الوصف

The search results clearly identify the WOODWARD 8237-2594 as a ProTech-GII Overspeed Protection Device. It’s a highly critical safety component designed for bulkhead mounting, operates with high-voltage (HV/HV) power inputs, and features independent relays.

Here’s a detailed breakdown of its key functions and features:

- Primary Function: The ProTech-GII series, to which 8237-2594 belongs, is fundamentally an overspeed protection device. Its core purpose is to accurately determine unsafe conditions, particularly overspeed and over-acceleration, and initiate a safe and effective shutdown of turbines (gas, hydro, steam) or reciprocating engines and other plant process equipment.

- Architecture: It utilizes a Triple Modular Redundant (TMR) architecture with 2-out-of-3 voting logic. This design ensures extreme reliability and availability, as single-point failures in components (switches, transducers, modules) are detected, annunciated, and can often be repaired or replaced online without affecting the monitored system’s operation.

- Mounting: It’s designed for bulkhead mounting, providing a secure and space-efficient installation.

- Power Supply: It operates with High Voltage (HV/HV) power inputs. While specific voltage ranges aren’t in this direct search result for this part number, other ProTech-GII models often support ranges like 90-150 Vdc or 88-132 Vac.

- Relay Configuration: This specific model is characterized by independent relays. This means that each trip relay output operates independently, offering flexibility in how shutdown commands are wired and managed. (Other ProTech-GII variants might have “voted relays”.)

- Speed Monitoring: It accepts speed inputs from Magnetic Pick-Up (MPU) or PROX sensors. It can handle a wide speed range from 0.5 to 32,000 rpm, with some software enhancements allowing settings up to 80,000 rpm for turbo-expander applications (though max frequency remains 32 kHz).

- Fast Response Time: Provides a very fast response time (typically 8–26 milliseconds depending on model and configuration) to overspeed and other critical events.

- Environmental Resilience: Features a sulfur-resistant coating (for environments classified as 3C2), offering long-term resistance to SO2 and H2S gases, making it suitable for harsh industrial conditions.

- Diagnostics and Logging:

- Self-Diagnosis: Continuously monitors its own internal health.

- Online Testing: Capable of performing routine speed tests through an internal generator and logging the results, ensuring continuous functionality.

- Trip and Alarm Logging: Records all trip events, alarms, and the results of tests.

- Communication: Equipped with Modbus communication for integration with plant DCS or other control systems.

- Certifications: Certified as an IEC61508 SIL-3 (Safety Integrity Level 3) safety device, signifying its high level of safety integrity. It can be applied as a standalone IEC61508-based device or within an IEC61511-based plant safety system.

In summary, the WOODWARD 8237-2594 is a robust, highly reliable, and safety-certified overspeed protection device, crucial for safeguarding high-value rotating machinery in demanding industrial environments.

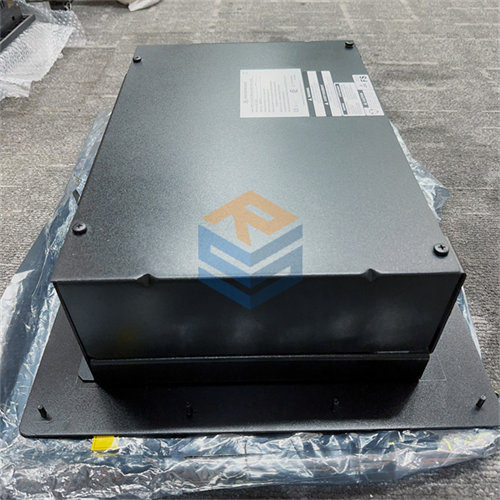

WOODWARD 8237-2594: ProTech-GII Overspeed Protection Device (HV/HV, Independent Relays, Bulkhead Mount)

The WOODWARD 8237-2594 is a vital component within Woodward’s distinguished ProTech-GII series, serving as a cutting-edge Overspeed Protection Device. This robust module is meticulously engineered to provide an unparalleled layer of safety for critical industrial assets such as steam, gas, and hydro turbines, reciprocating engines, and other plant process equipment. With its advanced design and certified safety integrity, the 8237-2594 ensures swift and precise shutdown in the event of dangerous overspeed or over-acceleration conditions.

Key Features and Benefits

- Triple Modular Redundancy (TMR) Architecture: The 8237-2594 is built upon a Triple Modular Redundant design with 2-out-of-3 voting logic. This means it utilizes three independent processing modules to continuously monitor and cross-check data. In the rare event of a single module failure, the other two “vote” to maintain correct operation, ensuring no single point of failure compromises system reliability or availability. This allows for online repair or replacement of faulty modules without interrupting the monitored system.

- Dedicated Overspeed and Over-Acceleration Protection: Its primary function is to act as a highly accurate and fast-response safety trip device. It vigilantly monitors rotor speed and acceleration, triggering a safe and controlled shutdown in milliseconds (typically 8–26 ms, model dependent) if unsafe conditions are detected.

- Independent Trip Relays: This specific model features independent relays. This configuration provides flexibility for customers to manage shutdown commands and interlocks according to their unique plant safety philosophy, allowing for distinct wiring and logic paths for critical trips.

- High Voltage (HV/HV) Power Inputs: Designed for demanding industrial environments, the 8237-2594 operates with high-voltage power inputs, providing robust electrical resilience and compatibility with standard industrial power infrastructure.

- Bulkhead Mount Design: Its bulkhead mount form factor provides a secure and space-efficient installation within control cabinets or protective enclosures, simplifying mechanical integration into existing or new control systems.

- Wide Speed Range & Sensor Compatibility: Capable of monitoring speeds from 0.5 to 32,000 rpm (with enhanced software supporting up to 80,000 rpm for specific applications like turbo-expanders). It accepts standard MPU (Magnetic Pick-Up) or PROX (proximity) sensor inputs.

- Environmental Durability: The unit boasts a special sulfur-resistant coating (meeting Class 3C2 standards for H2S and SO2 gases). This crucial feature ensures long-term reliability and operational integrity even in corrosive industrial atmospheres.

- Comprehensive Diagnostics & Online Testing:

- Self-Diagnosis: Continuously performs internal health checks.

- Online Speed Tests: An internal generator allows for routine speed tests to be performed while the system is online, ensuring the overspeed function remains fully operational without interrupting production.

- Event and Alarm Logging: Logs all trip events, alarms, and test results, providing invaluable data for incident analysis, troubleshooting, and compliance reporting.

- Modbus Communication: Supports Modbus communication for seamless integration with plant Distributed Control Systems (DCS) or other supervisory control systems, allowing remote monitoring of status, alarms, and data.

- IEC61508 SIL-3 Certified: The ProTech-GII is certified to IEC61508 Safety Integrity Level 3 (SIL-3), which represents a high level of safety integrity, making it suitable for the most critical safety instrumented functions in industrial processes.

Technical Specifications (Typical)

Application Areas

The WOODWARD 8237-2594 is an indispensable safety solution for any industrial application where the reliable protection of high-speed rotating machinery is critical:

- Power Generation Plants: Essential for safeguarding steam, gas, and hydro turbines driving generators, preventing catastrophic overspeed events that could lead to widespread power outages and significant equipment damage.

- Oil & Gas Industry: Used to protect large gas turbines and reciprocating engines driving compressors and pumps in critical upstream, midstream, and downstream operations, where safety and uninterrupted production are paramount.

- Petrochemical and Chemical Plants: Provides vital overspeed protection for turbines and other high-speed rotating equipment in continuous and potentially hazardous processes.

- Industrial Process Equipment: Applicable to any plant machinery requiring a high-integrity safety shutdown system based on speed or acceleration monitoring.

- Marine Applications: For robust engine and turbine overspeed protection on various types of marine vessels.

Related Products

The WOODWARD 8237-2594 functions as a crucial independent safety layer, often complementing or integrating within broader control architectures alongside:

- Woodward Control Systems (e.g., 505XT, MicroNet Plus, Flex500, NetCon): These systems handle the primary operational control of the turbine or engine, while the ProTech-GII provides the independent, redundant safety trip functionality.

- Emergency Shutoff Valves (ESVs) / Trip Valves: These are the physical actuators that the ProTech-GII commands to initiate a safe shutdown when an overspeed event is detected.

- Speed Pickups / Probes (MPU or Proximity): Sensors that provide the essential speed input signals to the 8237-2594 for continuous monitoring.

- Distributed Control Systems (DCS) / SCADA Systems: For overall plant monitoring and supervisory control, communicating with the ProTech-GII via its Modbus interface to receive status and alarm data.

- Woodward Service Tool Software (for ProTech-GII): Used for configuring, monitoring, and troubleshooting the ProTech-GII unit, allowing users to customize its safety logic and access diagnostic data.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922