الوصف

Product Name

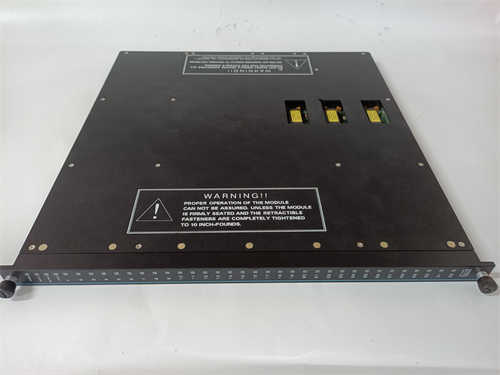

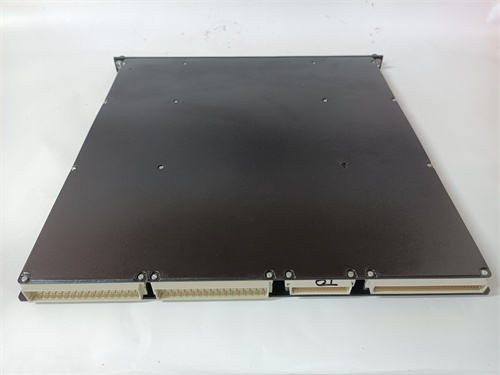

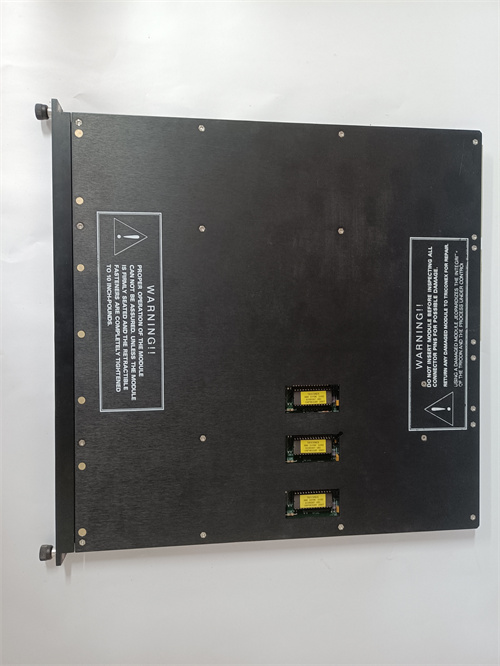

TRICONEX 3664

Product Description

TRICONEX 3664 is a highly reliable and versatile programmable logic controller (PLC) that is part of the Tricon series designed for safety and critical process applications. Known for its robust architecture, the TRICONEX 3664 system offers exceptional performance in managing complex automation tasks. The controller is built to provide real-time data processing, ensuring that operations run smoothly and interruptions are minimized. With the TRICONEX 3664, users benefit from a system that is capable of handling various inputs and outputs, making it suitable for a wide range of industrial applications.

The TRICONEX 3664 features advanced functionalities, including dual redundant processors, which enhance its fault tolerance and reliability. This PLC’s modular design allows for easy expansion and integration into existing systems, making it a preferred choice for industries that demand high availability and safety compliance.

Product Parameters

- TRICONEX+3664

- Power Supply: 24V DC

- Processor Type: Dual redundant processors

- I/O Configuration: Modular, scalable up to 64 I/O points

- Communication Protocols: MODBUS, Ethernet/IP, and proprietary Tricon communications

- Operating Temperature: -20°C to 60°C

- Weight: Approximately 1.5 kg

Advantages and Features

The TRICONEX 3664 offers multiple advantages over traditional PLC systems:

- High Availability: Dual redundant processors ensure that operations continue seamlessly in case of a failure.

- Scalability: Its modular design allows for easy adjustments and expansion as operational needs evolve.

- Safety Compliance: Meets strict safety standards, making it suitable for safety-critical applications.

- Flexible Communication: Supports multiple protocols, providing versatility in integration with other systems.

Application Fields and Case Studies

The TRICONEX 3664 is extensively used across various sectors, including:

- Oil and Gas: For monitoring and controlling various processes, from extraction to refining.

- Chemical Processing: Ensuring safety and efficiency in chemical reaction processes.

- Water Treatment: Managing and controlling water purification systems to maintain regulatory compliance.

- Energy Production: Used in power generation plants to automate process control.

A notable application case includes its deployment in an oil refinery where the TRICONEX 3664 facilitated real-time monitoring and control over complex refining processes, significantly improving operational efficiency and safety.

Competitive Comparison

In comparison to other PLC solutions like Siemens S7 and Allen-Bradley ControlLogix, the TRICONEX 3664 stands out in safety-critical applications due to its high uptime and reliability. While Siemens offers broad functionality, it may not match the rigorous safety standards of the TRICONEX 3664. Meanwhile, Allen-Bradley products may be more user-friendly for certain user bases, yet the advanced fault tolerance and safety features of the TRICONEX 3664 make it the preferable choice for critical industries.

Selection Suggestions

When choosing a PLC for critical applications, consider the following factors:

- Application Environment: Assess the safety requirements and environmental conditions where the PLC will be deployed.

- Scalability Needs: Ensure the PLC can grow with your operational demands.

- Integration Compatibility: Confirm that the communication protocols align with your existing systems.

The TRICONEX 3664 is particularly recommended for applications that prioritize safety and reliability, such as chemical processing and oil and gas industries.

Precautions

While utilizing the TRICONEX 3664, ensure that:

- The installation process follows manufacturer guidelines to avoid operational issues.

- Regular maintenance and updates are carried out to sustain performance.

- Staff is adequately trained to handle the sophisticated functions of the PLC system.

We are your trusted partner for all your automation needs. We provide a wide range of products, including TRICONEX 3664, and other automation spare parts with sales and technical support. Enjoy special discount prices by contacting us. We are here to serve you diligently.

TRICONEX+3664

| S-D4006-D PLC |

| 00-20-4A-C6-FE-1F PLC |

| 0-77-750-0250 PLC |

| 0-77-750-0250B2 PLC |

| 0-77-750-0250D PLC |

| 0-77-750-0251C2 PLC |

| 0-77-750-0251D2 PLC |

| 0-77-75-0250B2 PLC |

| 1005-4-025-012 |

| 20142956/HDSG56-S PLC |

| 2-30/45-30 BUS-003 PLC |

| 2D56K40-2 |

| 2D56K40-2 PLC |

| 3.0121M-S02.01 PLC |

| 3.0123G- S03.10 I/O |

| 3.8109A1 38109A I/O |

| 3.8110A/ 38110A DCS |

| 3.8111D/ 38111D PLC |

| 3.8720AA PLC |

| 3.8934E-38934E PLC |

| 3-10/20-30-002 BUS PLC |

| 38107HA PLC |

| 3BGS3G-35-20-0-003 PLC |

| 623-20/30-54-M-005 BUS PLC |

| 902-04363 PLC |

| 902-35981 PLC |

| BAUMULLER BUR20-30-08-2 I/O |

| BE2/15/300-201000000 PLC |

| BE2/22/300-100 |

| BGS2-3-2220-20100 PLC |

| BGS315-2056L3 PLC |

| BGS3A-10-20-003 PLC |

| BGS3-a-15-20-003 PLC |

| BKD6/30/460-204000010 PLC |

| BKD6/300/460/MX2490 PLC |

| BKD6/400/460-1003 PLCI/O |

| BKD6050460604010009 I/O |

| BKF12/030/400-604000003 PLC |

| BKF12/050/400-2002 PLC |

| BKF12/070/520-604000000 PLC |

| BKF12/100/400-2002 PLC |

| BKF12/100/400-3010001 PLC |

| BKF12/100/400-3010003 I/O |

| BKF12/100/400-3010005 PLC |

| BKF12/100/400-3010101 PLC |

| BKF12/100/400-601000000 PLC |

| HIMA F1101 PLC |

| HIMA F1107 17001 PLC |

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922