الوصف

عناوين تحسين محركات البحث باللغة العربية:

- WOODWARD 8200-1401: وحدة تحكم توربينات بيلتون المائية (505HT) بجهد عالٍ

- 505HT HVAC/DC Pelton: نظام تحكم رقمي لـ WOODWARD 8200-1401

- WOODWARD 8200-1401: تحكم دقيق في سرعة وحمل توربينات بيلتون

- 505HT: حلول أتمتة متكاملة لمحطات الطاقة الكهرومائية ذات التغذية عالية الجهد

- WOODWARD 8200-1401: إدارة فوهات وقواذف توربينات بيلتون بكفاءة

- وحدة تحكم 505HT: خوارزميات متقدمة للحماية والتشغيل الآمن

- WOODWARD 8200-1401: اتصالات Ethernet و Modbus لتكامل نظام شامل

- 505HT Pelton Control: ميزات تشخيص وتسجيل أحداث متطورة

- WOODWARD 8200-1401: دعم أوضاع التحكم في السرعة، الحمل، ومشاركة الحمل (جهد عالٍ)

- لوحة تحكم التوربينات المائية 505HT: واجهة مستخدم سهلة الاستخدام وموثوقية عالية

وصف المنتج المختصر (لصفحة التفاصيل ونتائج البحث):

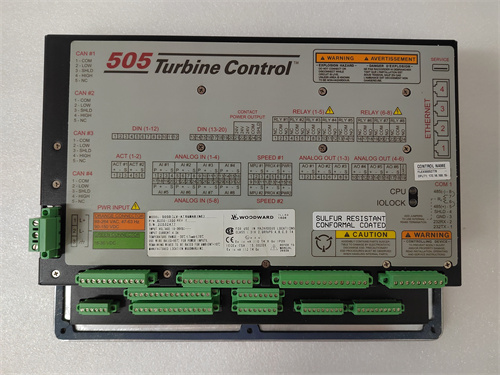

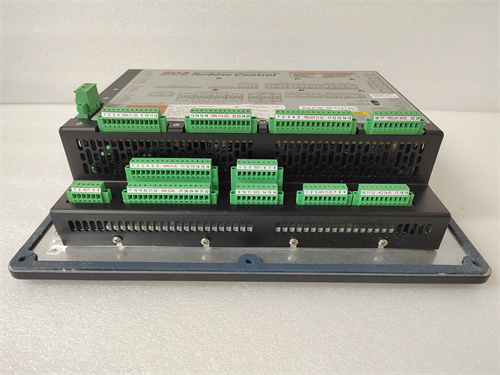

WOODWARD 8200-1401 (505HT – HVAC/DC Pelton Turbines) is a specialized, microprocessor-based digital control unit for Pelton hydro turbines, distinguished by its High Voltage AC/DC (HVAC/DC) power input. This controller offers precise speed and load regulation, along with dedicated algorithms for managing Pelton turbine nozzles and deflectors. It features advanced protection functions, extensive diagnostics, and event logging. The 8200-1401 supports multiple communication protocols (Ethernet, Modbus) for seamless integration into plant control systems and provides a user-friendly front panel for operation and configuration.

- Type: Hydro Turbine Control / Digital Governor

- Manufacturer: Woodward

- Part Number: 8200-1401

- Model: 505HT (Hydro Turbine)

- Primary Application: Control of Pelton hydro turbines.

- Key Power Feature: HVAC/DC (High Voltage Alternating Current / Direct Current) input.

- Core Functions: Speed and load control, nozzle and deflector management, advanced protection, communication capabilities.

وصف المنتج التفصيلي:

In the realm of hydropower, where high-head, low-flow conditions are best exploited by Pelton turbines, precise and robust control systems are paramount. The WOODWARD 8200-1401 (505HT) stands out as a purpose-built solution for this niche, offering not only sophisticated control capabilities but also the flexibility of High Voltage AC/DC (HVAC/DC) power input. This feature makes it highly adaptable to diverse plant electrical architectures, distinguishing it from lower voltage variants.

From an Engineer’s Perspective: Mastering Hydro Dynamics

As an engineer working with hydroelectric power, the 8200-1401 represents a refined tool for orchestrating the complex interplay of water and mechanical energy in a Pelton turbine. Here’s why it’s a critical component:

- Dedicated Pelton Control Algorithms: Unlike generic turbine controls, the 8200-1401 incorporates specialized algorithms and logic specifically for Pelton turbines. This includes:

- Nozzle Sequencing and Rotation: For turbines with multiple nozzles, the controller intelligently manages the opening and closing sequence to optimize water utilization and maintain efficiency across varying loads.

- Digital or Analog Deflector Control: This is crucial for rapid load rejection or emergency shutdowns. The deflector diverts the water jet away from the turbine runner, preventing dangerous overspeed conditions, and the 8200-1401 provides precise control over this mechanism.

- Comprehensive Control Functions: The unit offers a full suite of control capabilities to manage the turbine’s operation:

- Three Integrated PID Controllers: These enable precise offline (isolated) speed control, online (grid-connected) speed control, and baseload control, allowing the turbine to adapt to different grid demands.

- Automated Startup Routines: Ensures a safe and controlled turbine start-up sequence.

- Multiple Operating Modes: Operators can select between manual and automatic control modes, providing operational flexibility.

- HVAC/DC Power Input: This is a significant advantage. The ability to accept a wide range of high voltage AC (88–264 Vac) and DC (90–150 Vdc) power means the control can be integrated into various existing plant electrical systems without the need for additional power conversion equipment, simplifying installation and reducing costs.

- Advanced Protection Features: Safety and equipment longevity are paramount. The 8200-1401 includes robust protection functions:

- Overspeed Protection: Continuously monitors turbine speed and initiates a safe shutdown if limits are exceeded, often with redundant speed inputs for enhanced reliability.

- Small System Detection: Identifies conditions that indicate potential issues within the hydraulic or electrical system.

- Creep Detection: A vital feature for hydro turbines, it monitors for unwanted rotation of the turbine when it’s supposed to be stopped, indicating potential water leakage or mechanical issues.

- First-Out Indication: Quickly pinpoints the root cause of a shutdown, speeding up troubleshooting.

- Extensive Communication Capabilities: For seamless integration into a larger plant control system, the 8200-1401 features:

- Four Ethernet Ports: Supporting Modbus TCP and OPC protocols, enabling robust communication with plant Distributed Control Systems (DCS), SCADA systems, and other network devices.

- Serial Modbus Port: Provides an additional communication channel (RS-232 or RS-485) for Modbus ASCII or RTU protocols.

- User-Friendly Interface and Tools:

- Integrated Front Panel HMI: Allows on-site configuration and operation without needing external tools.

- Software Tools: Woodward’s RemoteView provides a graphical HMI for remote monitoring and control, while Control Assistant is used by engineers for detailed configuration, real-time data trending, and event analysis.

From a Manager’s or Purchaser’s Perspective: Maximizing ROI and Reliability

For management or procurement teams, investing in the WOODWARD 8200-1401 translates into clear benefits that impact the bottom line:

- Optimized Energy Production: Precise control over Pelton turbines leads to higher efficiency in converting water energy into electricity, directly increasing revenue.

- Enhanced System Reliability: Advanced protection features, robust diagnostics, and the ability to minimize downtime due to faults contribute to greater plant availability and reduced operational risks.

- Flexible Integration: The HVAC/DC power input allows for easier integration into existing plant infrastructure, potentially reducing installation time and costs.

- Reduced Operational Expenses: The user-friendly interface and comprehensive diagnostic tools simplify operation and maintenance, leading to lower long-term operating costs.

- Standardized Solution: As an off-the-shelf control, it reduces the need for costly custom engineering, accelerating project timelines.

From an Operator’s Perspective: Confidence and Clarity

For the operators on the ground at a hydropower plant, the WOODWARD 8200-1401 offers a smoother, safer, and more informed operating experience:

- Intuitive Control: The integrated front panel provides straightforward control over turbine operations.

- Real-time Insights: Operators have access to critical real-time data, trend screens, and event logs, enabling quick decision-making and proactive responses.

- Increased Safety: The robust protection features give operators confidence that the turbine will react safely to abnormal conditions, reducing stress and enhancing overall plant safety.

Key Technical Specifications:

Key Difference from WOODWARD 8200-1400:

The primary distinction between the WOODWARD 8200-1401 and the WOODWARD 8200-1400 lies in their power input requirements:

- 8200-1400: Designed for Pelton turbines with LVDC (Low Voltage DC) power input.

- 8200-1401: Designed for Pelton turbines with HVAC/DC (High Voltage AC/DC) power input.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922