الوصف

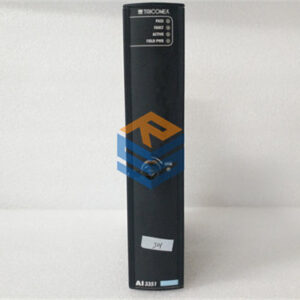

Product Name:

TRICONEX+9771-210 DCS PLC Module

Product Description:

The TRICONEX+9771-210 is a high-performance Distributed Control System (DCS) PLC Module from Triconex, a leading provider of safety, control, and automation solutions. This module is designed to support the Tricon system, which is widely used in critical industrial processes that demand high availability, redundancy, and real-time control. The 9771-210 model is optimized for applications in industries like oil and gas, chemical processing, power generation, and pharmaceuticals.

Triconex’s 9771-210 module offers exceptional reliability, scalability, and safety features, ensuring that your system can maintain operational continuity in even the most challenging environments. It integrates seamlessly into Tricon safety and control systems, offering redundancy at every level to ensure safety and system integrity. This DCS PLC module is designed to meet the highest standards of process control, providing features such as fault tolerance, redundant processing, and real-time monitoring.

Product Parameters & Specifications:

General Specifications:

- Model: TRICONEX+9771-210

- Type: DCS (Distributed Control System) PLC Module

- Manufacturer: Triconex

- System Compatibility: Tricon System

- Primary Use: Industrial process control and automation in critical applications

- Industry Applications: Oil & Gas, Chemical Processing, Power Generation, Pharmaceuticals, Utilities

Key Features:

-

Fault-Tolerant Design: The 9771-210 module supports dual-redundant processors and power supplies, ensuring that system failure is minimized and critical processes remain operational even during component failures.

-

Real-Time Monitoring & Diagnostics: The module is equipped with advanced diagnostics and real-time monitoring capabilities, allowing operators to quickly identify issues, predict failures, and perform preventative maintenance to minimize downtime.

-

Modular & Scalable: The 9771-210 is a modular system that allows you to scale your DCS configuration based on your specific operational needs. The flexibility of the I/O module design enables efficient expansion as system demands grow.

-

Safety Integrity: As part of the Triconex Safety System, this module adheres to the highest safety integrity levels, providing SIL 3 (Safety Integrity Level 3) rated solutions for applications requiring high reliability and safety.

-

Real-Time Control: The module supports high-speed I/O and real-time control to execute critical control loops, enabling precise adjustments to operational processes with minimal delay.

-

Redundant Communication: It includes multiple communication paths, ensuring uninterrupted data transmission and control, even in the case of network failures.

Electrical Specifications:

-

Power Supply:

- 24V DC power supply input.

- Redundant power supply option for increased system reliability and fault tolerance.

-

Power Consumption:

- Typical power consumption depends on the configuration of I/O modules and system setup.

-

Communication Protocols:

- Supports various industrial communication protocols such as Modbus, Ethernet/IP, and RS-485 for easy integration into other control systems and networks.

Mechanical Specifications:

-

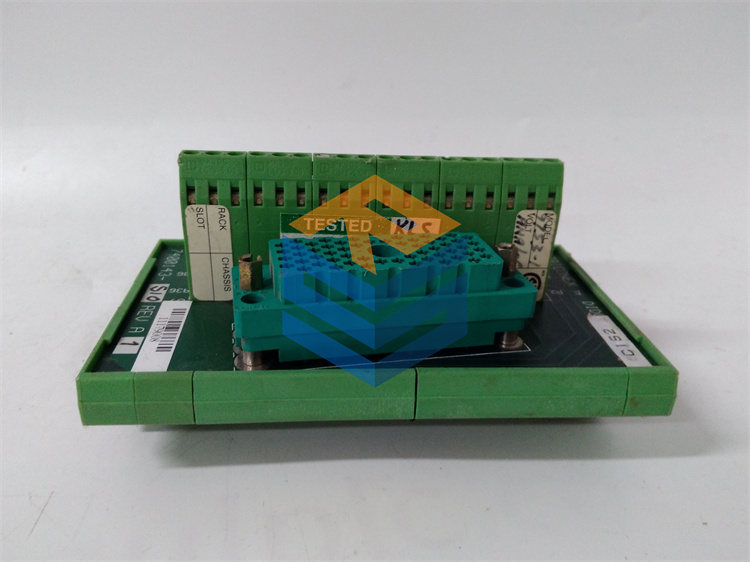

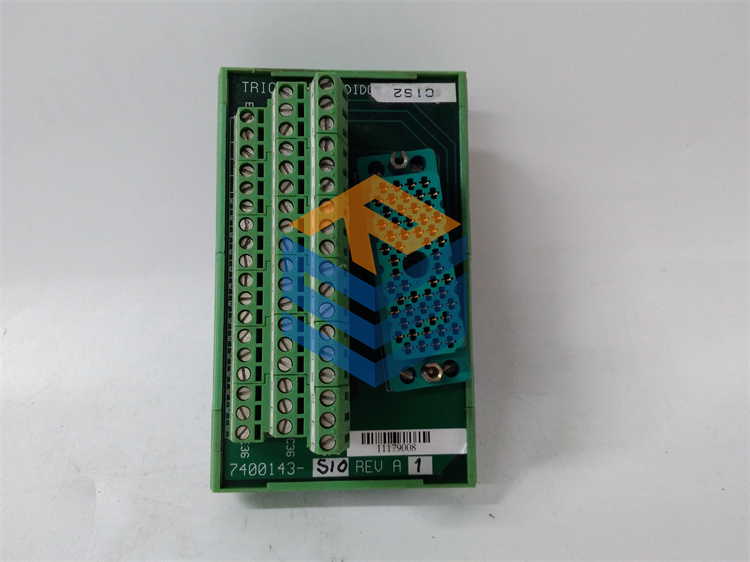

Form Factor:

- The module is typically designed for rack-mount installation in a 19-inch rack.

-

Dimensions:

- Height: 3U (standard rack unit).

- Depth and width vary based on configuration.

-

Weight:

- Approximately 2.5 – 4 kg, depending on configuration and setup.

-

Cooling:

- The module requires adequate airflow for passive cooling; active cooling may be necessary for high-temperature environments.

Environmental Specifications:

-

Operating Temperature:

- Typically rated between -20°C to +60°C, suitable for a wide range of industrial environments.

-

Storage Temperature:

- -40°C to +85°C for safe shipping and storage.

-

Relative Humidity:

- The module operates effectively within 5% to 95% non-condensing relative humidity.

-

Vibration and Shock Resistance:

- Designed to withstand industrial-level vibration and shock conditions, ensuring durability in dynamic environments.

-

Ingress Protection:

- Typically rated IP20, which provides protection against dust and accidental contact, but additional enclosures may be required for extreme environments.

Functional Specifications:

-

I/O Support:

- The 9771-210 supports a wide range of digital and analog I/O modules, making it highly flexible for a variety of control applications.

- Ideal for high-speed control loops as well as low-speed monitoring and control.

-

Redundant Processors:

- The module uses dual-redundant processors that can seamlessly switch between each other in case of a failure, ensuring high availability.

-

Safety Features:

- The system provides SIL 3 safety capabilities, allowing the module to be used in environments where safety is critical, such as chemical plants or oil refineries.

-

Event Logging & Diagnostics:

- Features advanced event logging capabilities, providing a detailed history of system events, faults, and operator actions for troubleshooting and compliance audits.

-

Control and Automation:

- Facilitates PID control, sequence control, and feedback loop regulation, which are essential for industrial process control tasks.

-

Redundant Communication:

- Provides redundant communication paths, ensuring continuous data flow between controllers and I/O modules, reducing the risk of data loss.

Software & Configuration:

- Configuration Software:

- The Triconex System is configured and maintained using Tricon Configurator or Tricon Studio, which allows for seamless programming and system setup.

- Diagnostic Tools:

- Includes integrated diagnostic tools for system health monitoring, performance evaluation, and predictive maintenance.

Applications:

-

Oil & Gas:

- Widely used in drilling, refining, and pipeline monitoring for critical process control and safety.

-

Chemical & Petrochemical:

- Supports high-reliability applications in chemical reactors, blending systems, and critical safety monitoring.

-

Power Generation:

- Ensures optimal control and protection for power plants, including boiler control, turbine regulation, and generator synchronization.

-

Pharmaceutical:

- Used in pharmaceutical production processes that require precise control and real-time safety features.

-

Utilities:

- Ideal for water treatment, waste management, and other utility control systems requiring safety and reliability.

This module represents an optimal solution for industrial automation, offering redundancy, scalability, high availability, and safety.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922