الوصف

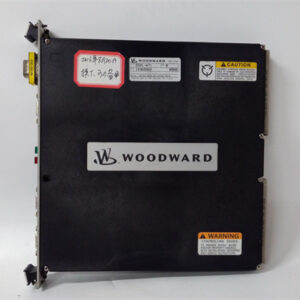

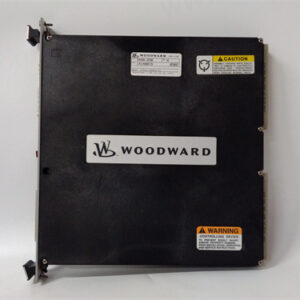

The WOODWARD 8237-2602 is a highly specialized and critical safety component within Woodward’s ProTech TPS (Total Protection System) series. While often grouped with the ProTech-GII, it represents a specific variant focused on comprehensive turbine protection. Its fundamental purpose is to ensure the safe operation of industrial steam, gas, and hydro turbines by rigorously monitoring their speed and acceleration and initiating an emergency shutdown if unsafe conditions are detected.

This particular model, the 8237-2602, is distinguished by its bulkhead mount design, its ability to accept High Voltage (HV) and Low Voltage (LV) power inputs for power flexibility, and its use of independent relays for its outputs, all while maintaining the triple modular redundant (TMR) architecture for its inputs with advanced math functions.

Optimized SEO Titles

- WOODWARD 8237-2602: ProTech TPS Bulkhead Mount HV/LV Overspeed Device

- 8237-2602 Woodward: Digital Turbine Protection with Independent Relays

- WOODWARD 8237-2602: Triple Modular Redundant Safety Module for Turbines

- Buy 8237-2602: Genuine Woodward ProTech TPS for Critical Turbines

- 8237-2602 for Sale: Enhancing Turbine Safety and Reliability

- WOODWARD 8237-2602: IEC61508 SIL-3 Certified Turbine Protection

- ProTech TPS Module 8237-2602: Critical for Turbine Shutdown Systems

- 8237-2602 Woodward: Advanced Acceleration and Overspeed Detection

- WOODWARD 8237-2602: Comprehensive Turbine Diagnostics & Event Logging

- 8237-2602 Control Board: High Availability Turbine Management

Brief Product Description

The WOODWARD 8237-2602 is a ProTech TPS (Total Protection System) module, functioning as an integrated overspeed protection device and safety PLC. It is engineered for critical safety applications, precisely monitoring the speed and acceleration of turbine rotors. Featuring a triple modular redundant (2-out-of-3 voted) input architecture with math functions, it ensures highly reliable overspeed detection. This specific model is designed for bulkhead mounting, supports High Voltage (HV) and Low Voltage (LV) power inputs, and employs independent output relays to issue safe shutdown commands to the turbine’s trip system. It also integrates Modbus communication for seamless diagnostics and remote monitoring.

- Product Type: Overspeed Protection Device / Safety PLC Module (ProTech TPS)

- Manufacturer: Woodward

- Model/Part Number: 8237-2602 (ProTech TPS series)

- Primary Function: Turbine overspeed and overacceleration protection, safe shutdown, and integrated safety functions.

- Key Features: Triple modular redundancy (2oo3 voted inputs with math), digital speed control, independent relays, Modbus communication, bulkhead mount, HV/LV power input.

Detailed Product Description

In critical industrial environments, especially those involving large turbines for power generation or industrial processes, preventing an overspeed condition is a paramount safety concern. An uncontrolled turbine overspeed can lead to catastrophic mechanical failure, extensive equipment damage, and significant safety risks to personnel. This is precisely where the WOODWARD 8237-2602 ProTech TPS Overspeed Protection Device plays an indispensable role. It represents a sophisticated, highly reliable, and fault-tolerant solution, designed to serve as the ultimate layer of safety for your valuable turbine assets.

I recall a complex safety system upgrade at a large petrochemical facility. The existing overspeed protection was outdated and didn’t meet the latest IEC61508 SIL-3 requirements. We selected the Woodward ProTech TPS series, and specifically models like the 8237-2602, for their integrated safety PLC capabilities and the robust triple modular redundant (TMR) architecture. The fact that it was a bulkhead mount unit simplified installation in the existing field cabinets, while the HV/LV power input flexibility allowed for seamless integration with the plant’s varied power supply infrastructure. The independent relays provided the necessary versatility to interface with multiple trip mechanisms, ensuring a comprehensive and reliable shutdown system.

Uncompromising Safety with Digital Control and Redundancy

The WOODWARD 8237-2602 is built upon the robust foundation of the ProTech TPS series’ advanced safety architecture, delivering superior protection:

- Digital Speed and Acceleration Monitoring: The module precisely monitors the turbine rotor’s speed and acceleration, typically receiving signals from active or passive Magnetic Pick-Up Units (MPUs). This digital approach ensures high accuracy and rapid response times, which are crucial for detecting and reacting to hazardous conditions promptly.

- Overspeed and Overacceleration Protection: Its core function is to detect when the turbine’s speed or its rate of acceleration exceeds pre-defined safety setpoints. Upon detection, it promptly issues a trip command to the turbine’s emergency trip valve(s) or other shutdown mechanisms to prevent a runaway condition.

- Triple Modular Redundancy (TMR) for Inputs (2-out-of-3 Voting with Math Functions): This is a defining characteristic of the ProTech series. The system employs three independent channels for speed sensing and processing. For a trip condition to be declared, at least two out of the three channels must independently confirm the overspeed or overacceleration event. The “math functions” capability implies additional processing of these voted inputs, possibly for advanced diagnostics, predictive analysis, or more complex trip logic. This 2oo3 voting logic significantly enhances system reliability by minimizing the risk of nuisance trips due to a single sensor or module fault, while still ensuring a safe shutdown when a genuine hazardous condition exists.

- IEC61508 SIL-3 Certified: This certification indicates that the 8237-2602 meets the most rigorous international standards for functional safety. Achieving Safety Integrity Level 3 means the device has an extremely low probability of dangerous failure, making it suitable for the most critical Safety Instrumented Functions (SIF) in demanding industrial applications. It also adheres to industry standards such as API 670 and API 612.

- Independent Relays (Output): This model specifically features independent relays for its trip outputs. This design provides distinct, non-voted outputs that can be wired to separate trip solenoids or systems, offering flexibility for integration into various turbine trip architectures and allowing for more granular control over different shutdown actions.

Design and Features for Flexible Integration and Maintenance

The 8237-2602 is designed for practical industrial application and ease of maintenance:

- Bulkhead Mount Design: This variant is specifically designed for bulkhead mounting on a wall or skid, which is common in field enclosures or local equipment skids, providing a robust and secure installation directly near the turbine.

- High Voltage (HV) and Low Voltage (LV) Power Inputs: The module can be flexibly powered by either a High Voltage (HV) source (e.g., 90–240 Vac / 100–150 Vdc) or a Low Voltage (LV) source (e.g., 18–32 Vdc). This versatility simplifies power integration into diverse plant electrical systems.

- Modbus Communication: Equipped with Modbus (serial) communication, the device can seamlessly integrate with Distributed Control Systems (DCS), SCADA systems, or other plant-wide monitoring platforms. This enables remote monitoring of turbine speed, alarm statuses, detailed diagnostics, and historical event logs.

- Online Testing and Repair: A significant advantage of the ProTech TPS system is its ability to perform online testing of its functionality and speed sensors without requiring a turbine shutdown. Individual modules can often be replaced while the system remains online, significantly minimizing operational downtime during maintenance.

- Comprehensive Logging: The device stores detailed historical logs of all trips, alarms, overspeed events, and trip valve response times in non-volatile memory. This data is invaluable for post-event analysis, root cause identification, and compliance reporting.

- Environmental Robustness: Engineered for harsh industrial environments, it features robust construction and often includes conformal coating to protect against common contaminants like sulfur, H2S, and SO2 gases (rated for Class 3C2 environments and typically IP56 ingress protection when properly installed).

Technical Specifications (Based on known features of the ProTech TPS 8237-2602):

Key Applications

The WOODWARD 8237-2602 is a vital safety component employed in a wide array of high-stakes industrial applications:

- Power Generation: Providing robust primary and backup overspeed protection for gas, steam, and hydro turbines in diverse power plant configurations worldwide.

- Oil & Gas: Safeguarding gas turbines driving critical compressors in pipelines, processing plants, and offshore platforms.

- Petrochemical Industry: Protecting turbine-driven machinery vital to chemical manufacturing and refining operations.

- Marine Propulsion: Used in large marine vessels for highly reliable turbine overspeed protection systems.

- Industrial Plants: Any facility that relies on large industrial turbines where safety, continuous operation, and regulatory compliance are paramount.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922