الوصف

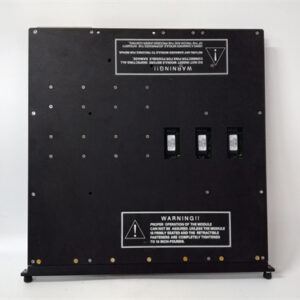

Product Name: TRICONEX 3564

Product Description

TRICONEX 3564 is an advanced PLC automation module designed by Schneider Electric, offering exceptional performance and reliability for critical process automation applications. This module is part of the TRICONEX safety system, which focuses on high availability and fault tolerance, making it indispensable in industries where safety and uptime are paramount. The TRICONEX 3564 is crafted to integrate seamlessly with various control systems while ensuring ease of maintenance and operation.

Product Parameters

- Input Voltage: 24VDC

- Input Type: Digital

- Output Type: Relay and Transistor outputs

- Temperature Range: -20°C to 60°C

- Dimensions: Compact and modular design

- Communication Protocols: Supports various industrial protocols

- Mounting: DIN Rail mountable for easy installation

Advantages and Features

The TRICONEX 3564 boasts several features that enhance its utility:

- Safety and Reliability: Designed for use in safety-critical environments, ensuring your operations remain uninterrupted.

- Modular Design: The modular nature allows for tailored configurations to meet specific application needs.

- Easy Integration: Compatible with a wide range of existing automation systems and equipment.

- Robust Performance: Withstanding harsh industrial conditions, it delivers reliable performance over extended periods.

- User-Friendly: Simplifies programming and troubleshooting processes through intuitive interfaces.

Application Fields and Case Studies

The TRICONEX 3564 is widely used in various industries such as:

- Oil and Gas: For monitoring and controlling safety systems in refineries and offshore platforms.

- Chemical Processing: Ensuring safe operation and compliance with stringent environmental regulations.

- Power Generation: Monitoring critical parameters in power plants to enhance safety and operational efficiency.

A notable case study involves the deployment of the TRICONEX 3564 in a large-scale petrochemical plant where it significantly reduced downtime and improved safety compliance, leading to enhanced operational efficiency.

Competitive Comparison

When comparing the TRICONEX 3564 to other brands such as Allen-Bradley and Siemens, it stands out due to:

- Superior Safety Features: The TRICONEX 3564 is specifically engineered for safety applications, making it a preferred choice in high-risk environments.

- Better Fault Tolerance: Its dual-channel architecture ensures continued operation even in the event of hardware failures.

- Comprehensive Support: Schneider offers extensive technical support and resources, which is critical in industrial applications.

Selection Advice

When selecting the TRICONEX 3564, consider the following:

- Application Needs: Assess the specific safety and control requirements of your project.

- System Compatibility: Ensure that your existing systems can integrate with the TRICONEX 3564 to avoid complications.

- Scalability: Evaluate whether the modular design of the TRICONEX 3564 meets future expansion needs.

Precautions

While implementing the TRICONEX 3564, ensure:

- Proper Installation: Follow the manufacturer’s guidelines for installation to guarantee optimal performance.

- Regular Maintenance: Perform routine checks and maintenance to prolong the life of your PLC modules.

- Training: Provide adequate training for staff to operate the new system effectively, thus maximizing its benefits.

We are your trusted partner, providing sales and technical support for the TRICONEX 3564 and other automation spare parts. Enjoy special discount prices by contacting us today; we are dedicated to serving you!

TRICONEX+3564

| APP-PFB-PCI PLC DCS |

| APP-PFB-PCU PLC DCS |

| APP-PFB-PCU-C PLC DCS |

| APP-PFB-PCI PLC DCS |

| APP-PFB-PCIE PLC DCS |

| APP-PF2-PCI PLC DCS |

| APP-ETH-PCU PLC DCS |

| APP-ETH-PCU-C PLC DCS |

| APP-EPB-PCU PLC DCS |

| APP-EPB-PCI PLC DCS |

| APP-EPB-PCIE PLC DCS |

| APP-ESR-PCU PLC DCS |

| APP-ETH-PCU-AB PLC DCS |

| APP-EPB-PCU-AB PLC DCS |

| APP-ESR-PCU-AB PLC DCS |

| APP-DRV-AB PLC DCS |

| APP-MBP-PCI PLC DCS |

| APP-MBP-PCI-RC PLC DCS |

| APP-CON-MBP PLC DCS |

| APP-FIP-PCI PLC DCS |

| APP-CON-FIP PLC DCS |

| 5136-SD-PCI-U PLC DCS |

| APP-SR1-PCI PLC DCS |

| APP-SR1-PCIE PLC DCS |

| APP-SR1-PCU PLC DCS |

| APP-SR1-PCU-C PLC DCS |

| APP-SR2-PCI PLC DCS |

| APP-SR4-PCI PLC DCS |

| APP-WEB-SER-M PLC DCS |

| APP-WEB-PFB-M PLC DCS |

| APP-WEB-PFB-MTH PLC DCS |

| APP-WEB-SER-MTH PLC DCS |

| APP-WEB-TH PLC DCS |

| APP-ESP-GTW PLC DCS |

| APP-ESR-GTW PLC DCS |

| APP-UPG–TH PLC DCS |

| APP-PNT-GTW-P PLC DCS |

| APP-INT-485-N PLC DCS |

| APP-INT-232-N PLC DCS |

| APP-INT-232-G PLC DCS |

| APP-INT-485-G PLC DCS |

| APP-INT-CL2-N PLC DCS |

| APP-INT-PFB-G PLC DCS |

| APP-INT-MBP PLC DCS |

| APP-INT-AMP PLC DCS |

| APP-INT-PFB-N PLC DCS |

| APP-SBX-BRD PLC DCS |

| APP-SBX-BXD PLC DCS |

| APP-SBX-BXR PLC DCS |

| APP-GTW-S4D PLC DCS |

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922