الوصف

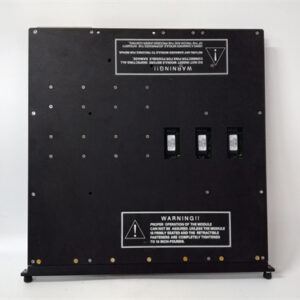

Triconex Redundant Safety PLC System 2351 and 2402

The Triconex 2351 and 2402 are redundant safety Programmable Logic Controllers (PLCs) designed for high-availability and safety-critical applications in various industries. This system utilizes a triple-modular redundant (TMR) architecture, ensuring fail-operational performance and maximizing uptime, even in the event of component failure. The Triconex 2351 typically serves as the main processing unit, while the 2402 often acts as an I/O module, although their configurations are flexible depending on system needs. This robust architecture is a hallmark of the Triconex brand.

Product Description

The Triconex 2351/2402 system provides a highly reliable and safe control solution for complex industrial processes. The 2351 processor unit employs advanced safety algorithms and self-diagnostic capabilities to ensure continuous operation and prevent hazardous situations. It boasts a high processing speed, facilitating real-time control of critical functions. The 2402 I/O module expands the system’s input/output capacity, allowing for seamless integration with a wide range of field devices. The system’s modular design allows for customization to fit specific application requirements. The combination of the 2351 and 2402 provides a scalable and flexible safety system suitable for various levels of complexity and criticality. The inherent redundancy of the Triconex 2351/2402 system makes it a particularly attractive option for applications where downtime is costly or dangerous.

Product Parameters

| Parameter | Description | Value/Range | Units |

|---|---|---|---|

| Processor | Triconex 2351 | Triple Modular Redundant (TMR) | |

| I/O Module | Triconex 2402 | Varies based on configuration | |

| Input Channels | Configurable | Depends on I/O modules | |

| Output Channels | Configurable | Depends on I/O modules | |

| Processing Speed | High, suitable for real-time applications | Varies depending on configuration | |

| Safety Integrity Level (SIL) | Achievable up to SIL 3 | ||

| Communication | Various protocols (e.g., Ethernet, Profibus) | ||

| Power Supply | Redundant power supplies | ||

| Environmental Rating | Varies depending on specific module configuration | Consult datasheet for detailed specifications |

Advantages and Features

- High Availability: TMR architecture ensures continuous operation even with component failures.

- Safety Integrity: Designed to meet high safety integrity levels (SILs).

- Scalability: Modular design allows for customized configurations.

- Real-time Performance: High processing speed for critical applications.

- Advanced Diagnostics: Self-diagnostic capabilities for early fault detection.

- Easy Integration: Wide range of communication protocols for seamless integration.

- Proven Reliability: Extensive use in various industries for decades.

Application Areas and Case Studies

Triconex 2351/2402 systems are widely used in safety-critical applications across diverse industries, including:

- Oil and Gas: Process safety systems in refineries and offshore platforms.

- Power Generation: Safety systems for power plants and substations.

- Chemical Processing: Safety instrumented systems (SIS) for chemical plants.

- Mining: Emergency shutdown systems and safety monitoring.

A case study example would be the implementation of a Triconex 2351/2402 based safety system in a large refinery to control emergency shutdown procedures, ensuring the safety of personnel and equipment during hazardous situations.

Competitor Comparison

Direct competitors to Triconex include Siemens, Rockwell Automation, and Schneider Electric. While these companies offer comparable safety PLCs, Triconex is often preferred for its robust TMR architecture, specifically designed for high-reliability, safety-critical applications where the extremely high uptime and safety requirements exceed what more general purpose PLCs can offer. Detailed comparison requires specification of the exact competing products and a thorough analysis of features, performance, and cost.

Selection Advice

The selection of a Triconex 2351/2402 system should consider the specific safety requirements, I/O needs, and communication protocols of the application. A detailed risk assessment and functional safety analysis are essential for determining the appropriate SIL level and configuration. Consult with a Triconex specialist to determine the optimal system configuration.

Precautions

Always follow the manufacturer’s installation and operating instructions. Regular maintenance and testing are crucial to ensure continued safety and reliability. Proper grounding and power supply connections are essential. Ensure compatibility with other system components.

We are your trusted partner. We offer Triconex 2351/2402 and other automation spare parts sales and technical support. We offer special discounted prices. Contact us, and we will be happy to serve you.

TRICONEX+2351 2402

BERKELEY PROCESS CONTROL INC BAM-432 TURBO

A-B 1756-OF8

FOXBORO FBMSVH

A-B 1756-L61

A-B 1756-EN2T

B&R ECR165

A-B 2711-K6C8

SANYO PMM-BD-57025-1

ABB 5SHX1445H0001

GE IC693CPU374

A-B 1756-L63/B

EPRO MMS6110

MODBUS MVI69E-MBS

TRICONEX 8312

IWAKI SC-1

KUKA KPS-600/20-REL

A-B 1746-NO8I

ABB XI16E1-F4.0

SCHNEIDER HMIGTO6310

A-B 1746-NO8I

A-B 1756-L63

OMRON NT631C-ST153-EV3

A-B MPL-B4530K-MJ72AA

HONEYWELL CC-PAIX01

GE IC660EBR101

BENDER RCM470DD

EPRO MMS6312

KEBA TT081 02203-7614

A-B 1756-EN2T

WESTINGHOUSE 1C31125G02

EMERSON VE4003S6B1

PHILIPS PE1928/71

FORCE PMC422FP

YASKAWA JRMSP-PS60V

Heidenhain ROD 426.0003 2500

WESTINGHOUSE 1C31122G01

TOSHIBA ST2600GXH25A

A-B 1769-L33ER

Cutler Hammer KW3400F

HONEYWELL TC-PRR021

EMERSON KJ3223X1-BA1

A-B 1756-EN2TR

HONEYWELL TK-PRR021

BENTLY 3500/94-14-01-00

A-B 1785-BCM

NI PCI-6254

SIEMENS 1FK7081-2AC71-1UA0-Z N05

PROSOFT MVI69-MCM

ECKARDT SRI986-BIDS7EAANA

和利时 FM020

MOTOROLA MVME162-220

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922