الوصف

The Woodward 8256-260 is a specific part number for a ProAct™ Actuator, which is a crucial component in Woodward’s Electrically Powered Governor (EPG) and ProAct Digital Control systems. It is not a complete governor or speed controller on its own, but rather the electromechanical device that translates electrical commands into precise mechanical movement.

WOODWARD 8256-260: ProAct™ Actuator (Often Paired with a Driver)

The Woodward 8256-260 is a ProAct™ actuator that converts electrical signals from a Woodward electronic control unit (like a ProAct Speed Control or Fuel Limiter) into precise mechanical action. This mechanical output then adjusts the fuel rack, throttle body, or other control linkage on a prime mover (engine or turbine).

Product Overview

- Product Type: Electro-mechanical Actuator

- Manufacturer: Woodward

- Series: ProAct™ Actuator (often specifically referenced as part of the “ProAct 75” family, implying a certain work output capability)

- Function: Receives an electrical command signal (typically from a ProAct electronic controller or a dedicated driver module) and translates it into a proportional rotary or linear mechanical output to control fuel or air to an engine.

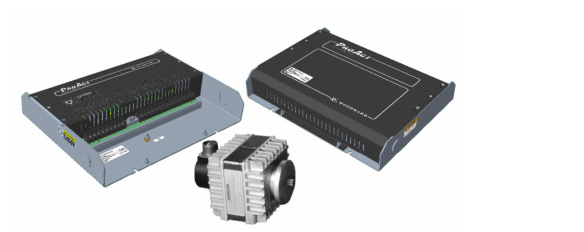

- Key Feature: This actuator typically functions as part of a system and often requires a separate ProAct Driver module (e.g., 8400-011, 8400-706, 8400-020, 8400-704) to provide the necessary power and signal conditioning to operate correctly.

- Operation: It’s an electrically powered device that provides precise positioning, often incorporating internal return springs for fail-safe operation (returning to a predefined position, usually a “decrease-fuel” or “shutdown” position, upon loss of signal or power).

Detailed Description

Woodward ProAct actuators are known for their robust construction, high precision, and fast response, making them essential components in demanding industrial applications where accurate prime mover control is critical. The 8256-260 plays a vital role in these systems by providing the physical force and precise movement required.

Key characteristics of the 8256-260 include:

- Electromechanical Operation: The actuator uses an internal electric motor (often a high-efficiency torque motor) to drive its output shaft. The exact position of this output shaft is directly proportional to the electrical command signal it receives from the associated controller/driver.

- Precise Positioning: Designed to deliver accurate and repeatable positioning, which is paramount for maintaining stable engine speed, precise load control, or accurate air/fuel ratio management.

- Fail-Safe Mechanism: Incorporated return springs ensure that the actuator moves to a safe, pre-defined position (e.g., fuel cut-off or minimum fuel) if the electrical control signal is lost or if power to the actuator is removed. This is a critical safety feature.

- Driver Dependent: For the 8256-260, its operation is intrinsically linked to a compatible ProAct Driver module. The driver serves as an interface, supplying the necessary power (e.g., 12 Vdc or 24 Vdc, depending on the system) and often performing some signal amplification or conditioning for the actuator.

- Robust Construction: Housed in a durable casing (typically cast aluminum), it’s engineered to withstand the harsh conditions commonly found in engine environments, including significant vibrations, wide operating temperature ranges, and electromagnetic interference.

- Wide Rotational Angle: ProAct actuators are generally capable of a wide rotational angle (e.g., up to 60 degrees of travel) which allows them to operate various fuel control linkages effectively, even those with significant travel requirements.

Applications

The Woodward 8256-260 (as an integral part of a ProAct system) is commonly used in critical control loops for:

- Diesel Engines: Controlling fuel racks on diesel engines for precise speed control, load management, and startup fuel limiting.

- Gaseous Engines: Adjusting gas valves, mixer linkages, or throttle bodies for accurate speed, load, and air/fuel ratio control in natural gas, propane, or other gaseous-fueled engines.

- Gas Turbines: Manipulating fuel valves or inlet guide vanes for power and speed control.

- Power Generation: Essential for the precise speed and load control of engine-driven generator sets to ensure stable electrical frequency and efficient power production.

- Industrial Pumps & Compressors: Where engines drive these machines, the actuator ensures accurate speed or flow regulation.

Related Products/Series

The 8256-series generally refers to ProAct actuators, while the 8400-series covers ProAct controllers and drivers. Other related part numbers in the ProAct ecosystem include:

- 8256-259: A very similar ProAct Actuator. Differences between the -259 and -260 might be minor revisions, specific output shaft configurations, or slight performance variations. They are often listed together as part of the ProAct 75 Driver + Actuator family.

- 8256-022: A commonly referenced EPG (Electrically Powered Governor) Actuator, often referred to as a “Model 512” actuator.

- 8400-704 / 8400-020: Common ProAct Driver modules designed to pair with actuators like the 8256-260.

- 9907-1290: A ProAct Model II Digital Speed Control, which would typically send its command signals to a ProAct actuator.

- 9907-1291: A ProAct Plus Digital Fuel Limiter, which also sends control signals to the actuator to provide an overriding fuel limit.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922