الوصف

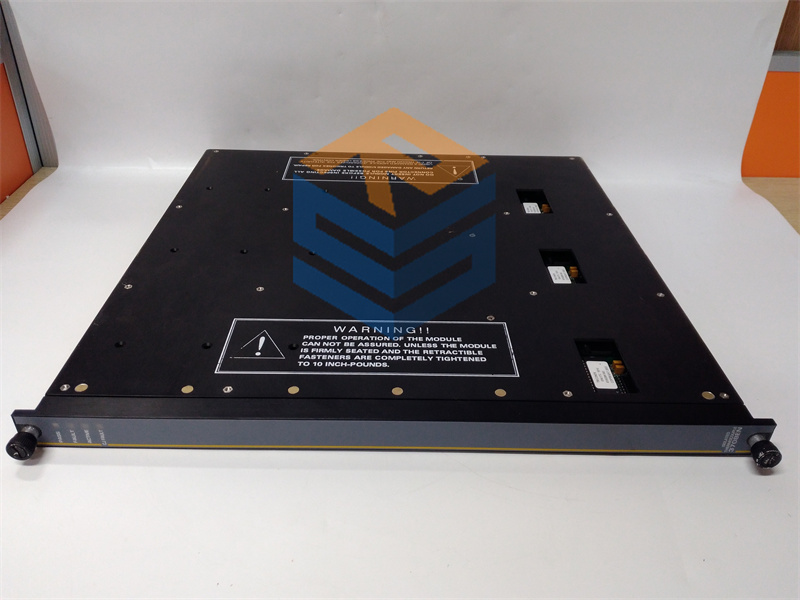

The TRICONEX 3708EN is a Triple Modular Redundant (TMR) Analog Input (AI) Module for the Triconex Safety Instrumented System (SIS). This is a highly robust and critical component used to accurately measure continuous process variables (like temperature, pressure, level, flow) in demanding industrial safety applications.

Its TMR architecture ensures that even if one of its internal components or channels fails, the module continues to provide accurate and reliable input data to the Triconex main processors, making it essential for emergency shutdown (ESD), fire & gas (F&G), and other critical process control applications.

Top 10 SEO-Optimized Headings:

- TRICONEX 3708EN: TMR Analog Input Module for Critical Safety Systems.

- Precision Sensing: Unlock Reliability with the TRICONEX 3708EN in SIS.

- TRICONEX 3708EN: Fault-Tolerant Analog Inputs for Enhanced Process Safety.

- Real-time Data: Leveraging the TRICONEX 3708EN for Critical Monitoring.

- Why Choose TRICONEX 3708EN: Maximizing Uptime in Harsh Industrial Environments.

- TRICONEX 3708EN: The Core of Emergency Shutdown and Fire & Gas Monitoring.

- Hot-Swappable & Self-Diagnosing: Key Features of the TRICONEX 3708EN AI Module.

- TRICONEX 3708EN: Essential for Nuclear Power, Oil & Gas, and Chemical Plant Safety.

- Optimize Your Safety System: The Versatility of the TRICONEX 3708EN Analog Input.

- Industrial Control: Ensuring Integrity with the TRICONEX 3708EN Analog Input Module.

Brief Product Description (for Detail Pages and Search Results):

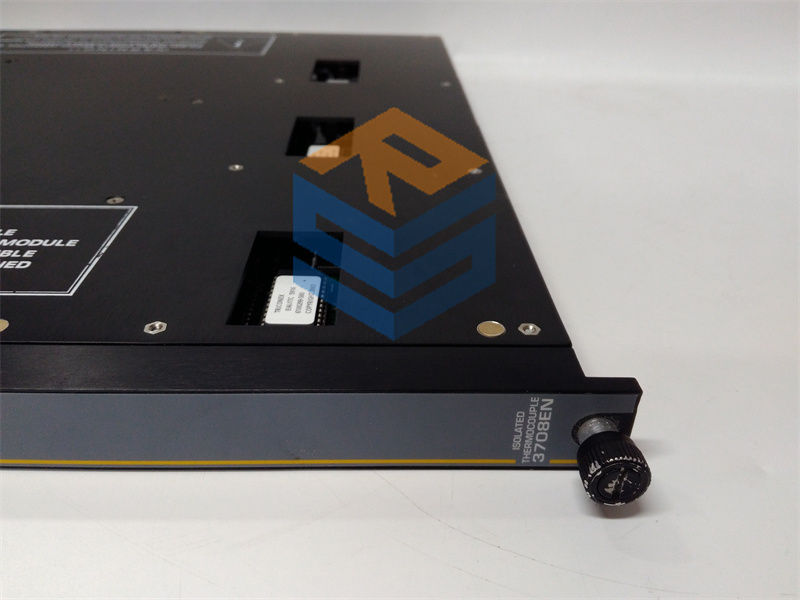

The TRICONEX 3708EN is an 8-channel, Triple Modular Redundant (TMR) Analog Input (AI) module designed for the Triconex Safety Instrumented System (SIS). It provides highly accurate and fault-tolerant measurement of analog signals from process sensors (e.g., 4-20 mA). With its TMR architecture, internal voting mechanisms, and extensive diagnostics, the 3708EN ensures high integrity and availability of critical process data, making it ideal for safety-critical applications such as emergency shutdown, fire & gas detection, and continuous process monitoring.

- Product Type: Analog Input (AI) Module

- Channels: 8 channels

- Signal Type: Typically 4-20 mA, but can support other standard analog signals (e.g., 0-5V, 0-10V, 1-5V).

- Key Feature: Triple Modular Redundancy (TMR), High Accuracy, Isolation.

- Compatibility: Triconex Tricon series controllers (e.g., Tricon v9, Tricon CX). Requires an external termination panel (ETP).

- Applications: Emergency Shutdown (ESD), Fire & Gas (F&G) detection, Process Interlocks, Critical Process Monitoring in industries like Oil & Gas, Petrochemical, Chemical, and Nuclear Power.

Detailed Product Description:

In the intricate world of industrial processes, the ability to accurately and reliably measure continuous variables like temperature and pressure is fundamental, especially when these measurements are tied to safety functions. The TRICONEX 3708EN Analog Input Module is purpose-built for this critical task within a Triconex Safety Instrumented System (SIS). It’s not just a sensor interface; it’s a highly intelligent, fault-tolerant device that ensures the safety system receives unwavering, precise data, even if individual components experience issues. Think of it as the unwavering “eyes” of your safety system, constantly and accurately observing critical process conditions.

From my experience in demanding industrial environments, the integrity of analog inputs is paramount. A faulty temperature reading, for example, could lead to an uncontrolled reaction, or a skewed pressure measurement could prevent a crucial safety valve from activating. The TRICONEX 3708EN directly addresses these concerns. Its TMR architecture, coupled with sophisticated diagnostics, provides an unparalleled level of confidence in the incoming data. This is crucial for preventing hazardous situations and ensuring that safety interlocks and shutdown sequences are initiated based on reliable information.

The Foundation of Reliable Measurement: Triple Modular Redundancy (TMR):

The core principle behind the TRICONEX 3708EN‘s exceptional reliability is its Triple Modular Redundancy (TMR) architecture. Here’s how it ensures data integrity:

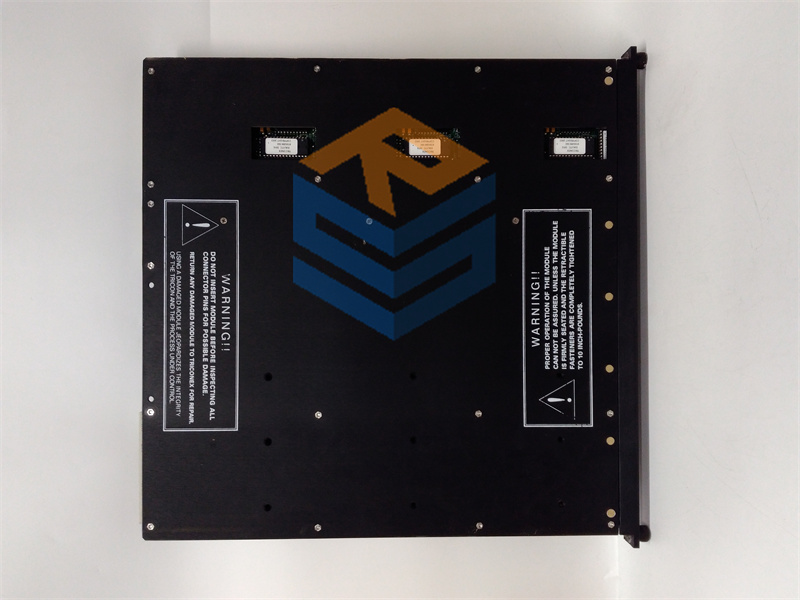

- Three Independent Measurement Channels: Each analog input point is measured by three independent, isolated channels within the module. Each channel has its own dedicated circuitry, including A/D converters.

- Asynchronous Measurement: The three channels asynchronously measure the input signals and place their results into a table of values.

- Hardware Voting: The data from these three channels is then subjected to a robust hardware voting mechanism. This voting process identifies and isolates any discrepancies (e.g., if one channel provides a reading significantly different from the other two).

- Fault Tolerance: This design allows the module to continue providing accurate data even if one of its internal channels fails or provides an erroneous reading. The system will continue to operate reliably in the presence of a single fault, maintaining the integrity of the safety function.

Advanced Diagnostics and Protection:

Beyond TMR, the TRICONEX 3708EN incorporates features designed to enhance its integrity and simplify maintenance:

- Continuous Self-Diagnostics: The module constantly performs extensive self-diagnostics on every channel and critical component. If any diagnostic fails, a “Fault” indicator activates, alerting operators to a channel fault (not necessarily a module failure).

- Open Circuit Detection: Capable of detecting open circuits (e.g., a broken wire) in the field wiring, which is critical for ensuring that sensor signals are continuously reaching the module.

- Hot-Spare Capability: The module supports hot-spare capability. This means a spare module can be inserted into the chassis and become active online without interrupting the process, significantly reducing downtime for maintenance or replacement.

- Electrical Isolation: Provides robust electrical isolation between the field wiring and the module’s internal circuitry, protecting the module from voltage spikes, noise, and ground loops that are common in industrial environments.

- Scalable Redundancy: The module’s design allows for flexible redundancy configurations (e.g., 2oo3 voting for high integrity) within the overall Triconex system.

Compatibility and Integration:

The TRICONEX 3708EN is designed for seamless integration within a Triconex safety system:

- Triconex Chassis Integration: It plugs into a Triconex I/O chassis (like the Triconex 8111 expansion chassis).

- External Termination Panel (ETP): It requires a separate External Termination Panel (ETP) or Field Termination Assembly (FTA) for connecting the field wiring from sensors to the module. This panel also typically provides fuse protection for each input channel.

Technical Specifications (Typical, actual values may vary slightly by revision):

Applications:

The TRICONEX 3708EN is a critical component in the most demanding safety-instrumented systems across various industries:

- Oil & Gas (Upstream, Midstream, Downstream):

- Emergency Shutdown Systems (ESD): Monitoring critical process parameters (pressure, temperature, level) to detect hazardous conditions requiring immediate shutdown.

- Fire & Gas (F&G) Detection Systems: Receiving signals from flame detectors, gas sensors, and heat detectors.

- High-Integrity Pressure Protection Systems (HIPPS): Monitoring pipeline pressures to prevent over-pressurization.

- Petrochemical and Chemical Plants:

- Monitoring reactor temperatures, pressures, and flow rates to prevent runaway reactions or hazardous releases.

- Ensuring safe operation of distillation columns, furnaces, and heat exchangers.

- Power Generation (Fossil Fuel and Nuclear):

- Monitoring boiler drum levels, steam pressures, and turbine speeds for safe operation and protection.

- Reactor protection systems, safety monitoring in balance-of-plant systems.

- Pharmaceutical and Food & Beverage:

- Monitoring critical parameters in batch processes, sterilization cycles, and clean-in-place (CIP) systems to ensure safety and product quality.

- Water and Wastewater Treatment:

- Monitoring tank levels, flow rates, and chemical concentrations for safe and efficient treatment processes.

Related Products:

The TRICONEX 3708EN functions as part of a larger safety system. Here are some related components and systems:

- Triconex Controllers (e.g., Tricon v9, Tricon CX): These are the main CPUs that receive and process the analog input data from the 3708EN.

- Triconex Digital Input/Output Modules (e.g., 3501E, 3604E): Other types of I/O modules that handle discrete (on/off) signals within the same Triconex system.

- Triconex Analog Output Modules (e.g., 3805E): Used to send continuous control signals to analog actuators.

- Triconex 8111 Expansion Chassis: The physical chassis that houses the 3708EN and other I/O modules.

- Triconex External Termination Panels (ETP) / Field Termination Assemblies (FTA): Essential for wiring the 3708EN to field sensors. These panels provide convenient and secure connection points.

- Schneider Electric EcoStruxure Triconex Safety Systems: The comprehensive suite of hardware and software that the 3708EN module is a part of.

- Process Sensors/Transmitters (e.g., Pressure Transmitters, Temperature Transmitters, Flow Meters): These are the field devices that generate the analog signals that the 3708EN module receives and processes.

- Distributed Control Systems (DCS) / SCADA Systems (e.g., Emerson DeltaV, Honeywell Experion PKS, ABB Ability System 800xA): While the Triconex handles the critical safety layer, these systems often monitor the status of the Triconex system and receive safety-related information (e.g., process variable readings for display) through communication modules.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922