الوصف

The search results clearly identify the WOODWARD 8200-227 as a Servo Position Controller (SPC). It’s a configurable servo/actuator driver that supports CANOpen communication, allowing for easy integration with various industrial control systems.

Key functionalities and features include:

- Purpose: Accurately positions proportional or integrating servo-valves/actuators.

- Communication: Primarily uses CANOpen for position demand signals from a system controller. Also accepts a 4-20 mA input signal as an alternative or backup.

- Feedback: Accepts feedback signals for valve position sensing from one or two (redundant) AC devices or one DC device.

- Accuracy & Redundancy: Designed with the required accuracy, responsiveness, and redundancy for critical applications like steam or gas turbine fuel valve control.

- Configuration: Configurable via a Windows-based PC interface software for tuning, calibration, and monitoring. Auto-calibration routines are available for easy setup.

- Protection & Alarms: Includes protection features and alarm indications for various faults (e.g., communication time-out, input out-of-range, feedback issues, internal faults, actuator issues, overcurrent).

- Mounting: Compact digital driver suitable for bulkhead mounting in IP20 locations.

- Power: Typically requires 18 to 32 Vdc (recommended 24 Vdc).

- Operational Modes: Supports modes like calibrate, run, configure, and manual stroke.

This device is crucial for translating digital commands from a main control system into precise physical movements of valves or other actuators in industrial processes.

WOODWARD 8200-227: Configurable Servo/Actuator Driver with CANOpen Communication (SPC)

Here’s a detailed, SEO-friendly product description for the WOODWARD 8200-227, designed for clarity, engagement, and comprehensive information.

1. SEO-Optimized Headings

- WOODWARD 8200-227: Configurable Servo Position Controller (SPC) with CANOpen

- WOODWARD 8200-227: Precision Actuator Driver for Turbine Fuel Valve Control

- Buy WOODWARD 8200-227: Robust & Redundant Servo Control for Industrial Applications

- WOODWARD 8200-227: Seamless Integration with Industrial Control Systems via CANOpen

- WOODWARD 8200-227: Advanced Valve Positioning with Dual Feedback Capability

- WOODWARD 8200-227: Simplify Setup & Tuning with PC-Based Configuration Software

- WOODWARD 8200-227 Specifications: Digital Driver for Proportional & Integrating Servo-Valves

- Installing WOODWARD 8200-227: Ensuring Accurate & Responsive Control in Critical Systems

- WOODWARD 8200-227: Enhanced Protection & Diagnostics for Industrial Actuators

- Discover WOODWARD 8200-227: Your Solution for High-Accuracy Servo Control

2. Product Overview

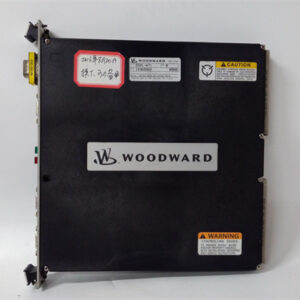

The WOODWARD 8200-227 is a highly versatile and configurable Servo Position Controller (SPC) designed for precise and reliable control of servo actuators and valves in a wide range of industrial applications. This compact digital driver excels at translating position demand signals from a main control system into accurate physical movements. Featuring robust CANOpen communication capabilities, it seamlessly integrates with various industrial networks, while also offering a 4–20 mA input for alternative or backup control. The 8200-227 is built with the accuracy, responsiveness, and redundancy vital for critical operations, such as controlling fuel valves on steam or gas turbines.

- Product Type: Servo Position Controller (SPC) / Configurable Servo/Actuator Driver

- Communication: CANOpen, 4–20 mA (input demand signal)

- Function: Accurately positions proportional or integrating servo-valves/actuators.

- Key Features: Redundant feedback capability, PC-based configuration software, built-in protection and alarms.

- Application: Steam and gas turbine fuel valve control, general industrial servo actuation.

- Power Supply: 18 to 32 Vdc (24 Vdc recommended).

3. Detailed Product Description

In complex industrial processes, precision in actuator positioning is paramount. Whether it’s a fuel valve on a turbine, a damper in a ventilation system, or a critical flow control valve, accurate and rapid response to control signals is essential for efficiency, safety, and performance. Manual adjustments are often impractical, and traditional drivers may lack the sophistication or diagnostic capabilities needed for modern, interconnected systems. This is precisely where the WOODWARD 8200-227 steps in, offering a smart and reliable solution for sophisticated servo control.

The WOODWARD 8200-227 is an integral component of Woodward’s Servo Position Controller (SPC) series. It’s not merely an amplifier; it’s an intelligent, field-programmable digital driver that bridges the gap between your main control system’s commands and the physical movement of proportional or integrating servo-valves and actuators. Its ability to communicate via CANOpen makes it an excellent choice for modern networked control architectures, ensuring efficient and reliable data exchange.

Key Features and Benefits

Precise and Responsive Actuator Positioning: The core strength of the 8200-227 lies in its ability to accurately and responsively position servo actuators. It accepts a position demand signal (primarily via CANOpen, or 4–20 mA as an alternative) from a system controller and precisely drives the connected servo-valve or actuator to the commanded position. This rapid and accurate response is crucial for maintaining tight control over critical process variables.

Robust CANOpen Communication: The integration of CANOpen communication makes the 8200-227 highly adaptable to modern industrial control environments. As a CANOpen slave device, it can be seamlessly commanded and monitored within a larger CANOpen network, simplifying wiring, enhancing data integrity, and providing flexible system architectures.

Flexible Feedback Options for Enhanced Accuracy and Redundancy: For precise valve position sensing, the SPC accepts feedback signals from various devices. It can handle feedback from one or two (for redundancy) AC LVDT/RVDT devices, or a single DC LVDT/RVDT/potentiometer. The capability to accept dual feedback signals allows the unit to switch to a healthy feedback signal if one fails, significantly enhancing the reliability and availability of the control loop.

Configurable and User-Friendly PC Interface: The 8200-227 is accompanied by a Windows-based PC interface software. This intuitive tool allows users to:

- Configure the SPC for specific actuator types and application requirements.

- Auto-calibrate the servo-valve, simplifying setup and reducing installation time.

- Dynamically adjust tuning parameters while the unit is operating.

- Monitor critical parameters in real-time.

- Manually stroke the controlled servo for testing and troubleshooting. Configurations can be uploaded and downloaded, facilitating easy deployment across multiple SPC units.

Comprehensive Protection and Diagnostics: Safety and reliability are paramount. The 8200-227 includes built-in protection features and provides clear alarm indications for various faults, such as:

- CANOpen communication time-out

- Analog input out-of-range

- Feedback open-wire or voltage out-of-range

- Position error

- Internal SPC faults

- Actuator open/short circuit

- Driver overcurrent A hard-wired shutdown contact input and relay driver output are also provided for interfacing with external protection circuits, ensuring layers of safety.

Compact and Robust Design: The SPC is designed for heavy industrial environments, suitable for bulkhead mounting in IP20 locations. Its compact footprint saves space in control cabinets, while its robust construction ensures reliable operation under demanding conditions.

Technical Specifications (Typical)

Application Areas

The WOODWARD 8200-227 is an indispensable component in critical industrial control systems where precise and reliable servo actuation is required. Key applications include:

- Steam and Gas Turbines: Primarily for highly accurate control of fuel valves, but also for steam admission valves, variable geometry components, or bleed valves.

- Compressor Control: For precise positioning of anti-surge or discharge valves.

- Industrial Engine Control: For fuel system actuation where high accuracy is needed.

- Hydro Turbines: For wicket gate or needle valve positioning.

- General Industrial Automation: Any process requiring accurate positioning of hydraulic or pneumatic servo-actuators in response to electronic commands.

Related Products

The WOODWARD 8200-227 integrates seamlessly with various other Woodward products and related industrial control components:

- Woodward Control Systems (e.g., 505, 505XT, Flex500, MicroNet Plus, NetCon): These are the primary control platforms that would issue position demand signals to the 8200-227 via CANOpen or 4-20 mA.

- Proportional and Integrating Servo-Valves/Actuators: The physical devices that the 8200-227 directly controls (e.g., Woodward TG series actuators, proportional hydraulic valves).

- LVDT/RVDT/Potentiometer Feedback Devices: Sensors providing actual position feedback to the 8200-227.

- CANOpen Network Infrastructure: Cables, terminators, and other CAN devices forming the network for communication with the main controller.

- Woodward Control System Software (e.g., GAP): Used to program the main controller that sends commands to the 8200-227.

- Woodward 8200-226: This is a related SPC model, often referred to as “Marine Certified,” indicating similar functionality but with specific marine certifications.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922