Management Systems (BMS): Ensuring safe startup, operation, and shutdown of large industrial burners to prevent explosions.

- Turbine protection and generator trip systems.

- Reactor control and protection in nuclear power plants.

- Mining:

- Controlling safety systems for ventilation, fire suppression, and emergency shutdowns in hazardous underground or surface operations.

- Pharmaceutical Manufacturing:

- Ensuring safe control of critical processes, cleanroom environments, and potentially hazardous chemical reactions.

Related Products:

The TRICONEX MP3009 is the central processing unit, and it works in conjunction with a variety of other Triconex components and external systems:

- Triconex I/O Modules (e.g., 3501E, 3604E, 3708EN, 3506X, 3626X): These modules connect to field devices and provide the input data to the MP3009 and receive commands from it.

- Triconex Communication Modules (e.g., 4329, 4351B, 4355X, 4609, 4610X): These modules enable the MP3009 to communicate with external systems (DCS, SCADA, HMIs) and other Triconex systems.

- Triconex Chassis (e.g., 8110, 8111, Tricon CX Main Chassis): The physical enclosures that house the MP3009 and other Triconex modules.

- Triconex Power Supplies (e.g., 83xx series): Provide the necessary operating power for the Triconex system, including the MP3009.

- TriStation Software: The engineering workstation software used to configure, program, diagnose, and maintain the Triconex system, interacting directly with the MP3009.

- Schneider Electric EcoStruxure Triconex Safety Systems: The broader portfolio of Schneider Electric safety solutions that the MP3009 is a core part of.

- Distributed Control Systems (DCS) / SCADA Systems (e.g., Emerson DeltaV, Honeywell Experion PKS, ABB Ability System 800xA): Higher-level control systems that monitor the status of the Triconex SIS (via communication modules) and often integrate its data for overall plant operations.

- Field Devices (Sensors, Actuators): The physical components in the process that send signals to and receive commands from the Triconex system (via I/O modules).

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922