الوصف

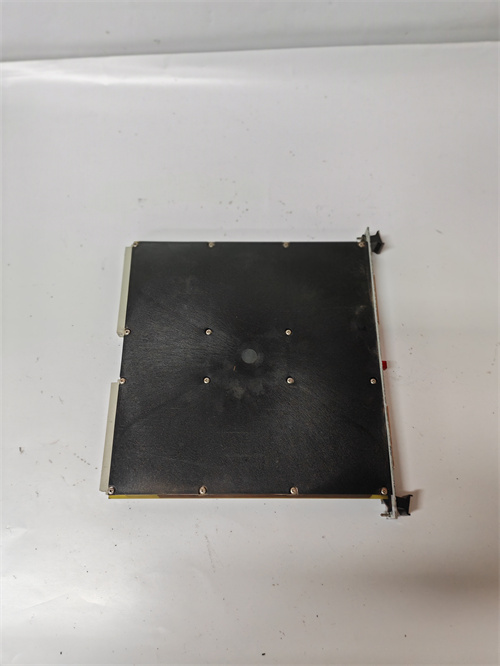

The WOODWARD 5466-5000 is a specific and essential component within Woodward’s industrial control systems. It’s identified as a 4-channel Speed Sensor Module that specifically uses MPU (Magnetic Pick-Up) inputs.

This module is a critical part of monitoring the rotational speed of machinery like turbines and compressors. It takes the raw signals from MPU speed sensors and converts them into usable data for the MicroNet control system, which then uses this information for precise control, protection, and alarming.

1. SEO-Optimized Titles:

- WOODWARD 5466-5000: MicroNet 4-Channel MPU Speed Sensor Module.

- WOODWARD 5466-5000: Magnetic Pick-Up Speed Input for Woodward Control.

- WOODWARD 5466-5000: Industrial Speed Monitoring Module for Turbines.

- WOODWARD 5466-5000: MicroNet Digital Controller Speed Input.

- WOODWARD 5466-5000: Woodward MPU Sensor Interface for RPM Measurement.

- WOODWARD 5466-5000: High-Accuracy Speed Sensing for Rotating Machinery.

- WOODWARD 5466-5000: 4-Channel Speed Input for MicroNet Plus/TMR.

- WOODWARD 5466-5000: Woodward Module for Overspeed Protection.

- WOODWARD 5466-5000: Engine/Turbine Speed Sensing via MPU.

2. Product Overview:

The WOODWARD 5466-5000 is a 4-channel Speed Sensor Module designed for use with Woodward’s MicroNet Digital Controller Series (including MicroNet Plus and often compatible with MicroNet TMR systems). Its primary function is to receive and process speed signals exclusively from Magnetic Pick-Up (MPU) transducers. This module accurately measures the rotational speed of machinery, providing critical data for control algorithms, overspeed protection, and performance monitoring.

- Product Type: Speed Sensor Module

- Manufacturer: Woodward

- Series: MicroNet Digital Controller Series (MicroNet Plus, MicroNet TMR)

- Channels: 4 channels

- Input Type: Magnetic Pick-Up (MPU)

- Function: Measures and processes rotational speed for control and protection.

3. Detailed Product Description:

Accurate and reliable speed measurement is fundamental to the control and protection of high-speed rotating machinery. The WOODWARD 5466-5000 is specifically engineered to fulfill this critical role within Woodward’s advanced control systems.

The 5466-5000 is a 4-channel Speed Sensor Module that integrates seamlessly into a MicroNet Plus or MicroNet TMR chassis. Its sole purpose is to convert raw frequency signals from Magnetic Pick-Up (MPU) sensors into precise speed readings. MPU sensors are widely used in industrial applications due to their robust nature and ability to generate a signal directly proportional to the rotational speed, typically from a gear tooth or other ferrous discontinuity.

Each of the module’s four channels independently processes the MPU input, providing real-time speed data to the main CPU. This data is then used by the control system for various functions, including:

- Speed Control: Maintaining desired operating speeds for optimal performance.

- Acceleration Limiting: Preventing excessive acceleration during starts or load changes.

- Overspeed Protection: Triggering shutdowns or alarms if the machinery exceeds safe operating speeds, a critical safety feature.

- Synchronization: Matching speeds of multiple machines (e.g., generators being paralleled to a grid).

The 5466-5000 is designed for high reliability and accuracy. It features internal processing that handles signal conditioning and filtering to ensure clean and stable speed measurements, even in noisy industrial environments. Importantly, this module requires no calibration and has no potentiometers for adjustment, simplifying installation and replacement. If you replace a faulty 5466-5000 with a new one, no adjustments are needed, provided it’s the same unit number in the chassis.

It is backward compatible, but if used as a direct replacement for very old units, it might need to be paired with a specific module like the 5464-658 for full functionality. The module can be used in both simplex (single controller) and redundant (multiple controllers) systems, offering flexibility for different application requirements.

Key Features and Benefits:

- 4 Independent Channels: Allows for monitoring of multiple speed points on a single machine or from different machines, providing redundancy or comprehensive data.

- MPU Input Specific: Optimized for reliable and accurate measurement from Magnetic Pick-Up sensors.

- High Accuracy: Delivers precise speed measurements crucial for machine control and protection.

- No Calibration Required: Simplifies installation, maintenance, and replacement, reducing downtime and human error.

- Robust Signal Processing: Includes features like speed filtering to ensure stable readings in challenging environments.

- Wide Input Frequency Range: Typically supports inputs from 50 Hz to 25 KHz, accommodating a wide range of machine speeds.

- Broad Compatibility: Compatible with both MicroNet Plus and MicroNet TMR control systems, offering versatility.

- Designed for Industrial Environments: Built to withstand typical industrial conditions with an operating temperature range.

Technical Specifications:

Typical Applications:

The WOODWARD 5466-5000 is essential in any application requiring accurate and reliable speed measurement for control and protection of rotating machinery.

- Gas and Steam Turbines: Measuring rotor speed for starting, acceleration, normal operation, and critical overspeed protection.

- Compressors: Monitoring shaft speed to prevent surge and ensure efficient operation.

- Generators: Measuring generator RPM for synchronization, load sharing, and protection.

- Diesel and Gas Engines: Providing accurate speed feedback for engine governing and safety functions.

- Pumps and Motors: Monitoring the speed of critical pumps and large electric motors in various industrial processes.

Related Products and Solutions:

The WOODWARD 5466-5000 integrates seamlessly with other components of the Woodward MicroNet system:

- Woodward MicroNet Plus/TMR CPUs: The main control processors (e.g., 5466-1035, 5466-1247, 5466-1511) that utilize the speed data provided by the 5466-5000.

- Woodward MicroNet Chassis: The physical rack that houses the 5466-5000 and other modules.

- Magnetic Pick-Up (MPU) Sensors: The field devices that generate the raw speed signals for the module.

- Field Terminal Modules (FTMs): These may be used for wiring connections from the MPU sensors to the 5466-5000 module.

- Woodward GAP™ Software: The engineering software used to configure the module’s parameters (e.g., filtering, acceleration limits) and integrate the speed data into the control logic.

- Other Speed Sensor Modules: Woodward also offers modules for proximity probes (Eddy current sensors) (e.g., 5466-5001, 5466-5002, 5466-5003 which are combinations of MPU and Prox inputs).

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922