الوصف

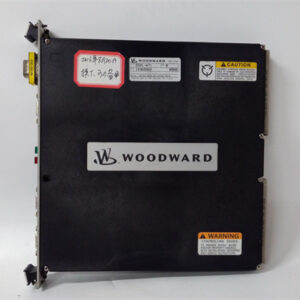

You’re asking about the WOODWARD 5466-5026. This module is a crucial component within Woodward’s MicroNet Digital Control Series, known for its high density and versatility in handling analog signals.

1. SEO-Optimized Titles:

- WOODWARD 5466-5026: High-Density Analog I/O Module (24 AI / 8 AO).

- WOODWARD 5466-5026: MicroNet Simplex Analog Input/Output Card.

- WOODWARD 5466-5026: Industrial Process Monitoring and Control Module.

- WOODWARD 5466-5026: Woodward 24-Channel Analog In, 8-Channel Analog Out.

- WOODWARD 5466-5026: Analog Signal Interface for Turbine/Engine Control.

- WOODWARD 5466-5026: High-Accuracy Analog I/O for MicroNet Plus.

2. Product Overview:

The WOODWARD 5466-5026 is a High-Density Analog Input/Output (AI/AO) Module designed for simplex operation within the Woodward MicroNet Digital Control Series (including MicroNet Plus). It offers a substantial number of analog channels on a single module, making it highly efficient for acquiring various process variables and sending analog control commands to field devices.

Specifically, it provides:

- 24 Analog Input Channels: For reading signals from sensors (e.g., temperature, pressure, flow).

- 8 Analog Output Channels: For sending precise control signals to actuators (e.g., valves, drives).

This module is a cornerstone for detailed process monitoring and fine-tuned analog control in industrial applications.

- Product Type: High-Density Analog Input/Output (AI/AO) Module

- Manufacturer: Woodward

- Series: MicroNet Digital Control (MicroNet Plus, Simplex applications)

- Channels: 24 Analog Inputs, 8 Analog Outputs

- Function: Provides extensive analog input for process monitoring and analog output for precise control.

3. Detailed Product Description:

The WOODWARD 5466-5026 is engineered to maximize I/O density and streamline the architecture of Woodward MicroNet control systems. It’s particularly valuable in applications requiring a large number of analog monitoring points and several analog control outputs within a compact footprint.

Here’s a breakdown of its capabilities:

- 24 Analog Input Channels: These channels are highly versatile, designed to monitor a wide array of process variables. They are typically software-selectable to accept standard industrial signals such as 4-20 mA current loops or 0-5 Vdc voltage signals. This flexibility allows the module to interface with a broad range of sensors for critical parameters like temperatures (bearings, exhaust), pressures (fuel, oil), flow rates, liquid levels, and more. The module performs essential signal conditioning, filtering, and high-resolution analog-to-digital conversion to deliver accurate data to the MicroNet CPU. The accuracy of the 4-20 mA input measurements is crucial for reliable data acquisition, especially in critical applications.

- 8 Analog Output Channels: These channels provide precise analog current outputs, commonly 4-20 mA. These outputs are used to drive various field control devices, such as proportional fuel valves, steam admission valves, variable speed drives, or to send analog setpoints to other local controllers. The module converts digital commands from the CPU into highly accurate analog signals, enabling dynamic and responsive control actions.

The 5466-5026 is designed for simplex operation, meaning it’s intended for control systems that do not employ triple modular redundancy (TMR). However, it offers high reliability and accuracy within this configuration. Key features typically include:

- High Accuracy: Delivers precise analog signal conversion for reliable process data acquisition and control. The accuracy of 4-20 mA input measurements is crucial for precise and reliable data acquisition.

- Electrical Isolation: Protects the control system from electrical noise and ground loops in the field wiring, ensuring signal integrity.

- No Calibration Required: Like many newer Woodward modules, it’s designed to eliminate the need for potentiometers or manual calibration. This simplifies installation, replacement, and reduces potential for human error.

- Automatic Module Detection: The MicroNet CPU can often automatically identify the presence and type of the module, streamlining system setup.

- Robust Industrial Design: Built to withstand demanding industrial environments, including high altitudes (up to 4000 meters / 13,123 feet), ensuring long-term reliability.

- Fault Indication LEDs: Front panel LEDs provide visual diagnostics for fault codes, simplifying troubleshooting.

Key Features and Benefits:

- Exceptional I/O Density: Features 24 Analog Inputs and 8 Analog Outputs on a single card, optimizing chassis space.

- Versatile Analog Inputs: Channels are software-selectable for 4-20 mA current or 0-5 Vdc voltage signals, accommodating a wide range of industrial sensors.

- Precise Analog Outputs: Drives proportional devices with standard 4-20 mA signals for accurate and dynamic control.

- High Accuracy: Ensures reliable process data acquisition and control, critical for sensitive applications.

- No Field Calibration: Simplifies installation, maintenance, and replacement by eliminating manual adjustments.

- Robust and Reliable: Designed for harsh industrial environments, ensuring long-term stable operation.

- Streamlined Configuration: Compatible with Woodward’s GAP (Graphical Application Program) and AppManager applications.

4. Technical Specifications (General, as precise details can vary slightly by manual version):

5. Typical Applications:

The WOODWARD 5466-5026 is well-suited for industrial applications requiring extensive and precise analog I/O within a single, space-efficient module, particularly in simplex control systems.

- Power Generation: Monitoring numerous temperatures, pressures, and flows (e.g., bearing temperatures, exhaust gas temperatures, fuel pressure, steam flow) on gas and steam turbines, and precisely controlling fuel valves, steam valves, or inlet guide vanes.

- Process Control: Ideal for applications in chemical plants, refineries, and other continuous process industries that require monitoring many analog variables and controlling various proportional actuators.

- Data Acquisition Systems: Where a high number of analog sensor readings need to be accurately digitized and transmitted to a control or monitoring system.

- General Industrial Automation: Any system where comprehensive analog input and output capabilities are needed for complex machinery or processes without the need for TMR redundancy.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922