الوصف

The TRICONEX 8111 is not a single module, but rather a 19-inch rack-mountable expansion chassis designed for use with Triconex Safety Instrumented System (SIS) applications. It’s a crucial component for expanding the capabilities of a Triconex control system.

Top 10 SEO-Optimized Headings:

- TRICONEX 8111: High-Density Expansion Chassis for Critical Safety Systems.

- Expand Your SIS: Unlock Capacity with the TRICONEX 8111 Chassis.

- TRICONEX 8111: Rugged & Reliable Expansion for Industrial Safety.

- Seamless Integration: The TRICONEX 8111 Chassis for Enhanced I/O and Communication.

- Why Choose TRICONEX 8111: Maximizing Uptime in Harsh Environments.

- TRICONEX 8111: The Core of Scalable and Redundant Safety Systems.

- Hot-Swappable & Redundant: Key Features of the TRICONEX 8111 Expansion Chassis.

- TRICONEX 8111: Essential for Emergency Shutdown and Fire & Gas Systems.

- Optimize Your Triconex System: Leveraging the Power of the 8111 Chassis.

- Industrial Safety Solutions: The Versatility of the TRICONEX 8111 Chassis.

Brief Product Description (for Detail Pages and Search Results):

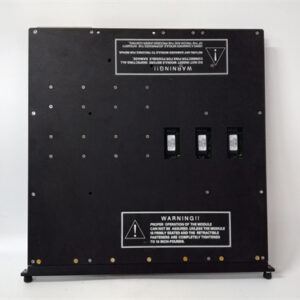

The TRICONEX 8111 is a robust, 19-inch rack-mountable expansion chassis specifically engineered for Triconex Safety Instrumented Systems (SIS). It allows for the integration of additional I/O and communication modules, significantly enhancing system capacity, flexibility, and scalability. Featuring hot-swappable modules and redundant power supplies, the 8111 chassis ensures high reliability, availability, and ease of maintenance in demanding industrial environments. It’s a cornerstone for critical safety applications like emergency shutdown and fire & gas detection.

- Product Type: Expansion Chassis (19-inch rack-mountable)

- Primary Function: Expands I/O and communication module capacity for Triconex SIS.

- Key Features: Triple Modular Redundancy (TMR) support, hot-swappable modules, redundant power supplies.

- Compatibility: Compatible with various Triconex I/O and communication modules and all Triconex controllers (e.g., 4000, 5000, 7000 series).

- Applications: Safety-critical industrial processes, emergency shutdown systems, fire and gas detection systems, nuclear safety systems.

Detailed Product Description:

In the world of industrial automation, particularly within critical safety applications, the ability to expand and enhance a system without compromising its integrity is paramount. This is where the TRICONEX 8111 plays a pivotal role. It’s not a standalone control module, but rather a fundamental building block – a high-density expansion chassis designed to extend the reach and capacity of a Triconex Safety Instrumented System (SIS). Think of it as the foundation upon which you can build a more comprehensive and robust safety infrastructure.

I’ve seen firsthand how companies struggle to scale their safety systems when facing new demands or expanding operations. Without a proper expansion solution, they might resort to complex workarounds or even entirely new systems, which are costly and time-consuming. The TRICONEX 8111 elegantly solves this challenge. It provides the physical and logical framework to add more I/O points and communication capabilities, ensuring your safety system can adapt to evolving industrial needs while maintaining the highest levels of reliability.

The Backbone of System Expansion:

The TRICONEX 8111 chassis serves as a crucial extension for Triconex controllers, enabling the system to manage a greater number of inputs and outputs, as well as integrate additional communication pathways. Here’s what makes it so vital:

- Increased I/O Capacity: It provides additional slots for I/O modules, allowing you to monitor more sensors and control more actuators within your process. This is essential for large or complex industrial facilities that require extensive monitoring for safety.

- Enhanced Communication: The chassis can also house communication modules, facilitating communication between the Triconex system and other control systems (like DCS or SCADA), human-machine interfaces (HMIs), or even remote monitoring stations.

- High-Density Configuration: As a “high-density” chassis, it’s designed to maximize the number of modules it can hold, optimizing cabinet space and system footprint.

Engineered for Reliability and Availability:

The Triconex brand is synonymous with Triple Modular Redundancy (TMR), a core principle for achieving extreme reliability in safety systems. The TRICONEX 8111 chassis is built with this philosophy in mind:

- Redundant Power Supplies: It typically includes two power modules, providing redundancy. This means that if one power supply fails, the system continues to operate seamlessly, preventing downtime in critical applications.

- Hot-Swappable Modules: A key feature for maintaining continuous operation. Modules can be inserted or removed from the chassis while the system is still running, minimizing disruption during maintenance or upgrades.

- Rugged Design: Built to withstand harsh industrial environments, the 8111 chassis ensures durability and operational reliability in challenging conditions, including extreme temperatures, humidity, and vibration.

Seamless Integration and Maintenance:

The TRICONEX 8111 is designed for straightforward installation and maintenance. It integrates directly with the Triconex Main Chassis via the I/O bus, allowing for system expansion within a specified cable length (typically up to 100 feet or 30 meters). Its hot-swappable nature significantly reduces maintenance windows and simplifies troubleshooting.

Technical Specifications:

Applications:

The TRICONEX 8111 chassis is integral to a wide range of safety-critical applications across various industries where operational integrity and human safety are paramount:

- Oil and Gas:

- Emergency Shutdown Systems (ESD): Protecting personnel and assets by safely shutting down processes in the event of an emergency.

- Fire and Gas (F&G) Detection Systems: Rapid detection and response to hazardous conditions.

- Burner Management Systems (BMS): Ensuring safe startup and shutdown of industrial burners.

- Petrochemical and Chemical:

- Preventing runaway reactions and managing hazardous materials.

- Process interlocks and safety shutdowns.

- Power Generation (Traditional and Nuclear):

- Reactor protection systems.

- Turbine control and protection.

- Boiler safety systems.

- Pharmaceutical and Food & Beverage:

- Ensuring safe manufacturing processes and product quality.

- Sterilization and clean-in-place (CIP) safety.

- Water and Wastewater:

- Safety interlocks for pumping stations and treatment processes.

- Monitoring and control of hazardous chemicals.

- Transportation (e.g., Rail, Pipelines):

- Safety systems for signaling, control, and pipeline management.

Related Products:

When considering the TRICONEX 8111, it’s helpful to understand its place within the broader ecosystem of industrial safety and control:

- Triconex Main Chassis (e.g., Tricon MP/Tricon CX controllers): The 8111 directly connects to these main controllers, which house the central processing units (CPUs) of the Triconex SIS.

- Triconex I/O Modules (e.g., Digital Input Modules, Analog Output Modules): These are the actual modules that reside within the 8111 chassis, providing the interface to field devices.

- Triconex Communication Modules (e.g., Ethernet, Serial Modules): Also housed in the 8111, these modules enable various communication protocols.

- Triconex 8121 Enhanced Low-Density Expansion Chassis: Another type of expansion chassis for Triconex systems, sometimes offering different features (e.g., HART communication support).

- Triconex 8112 RXM Chassis: Used for expanding I/O capacity over longer distances (exceeding 100 feet) from the Main Chassis.

- Schneider Electric EcoStruxure Triconex Safety Systems: The overarching platform that incorporates the 8111 chassis and other Triconex components.

- Distributed Control Systems (DCS) / Supervisory Control and Data Acquisition (SCADA) Systems: While Triconex handles safety, these systems often communicate with the Triconex SIS (via modules in the 8111) for overall process control and monitoring. Examples include Emerson DeltaV, Honeywell Experion PKS, and ABB Ability System 800xA.

- Programmable Logic Controllers (PLCs) (e.g., Siemens SIMATIC S7, Rockwell Allen-Bradley ControlLogix): While PLCs can handle control, safety PLCs or dedicated SIS like Triconex are used for critical safety functions. Communication between PLCs and Triconex may occur through modules in the 8111 chassis.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922