الوصف

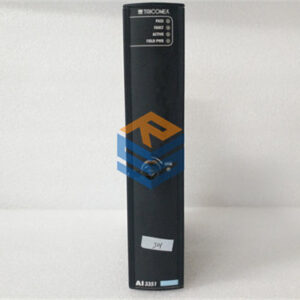

The TRICONEX CM2201 7400206-100 is a Communication Module Baseplate for the Triconex Safety Instrumented System (SIS). While “CM2201” is the model number, “7400206-100” is its specific part number.

This module baseplate is a crucial component that facilitates various communication protocols, allowing the Triconex safety PLC to integrate seamlessly with other control systems, human-machine interfaces (HMIs), and network devices. It plays a vital role in ensuring data exchange, remote monitoring, and overall system visibility in critical industrial environments.

Top 10 SEO-Optimized Headings:

- TRICONEX CM2201 7400206-100: Communication Module Baseplate for SIS.

- Seamless Integration: Unlock Connectivity with the TRICONEX CM2201.

- TRICONEX CM2201: Fault-Tolerant Communication for Critical Safety Systems.

- Network Your Safety: Leveraging the TRICONEX CM2201 7400206-100.

- Why Choose TRICONEX CM2201: Robust Data Exchange in Hazardous Environments.

- TRICONEX CM2201 7400206-100: The Gateway for Remote Monitoring & Control.

- Flexible Protocols: Key Features of the TRICONEX CM2201 Baseplate.

- TRICONEX CM2201: Essential for Oil & Gas, Power Generation, and Chemical Safety.

- Optimize Your SIS: The Versatility of the TRICONEX CM2201 7400206-100.

- Industrial Communication: Ensuring Integrity with the TRICONEX CM2201.

Brief Product Description (for Detail Pages and Search Results):

The TRICONEX CM2201 7400206-100 is a communication module baseplate designed for Triconex Safety Instrumented Systems (SIS). This module provides the physical and logical interface for the Triconex controller to communicate with external systems using various industrial protocols like Modbus, OPC, and Ethernet/IP. It supports remote monitoring, configuration, and data exchange, enhancing the overall functionality and integration of the safety system in critical applications across industries such as oil & gas, power generation, and chemical processing. Its robust design is engineered to meet stringent industry standards for hazardous locations and continuous operation.

- Product Type: Communication Module Baseplate

- Model Number: CM2201

- Part Number: 7400206-100

- Primary Function: Facilitates communication between Triconex Safety PLC and external systems.

- Supported Protocols (Typical): Modbus, OPC, Ethernet/IP (may support others based on configuration).

- Key Features: Designed for high reliability, fault tolerance, supports Triple Modular Redundancy (TMR) of the associated Triconex controller.

- Compatibility: Triconex Tricon series safety controllers.

- Applications: Integration with DCS/SCADA, HMIs, data historians for monitoring and control in safety-critical industrial processes.

Detailed Product Description:

In modern industrial facilities, the ability of different control systems to communicate seamlessly is fundamental to efficient and safe operations. When it comes to safety-instrumented systems (SIS), this communication is not just about convenience; it’s about providing the critical data needed for informed decision-making and ensuring the integrity of the safety functions. This is precisely the role of the TRICONEX CM2201 7400206-100. It’s not a processing unit itself, but rather the essential foundation that enables the Triconex safety PLC to “speak” to the outside world, bringing vital information to operators and other systems.

I’ve observed many complex industrial setups where integrating safety systems with the plant’s overall control network can be a significant challenge. Without a reliable communication interface like the TRICONEX CM2201, safety data could remain isolated, preventing proactive monitoring or delaying critical responses. This baseplate acts as a bridge, ensuring that the highly reliable data generated by the Triconex system—such as diagnostics, alarms, and process statuses—is readily available to operators and higher-level control systems. This connectivity enhances overall situational awareness and supports faster, more effective responses to potential safety incidents.

The Connectivity Hub for Safety Systems:

The TRICONEX CM2201 7400206-100 communication module baseplate serves as the primary interface for enabling data exchange between the Triconex controller and various external systems. Its key functions include:

- Protocol Support: It supports a range of industry-standard communication protocols, including:

- Modbus (RTU/TCP): A very common serial and Ethernet protocol for industrial automation, allowing Triconex to exchange data with PLCs, DCS, and RTUs.

- OPC (OLE for Process Control): A widely used standard for data exchange between industrial control applications and OPC clients (e.g., HMIs, historians, SCADA systems).

- Ethernet/IP: A modern industrial Ethernet protocol for real-time control and information exchange.

- Other Protocols: Depending on the specific configuration or modules that plug into this baseplate, it may support additional proprietary or industry-specific protocols.

- Data Exchange: It allows for the transmission of critical information from the Triconex system, such as:

- System status and health

- I/O module status

- Alarm conditions and event logs

- Process variable values (from input modules)

- Diagnostic information

- Remote Monitoring and Configuration: By enabling network connectivity, the CM2201 supports remote monitoring of the safety system’s operational status and can facilitate remote configuration or programming (where permitted and secure).

Engineered for Critical Environments:

As part of the Triconex family, the CM2201 baseplate is designed to meet the rigorous demands of safety-critical applications:

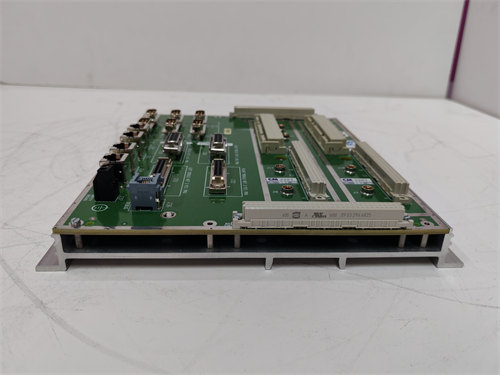

- High Reliability and Fault Tolerance: While the baseplate itself doesn’t offer TMR, it is designed to work seamlessly with Triconex TMR controllers, ensuring that the communication pathway complements the system’s overall fault tolerance. It’s built to withstand the operational stresses of continuous industrial environments.

- Hazardous Location Ratings: It is rated for use in hazardous locations (e.g., Class I, Division 2, Groups A, B, C, and D), making it suitable for deployment in challenging industrial sites like oil refineries and chemical plants.

- Robust Construction: Built to industrial standards to ensure durability and operational reliability in environments with varying temperatures (-40°C to +70°C), humidity, and potential vibration.

Seamless Integration and Maintenance:

The CM2201 is designed for straightforward physical and logical integration within the Triconex system:

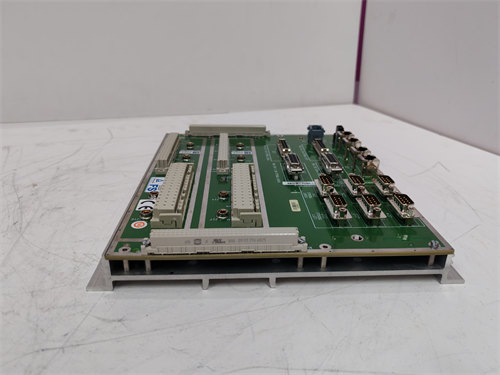

- Modular Design: It serves as a baseplate, meaning specific communication interface modules (which might be separate sub-modules) would plug into it, offering flexibility in communication options.

- Ease of Installation: It is typically rack-mountable, designed for easy installation within standard industrial enclosures.

- Simplified Troubleshooting: While not a “diagnostic module” itself, its role in facilitating communication means that if there are communication issues, troubleshooting often begins here.

Technical Specifications (Typical, as a baseplate, specific communication capabilities depend on modules plugged in):

Applications:

The TRICONEX CM2201 7400206-100 is indispensable in a wide array of safety-critical industrial applications where data exchange and remote connectivity are essential for both safety and operational efficiency:

- Oil & Gas (Refineries, Offshore Platforms, Pipelines):

- Integrating ESD and F&G systems with plant-wide DCS/SCADA for comprehensive process monitoring and control.

- Transmitting alarm and event data to control room operators and data historians.

- Petrochemical and Chemical Plants:

- Enabling communication between safety interlock systems and process control systems to prevent hazardous incidents and optimize production.

- Providing remote access for system diagnostics and health monitoring.

- Power Generation (Fossil Fuel, Nuclear, Renewables):

- Connecting burner management systems and turbine protection systems to the main plant control system.

- Facilitating data logging for compliance and performance analysis.

- Water and Wastewater Treatment:

- Enabling real-time monitoring of safety parameters and alarm conditions from remote pumping stations and treatment facilities.

- Pharmaceutical Manufacturing:

- Ensuring traceability and compliance by transmitting safety system data to quality management systems.

- Mining:

- Providing remote access to safety systems in hazardous or remote mining environments for monitoring and emergency response.

Related Products:

The TRICONEX CM2201 7400206-100 works in conjunction with other components within the Triconex ecosystem and interfaces with external systems:

- Triconex Controllers (e.g., Tricon v9, Tricon CX): The main safety programmable logic controllers that utilize this communication module baseplate for external connectivity.

- Triconex I/O Modules (e.g., Digital Input, Analog Output, etc.): The CM2201 facilitates the communication of data from these I/O modules to external systems.

- Triconex 8111 Expansion Chassis: The physical chassis that houses the Triconex modules, including potentially communication modules that would sit on the CM2201 baseplate.

- Triconex Communication Modules (e.g., 4351, 4119): Specific communication interface cards that plug into the CM2201 baseplate to provide the various protocol capabilities (e.g., Modbus, Ethernet).

- Distributed Control Systems (DCS) (e.g., Emerson DeltaV, Honeywell Experion PKS, ABB Ability System 800xA): These are the higher-level control systems that often communicate with the Triconex SIS via the CM2201 to receive safety-related data and status.

- SCADA Systems: Supervisory Control and Data Acquisition systems that rely on communication modules like the CM2201 for data acquisition from remote or distributed safety systems.

- Human Machine Interfaces (HMIs): Operator interfaces that display real-time data and alarms communicated via the CM2201.

- Industrial Ethernet Switches/Networks: If using Ethernet/IP, the CM2201 would connect to industrial Ethernet infrastructure.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922