الوصف

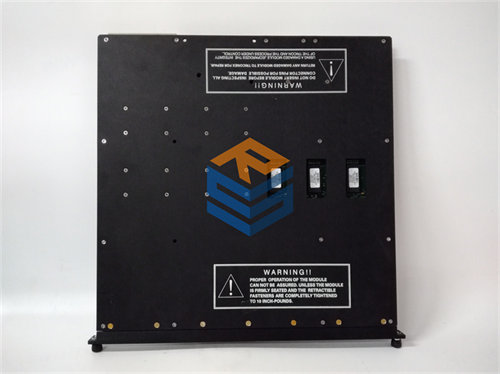

The TRICONEX 3604E is a Triple Modular Redundant (TMR) Digital Output (DO) Module for the Triconex Safety Instrumented System (SIS). This is a critical component used in highly demanding industrial applications where safety and continuous operation are paramount.

It’s designed to receive output signals from the Triconex main processors and then, through a robust voting mechanism, generate a single, highly reliable output signal to control field devices. Its TMR architecture means it has built-in redundancy to ensure operation even in the presence of single faults.

Top 10 SEO-Optimized Headings:

- TRICONEX 3604E: TMR Digital Output Module for Critical Safety Systems.

- Uninterrupted Control: The TRICONEX 3604E for Industrial Safety Applications.

- TRICONEX 3604E: Fault-Tolerant Digital Outputs for Enhanced Reliability.

- Precision & Protection: Leveraging the TRICONEX 3604E in SIS Solutions.

- Why Choose TRICONEX 3604E: Maximizing Availability in Harsh Environments.

- TRICONEX 3604E: The Core of Emergency Shutdown and Fire & Gas Control.

- Hot-Swappable & Self-Diagnosing: Key Features of the TRICONEX 3604E DO Module.

- TRICONEX 3604E: Essential for Nuclear Power, Oil & Gas, and Chemical Processes.

- Optimize Your Safety System: The Versatility of the TRICONEX 3604E DO Module.

- Industrial Control: Ensuring Integrity with the TRICONEX 3604E Digital Output.

Brief Product Description (for Detail Pages and Search Results):

The TRICONEX 3604E is a 16-point, 24 VDC, optically isolated, Triple Modular Redundant (TMR) Digital Output (DO) module. It’s a key component of Triconex Safety Instrumented Systems (SIS), providing fault-tolerant control for critical industrial applications. With its TMR architecture and advanced diagnostics, the 3604E ensures high availability and reliable operation even in the event of component failures, making it ideal for emergency shutdown, fire & gas, and process control applications requiring the highest integrity.

- Product Type: Digital Output (DO) Module

- Channels: 16 points

- Voltage: 24 VDC (some sources also mention 24 VAC, but 24VDC is more common for outputs in safety systems).

- Key Feature: Triple Modular Redundancy (TMR), Opto-Isolated, Non-Commoned outputs.

- Compatibility: Triconex Tricon series controllers (e.g., Tricon v9, Tricon CX). Requires an external termination panel (ETP).

- Applications: Emergency Shutdown (ESD), Fire & Gas (F&G), Burner Management Systems (BMS), critical process control in industries like Oil & Gas, Petrochemical, Chemical, and Nuclear Power.

Detailed Product Description:

In the realm of industrial safety, where even a momentary failure can have catastrophic consequences, systems must be built with uncompromising reliability. This is the very essence of the TRICONEX 3604E Digital Output Module. It’s not just a simple switch; it’s a highly sophisticated, fault-tolerant component that ensures critical commands are executed precisely and reliably, even in the face of internal component failures. Think of it as a meticulously designed safeguard, ensuring that when the system commands an action, that action will occur, without fail.

I’ve personally witnessed the immense pressure engineers face in safety-critical environments. Every component chosen for an Emergency Shutdown System (ESD) or a Fire & Gas (F&G) system must meet the highest standards of integrity. The TRICONEX 3604E directly addresses this need. Its built-in redundancy and advanced diagnostics provide an unparalleled level of confidence. This means peace of mind, knowing that your safety system will perform its duty when it matters most, protecting personnel, assets, and the environment.

The Power of Triple Modular Redundancy (TMR):

The core of the TRICONEX 3604E‘s reliability lies in its Triple Modular Redundancy (TMR) architecture. Here’s how it works:

- Three Channels, One Output: The module receives output signals from each of the three main processors (in a TMR Triconex controller) on three separate channels.

- Quadruplicated Voting Circuitry: Within the module, special “quadruplicated voting circuitry” then processes these three signals. This means it’s not just checking if two out of three agree; it has an even more robust internal structure.

- Voted Output: The circuitry votes on the signals and produces a single, highly reliable output signal that is sent to the field device.

- Fault Tolerance: This design ensures that the module can continue to operate correctly even if one of its internal components or channels fails. The module is guaranteed to operate properly in the presence of a single fault and may continue to operate with certain kinds of multiple faults.

Advanced Diagnostics and Protection:

Beyond TMR, the TRICONEX 3604E incorporates features that enhance its integrity and simplify maintenance:

- Voltage Loop-back Circuitry: Each output switch has a dedicated voltage loop-back circuit. This circuit continuously verifies the operation of the output switch independently of whether a load is present. It can detect “latent faults” – issues that might not be immediately apparent but could lead to future failure.

- Load/Fuse Alarm Indicator: If the detected field voltage doesn’t match the commanded output state, or if a fuse blows (each output has a 2.5A fast-acting fuse on the external termination panel), an alarm indicator is activated.

- Continuous Self-Diagnostics: Ongoing diagnostics are performed on every channel and circuit. A “Fault” indicator activates if any diagnostic fails on any channel, signaling a channel fault (not necessarily a module failure).

- Optically Isolated Outputs: This provides electrical isolation between the module’s internal circuitry and the field devices, protecting the module from voltage spikes or ground loops in the field.

- Hot-Spare Capability: The module supports hot-spare capability, meaning a spare module can be inserted and become active online without interrupting the process, significantly reducing downtime for maintenance.

Compatibility and Integration:

The TRICONEX 3604E is designed to work seamlessly within the Triconex ecosystem:

- Triconex Chassis Integration: It plugs into a Triconex I/O chassis (like the Triconex 8111 expansion chassis discussed previously).

- External Termination Panel (ETP): It requires a separate ETP (Field Termination Assembly – FTA) for field wiring, which connects to the module via a cable interface. The ETP contains the fuses for each output point.

Technical Specifications:

Applications:

The TRICONEX 3604E is deployed in the most demanding and safety-critical industrial applications across various sectors:

- Oil & Gas (Upstream, Midstream, Downstream):

- Emergency Shutdown Systems (ESD): Actuating valves, pumps, and other devices to bring a process to a safe state during emergencies.

- Fire & Gas (F&G) Systems: Activating alarms, deluge systems, and ventilation in response to fire or gas detection.

- Wellhead Control: Safe control of drilling and production operations.

- Petrochemical and Chemical Plants:

- Protecting reactors, furnaces, and other hazardous process equipment.

- Managing critical interlocks and safety shutdowns.

- Power Generation (Fossil Fuel and Nuclear):

- Burner Management Systems (BMS): Ensuring safe startup, operation, and shutdown of boiler burners.

- Turbine Overspeed Protection.

- Reactor Safety Systems.

- Water and Wastewater Treatment:

- Safety interlocks for chemical dosing, pump control, and emergency ventilation.

- Pharmaceutical Manufacturing:

- Ensuring safe and precise control of critical process steps and cleanroom environments.

- Pulp and Paper:

- Safety shutdowns for pulp digesters, paper machines, and power recovery boilers.

Related Products:

The TRICONEX 3604E operates within a larger safety system architecture. Here are some related components and systems:

- Triconex Controllers (e.g., Tricon v9, Tricon CX): These are the main CPUs that issue the output commands to the 3604E module.

- Triconex Digital Input Modules (e.g., 3501E, 3502E): These are the counterparts to DO modules, used to receive signals from field devices (sensors).

- Triconex Analog Input/Output Modules (e.g., 3700A, 3805E): Used for continuous signal measurement and control.

- Triconex 8111 Expansion Chassis: The physical chassis that houses the 3604E and other I/O modules.

- Triconex External Termination Panels (ETP) / Field Termination Assemblies (FTA): Essential for wiring the 3604E to field devices and typically contain the fuses.

- Schneider Electric EcoStruxure Triconex Safety Systems: The comprehensive suite of hardware and software that the 3604E module is a part of.

- Distributed Control Systems (DCS) / SCADA Systems (e.g., Emerson DeltaV, Honeywell Experion PKS, ABB Ability System 800xA): While the Triconex handles the critical safety layer, these systems often monitor the status of the Triconex system and can receive safety-related information (e.g., alarms) through communication modules that might be in the same chassis as the 3604E.

- Actuators (e.g., Solenoid Valves, Motor Starters): These are the field devices that the 3604E module directly controls.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922