الوصف

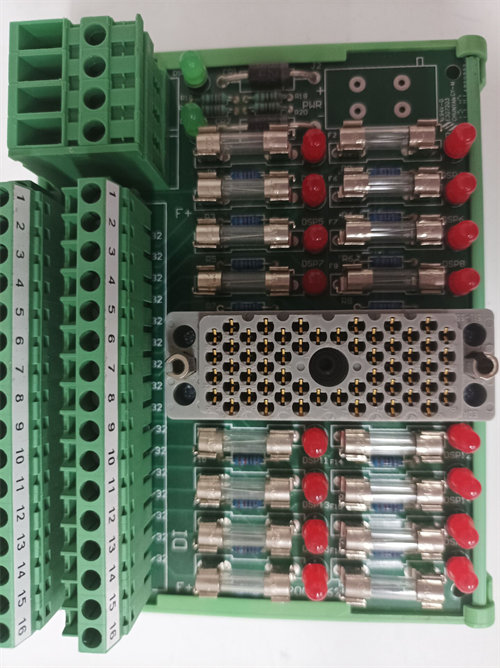

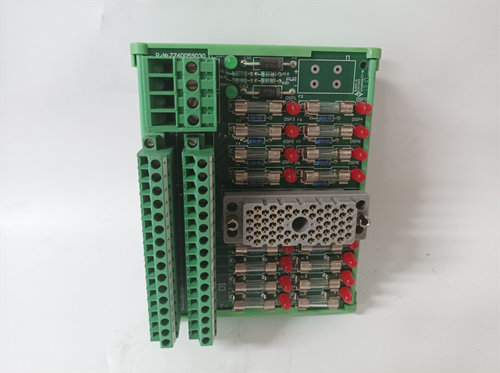

TRICONEX 9563-810 DCS/PLC Module

Product Name:

TRICONEX 9563-810 DCS/PLC Module

Product Description:

The TRICONEX 9563-810 is a high-performance Distributed Control System (DCS) / Programmable Logic Controller (PLC) module designed for safety-critical and mission-critical applications in industries such as oil and gas, chemical processing, power generation, and manufacturing automation. Manufactured by Emerson under the Triconex brand, this module is part of the Tricon series of safety systems. It is specifically engineered to meet the requirements of complex control and safety functions, while providing high reliability, fault tolerance, and advanced diagnostics.

The 9563-810 module is ideal for process automation and safety instrumented systems (SIS) that require redundant architectures, high availability, and continuous operation. It integrates seamlessly with other Triconex components, providing enhanced control of processes where downtime can be costly and unsafe. With support for SIL 3 (Safety Integrity Level 3), it is well-suited for safety-critical environments where compliance with stringent safety standards is mandatory.

Key Features:

-

Safety Integrity:

- SIL 3 certified, designed for use in safety instrumented systems (SIS), ensuring high levels of reliability and safety.

-

Fault-Tolerant Architecture:

- Redundant processors, power supplies, and communication paths to ensure continuous operation and minimize downtime.

-

Advanced Diagnostics:

- Provides real-time monitoring and advanced diagnostics to detect faults early, ensuring quick troubleshooting and high system uptime.

-

High Availability:

- Designed for 24/7 operations, with built-in redundancies to maintain system availability even during maintenance or component failures.

-

Wide Application Range:

- Suitable for a variety of process control, safety and automation applications in industries like oil & gas, chemical, power, and water treatment.

-

Modular Design:

- The modular architecture allows for flexible system expansion and easy integration with other Triconex devices and third-party systems.

-

Communication Protocols:

- Supports multiple industrial communication protocols, including Modbus, Ethernet/IP, and Profinet, to integrate with existing control systems and ensure seamless data exchange.

-

Real-Time Control:

- Capable of performing complex control and decision-making tasks in real-time, ensuring quick response to process changes and disturbances.

-

User-Friendly Configuration:

- Easily configured with Triconex’s proprietary software tools, including Tricon Control and Tricon Safety, for simplified setup and management.

Product Parameters and Specifications:

General Specifications:

- Product Name: TRICONEX 9563-810

- Series: Tricon

- Type: DCS/PLC Module

- Manufacturer: Emerson (Triconex)

- Function: Process Control, Safety Instrumented Systems (SIS), Automation

Electrical Specifications:

- Input Voltage:

- 24V DC (nominal); typically operates between 20V DC to 28V DC.

- Power Consumption:

- Typically between 10W to 30W, depending on the configuration.

- Operating Temperature:

- 0°C to +60°C (32°F to 140°F).

- Storage Temperature:

- -20°C to +70°C (-4°F to 158°F).

- Humidity:

- 5% to 95% non-condensing.

I/O Configuration:

- Digital I/O:

- Supports discrete input and output signals for controlling devices such as relays, switches, and alarms.

- Analog I/O:

- Capable of 4-20mA and 0-10V analog inputs/outputs for precise process control.

- Relay Outputs:

- Includes relay outputs for controlling external devices like actuators, alarms, or external control systems.

Communication and Networking:

- Ethernet/IP:

- Supports Ethernet/IP for high-speed communication and integration with other industrial control systems.

- Modbus:

- Fully supports Modbus RTU and Modbus TCP/IP for external communication with other field devices and systems.

- Profinet:

- Supports Profinet communication for seamless integration with PROFINET-based systems.

- Redundant Communication:

- Provides redundant network connections for high availability and continuous operation.

Safety and Compliance:

- Safety Integrity:

- Designed and certified to meet SIL 3 safety standards for safety instrumented systems.

- EMC Compliance:

- Compliant with EMC (Electromagnetic Compatibility) standards for reliable operation in environments with high levels of electrical noise.

- Safety Standards Compliance:

- Meets industry standards such as IEC 61508, IEC 61511, and ISO 13849 for functional safety and operational integrity.

Software and Programming:

- Software Compatibility:

- Compatible with Triconex proprietary software such as Tricon Control and Tricon Safety for configuration, programming, and diagnostics.

- Programming Languages:

- Supports various programming languages including Ladder Logic, Function Block Diagram (FBD), and Structured Text (ST) for flexible programming options.

- Configuration Tools:

- Utilizes Triconex Configuration Tools for setting up I/O, parameters, and system settings for ease of use.

- User Interface:

- Integrated with Triconex HMI/SCADA systems for real-time monitoring and system diagnostics.

Maintenance and Diagnostics:

- Integrated Diagnostics:

- Provides real-time system diagnostics and fault detection to identify and isolate issues quickly, ensuring minimized downtime.

- Event Logging:

- Capable of logging critical operational events, such as errors, system faults, and maintenance alerts, to support proactive maintenance.

- Predictive Maintenance:

- Supports predictive maintenance strategies through diagnostics, allowing operators to anticipate potential failures before they occur.

Applications:

-

Oil & Gas:

- Ideal for oil rigs, refineries, and pipeline monitoring, ensuring safe and efficient operations in hazardous environments.

-

Chemical Processing:

- Used in chemical plants to automate processes, manage reactions, monitor pressure/temperature, and ensure compliance with safety standards.

-

Power Generation:

- Controls and monitors systems in power plants, ensuring safe operation of turbines, generators, and auxiliary systems.

-

Water & Wastewater Treatment:

- Perfect for managing processes such as filtration, chemical dosing, and flow control in water treatment facilities.

-

Manufacturing Automation:

- Controls robotic systems, production lines, and material handling systems in manufacturing plants.

Conclusion:

The TRICONEX 9563-810 DCS/PLC Module is a robust and reliable solution for safety-critical and high-performance automation applications. With its SIL 3 certification, redundant architecture, and advanced diagnostics, this module is perfect for industries such as oil & gas, chemical processing, power generation, and water treatment. The flexibility of communication protocols, real-time control capabilities, and easy integration with other Triconex systems make it a top choice for complex and demanding control and safety requirements.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922