الوصف

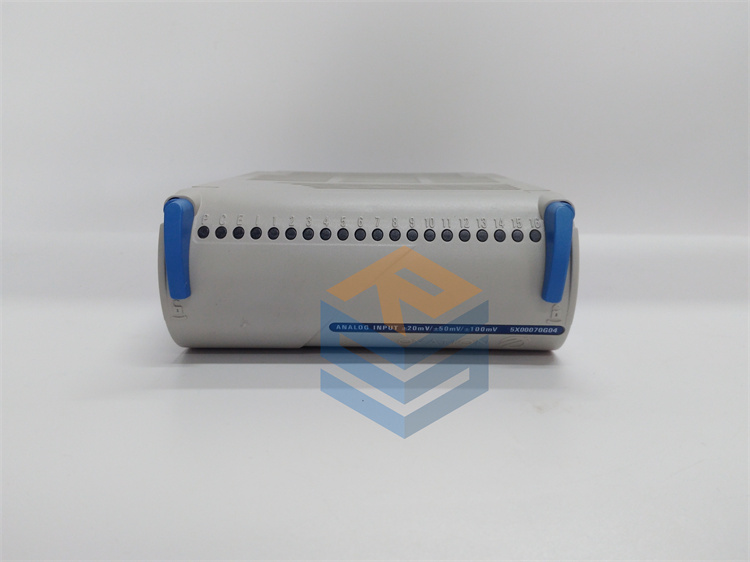

WESTINGHOUSE 5X00070G04 DCS PLC Module

Product Name:

WESTINGHOUSE 5X00070G04 – DCS PLC Module

Product Description:

The WESTINGHOUSE 5X00070G04 is a high-performance DCS (Distributed Control System) PLC Module designed for integration into industrial automation systems. Developed by Westinghouse Electric, a leader in industrial automation, the 5X00070G04 module is engineered to deliver reliable, scalable, and efficient control solutions for critical infrastructure applications. It is optimized for complex process control in industries such as power generation, petrochemical, water treatment, and manufacturing.

The 5X00070G04 is built for applications where system uptime, safety, and real-time performance are paramount. The module features advanced control algorithms, high-speed communication capabilities, and comprehensive diagnostics, ensuring minimal downtime and optimal system performance. This module is widely used in distributed control systems (DCS) for both large-scale process industries and smaller, specialized automation environments.

Product Parameters:

- Model: WESTINGHOUSE 5X00070G04

- Type: DCS PLC Module

- System Compatibility: Compatible with Westinghouse DCS platforms (e.g., WESTINGHOUSE Ovation™, WDPF™ systems).

- Power Supply:

- Input: 24V DC

- Power consumption: ~20W to 40W (varies with configuration)

- Dimensions:

- Approx. 7.5″ x 12″ x 2″ (specific measurements may vary based on rack configuration).

- Weight: Approx. 1.5 kg

- Operating Temperature:

- 0°C to 60°C (Ambient temperature range)

- Storage: -40°C to 85°C

- Relative Humidity: 5% to 95%, non-condensing

Key Specifications:

-

Processor:

- High-performance processor optimized for real-time control and process monitoring.

- Multi-core architecture for handling complex control tasks simultaneously.

- Low-latency response for mission-critical processes.

-

Memory:

- RAM: 512MB to 1GB (depending on configuration).

- Flash Memory: 2GB to 4GB for storing configuration files, system logs, and control programs.

- Expandable Memory: Supports external memory expansion to handle large control applications.

-

Communication Protocols:

- Ethernet/IP: Supports high-speed Ethernet communication for seamless system integration.

- Modbus TCP/IP: Allows integration with legacy equipment and systems.

- PROFIBUS/PROFINET: Flexible fieldbus support for industrial devices and controllers.

- OPC (OLE for Process Control): Supports industrial automation standards for communication between devices.

- Redundant Communication: Includes redundant network paths to ensure communication reliability in high-availability environments.

- Serial Communication: Includes support for RS232/RS485 for legacy communication systems.

-

I/O Capability:

- Digital I/O: Configurable up to 32 digital inputs and outputs per module (depending on system design).

- Analog I/O: Configurable up to 16 analog inputs and 8 analog outputs per module.

- Fieldbus I/O: Provides integration with fieldbus networks like HART, Foundation Fieldbus, and others, enabling scalability and device connectivity.

- Expandable I/O: The module allows for easy expansion by adding additional I/O modules as required.

-

Control Functions:

- Real-Time Control: Supports real-time execution of control algorithms such as PID, adaptive control, and set-point control.

- Distributed Control: Works within a distributed architecture to perform control tasks over wide-ranging systems.

- Redundant Control: Allows redundancy of both hardware and software to enhance system reliability in critical applications.

- Advanced Control Algorithms: Supports complex control strategies for dynamic process optimization and system performance enhancement.

-

Safety Features:

- SIL 2/3 Compliance: Certified for Safety Integrity Levels (SIL 2/3) for safety-critical applications such as power generation and chemical processing.

- Emergency Shutdown (ESD): Integration into safety systems to perform emergency shutdown procedures in response to hazardous conditions.

- Fail-Safe Operation: Ensures safe operation during component or system failures, providing continuous monitoring and fallback procedures.

-

Diagnostics and Monitoring:

- Self-Diagnostics: Built-in diagnostic routines to detect faults early and minimize system downtime.

- Status Monitoring: Continuous monitoring of I/O status, communication integrity, and process variables.

- Alarm Management: Advanced alarm management to prioritize critical issues and provide real-time alerts.

- Event Logging: Detailed event logging of system faults, warning signs, and user-defined events for future analysis and troubleshooting.

-

User Interface:

- Integrated with WESTINGHOUSE Control Systems: The module integrates directly with Westinghouse’s control software platforms such as Ovation™ for ease of configuration, control, and diagnostics.

- Remote Access: Supports web-based interfaces for remote monitoring and system management.

- Human-Machine Interface (HMI): Graphical HMI support for easy user interaction with control and diagnostic information.

Key Features and Advantages:

-

Scalable Architecture:

The 5X00070G04 module is part of a modular DCS system that can easily scale according to system complexity. Additional I/O, processing modules, and control units can be added as needed. -

High-Performance and Real-Time Control:

The module is optimized for high-speed, real-time control of critical industrial processes, ensuring accurate and timely system response in high-demand environments. -

Safety Compliance:

With SIL 2/3 certification, the 5X00070G04 ensures compliance with international safety standards, making it ideal for use in applications that require high safety levels, such as power plants, chemical processes, and oil & gas industries. -

Advanced Diagnostic Capabilities:

The module comes equipped with advanced diagnostics, predictive maintenance features, and fault-tolerant operation, reducing the risk of unplanned downtime. -

Redundancy for High Availability:

The 5X00070G04 supports redundant configurations for both hardware and communication paths, ensuring continued operation even in the event of a failure. -

Flexible Communication and Integration:

The module supports a wide range of communication protocols (Ethernet/IP, Modbus, PROFIBUS, OPC, etc.), enabling easy integration into existing automation systems. -

Compact and Robust Design:

The 5X00070G04 is designed for space-constrained environments while maintaining robust functionality. It can operate in a wide range of industrial conditions, making it suitable for tough environments. -

Enhanced Performance with Modular Expandability:

The DCS PLC system is designed to handle increasing complexity by adding modules for additional I/O or processing power as the system grows.

Applications:

The WESTINGHOUSE 5X00070G04 is ideal for industries where high reliability, real-time control, and safety are critical:

- Power Generation: Integration in nuclear, coal, gas, and renewable energy power plants.

- Oil & Gas: Refinery control, exploration, and extraction automation.

- Petrochemical: Control of chemical processes and plant operations.

- Water & Wastewater: Treatment plants, sewage processing, and distribution systems.

- Manufacturing: Complex process control in industries such as food and beverage, pharmaceuticals, and automotive.

Competitive Comparison:

Compared to PLC modules from manufacturers like Siemens, Schneider Electric, or Honeywell, the Westinghouse 5X00070G04 excels in:

- Industry-Specific Applications: Strong presence in the power generation and petrochemical sectors where high performance and safety are critical.

- Safety and Compliance: SIL 2/3 compliance ensures safe operation in critical environments, making it ideal for high-risk industries.

- Redundant Systems: Provides fail-safe features and system redundancy, which are essential for mission-critical operations.

The WESTINGHOUSE 5X00070G04 DCS PLC module is designed for industries that demand precision, safety, and reliability in process control. It offers a scalable, modular design that supports high-performance automation, real-time diagnostics, and robust safety features, making it well-suited for energy, manufacturing, and other mission-critical industries.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922