الوصف

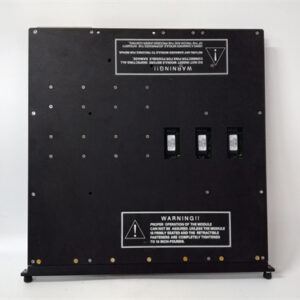

Product Name:

Triconex 4351A DCS/PLC Module

Product Description:

The Triconex 4351A is an I/O module for Triconex safety and control systems, designed to be used within Distributed Control Systems (DCS) and Programmable Logic Controllers (PLC). The 4351A module is part of the Triconex Tricon Safety System, a widely recognized and highly reliable system used in critical safety applications, including industries such as oil & gas, chemical processing, power generation, and petrochemical sectors.

The 4351A module functions as a crucial component in safety-critical environments, where ensuring a safe shutdown or intervention during hazardous situations is vital. It typically supports digital I/O for monitoring and controlling on/off devices, such as valves, sensors, and actuators. The module is known for its high availability, redundancy, and fault tolerance, designed to work in environments where reliability and safety are paramount.

Product Parameters:

- Module Type: Digital Input/Output (I/O) Module for safety systems.

- Input Types: Digital Inputs (Dry contacts, 24V DC signals).

- Output Types: Digital Outputs (Relays, 24V DC signals, or other digital on/off control).

- Communication Protocols: Standard Triconex Communication Protocols.

- Compatibility: Part of the Triconex Safety System, integrates seamlessly with other Triconex modules.

- Redundancy Features: Redundant Power Supplies and Hot Standby configurations available for mission-critical operations.

- Power Supply: Typically operates on 24V DC.

- Mounting: Rack-mounted within a standard Triconex chassis.

Specifications:

1. Input/Output Configuration:

- Digital Inputs:

- Supports a large number of digital input points (e.g., for monitoring on/off devices, emergency shutdown switches, or fire alarm signals).

- 24V DC input signals with isolated contacts (dry contacts), providing electrical isolation between inputs and the module.

- Digital Outputs:

- Supports digital relay outputs for controlling safety-related actuators, valves, and other control devices in emergency shutdown or system safety processes.

- Output relay configurations for controlling circuits based on real-time safety or control logic.

2. Communication Protocols:

- Triconex Communication Protocols: Direct integration with other Triconex safety modules and control systems, ensuring a unified and synchronized safety network.

- Fieldbus Compatibility: Can be part of a broader system with support for Fieldbus and HART-based devices.

3. Processing Capabilities:

- The 4351A module has real-time processing capabilities to monitor and react to field input signals within milliseconds.

- It supports F&G (Fire & Gas) detection logic, enabling safety shutdowns when predefined limits are reached.

- The module also supports diagnostics and self-monitoring features, allowing for proactive fault detection and maintenance.

4. Power Supply:

- Operating voltage: 24V DC, common in industrial control systems.

- The 4351A module supports a redundant power supply configuration for enhanced reliability.

5. Redundancy and Fault Tolerance:

- Redundant configurations (e.g., Hot Standby mode) ensure system reliability in mission-critical environments.

- In the event of a fault, the system is designed to fail safely, with alarms and diagnostics for quick detection of issues.

6. Environmental Specifications:

- Operating Temperature: Typically 0°C to 60°C (32°F to 140°F).

- Storage Temperature: -40°C to 85°C (-40°F to 185°F).

- Humidity: Can operate in environments with 5% to 95% relative humidity (non-condensing).

- Vibration and Shock Resistance: Designed to withstand vibration and shock in industrial environments.

7. Dimensions and Mounting:

- Size: Typically 3U or 6U size for rack-mounted modules.

- Mounting: Rack-mounted within the Triconex chassis or in a dedicated control panel.

8. Safety Features:

- SIL (Safety Integrity Level): The 4351A module is certified for SIL 3 applications, meaning it meets stringent safety standards for highly critical safety functions.

- Fault-tolerant design: Built to detect and handle failures without compromising the safety of the system.

- Real-time diagnostics: Includes features for system health monitoring, providing warnings or alarms in case of module faults.

Applications:

The Triconex 4351A module is used in environments where high safety and reliability are necessary. Some of its key applications include:

- Safety Instrumented Systems (SIS): For monitoring and controlling critical safety functions like emergency shutdowns (ESD), overpressure protection, and fire & gas detection.

- Oil & Gas: In offshore platforms, refineries, and wellhead control, ensuring safety shutdowns and monitoring of hazardous processes.

- Chemical Processing: For monitoring hazardous reactions, controlling exothermic processes, or ensuring emergency shutdowns in case of abnormal conditions.

- Power Generation: Used in control systems for boilers, turbines, and other critical safety applications, protecting against potential hazards.

- Petrochemical Industry: In monitoring and controlling critical equipment such as reactors, distillation columns, and mixers.

- Refining: Ensuring the safe operation of refining units and controlling potentially explosive environments.

Key Features:

- High Reliability and Fault Tolerance: Designed for high-reliability and critical safety applications, with features like redundant power supplies, hot standby, and fault diagnostics.

- Certified for SIL 3: Meets stringent safety requirements for safety-critical systems in industries like oil, gas, and chemicals.

- Real-Time Safety Monitoring: Supports real-time processing and safety logic to ensure safe operation of critical industrial systems.

- Modular Design: Integrates seamlessly with the Triconex system, providing scalability and flexibility.

- Ease of Maintenance: The module has built-in diagnostics, enabling easier troubleshooting and predictive maintenance.

- Compatible with Field Devices: Supports a wide range of fieldbus devices, including HART and standard 4-20mA signals, offering versatility in deployment.

Conclusion:

The Triconex 4351A DCS/PLC Module is a high-performance I/O module specifically designed for safety instrumented systems (SIS) in critical industrial processes. Whether it is for emergency shutdowns, overpressure protection, or other safety-related functions, the 4351A module ensures reliable, real-time control in safety-critical environments. It is an essential component in industries such as oil & gas, chemical processing, power generation, and petrochemical, providing peace of mind with its SIL 3 certification, redundancy, and fault tolerance.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922