الوصف

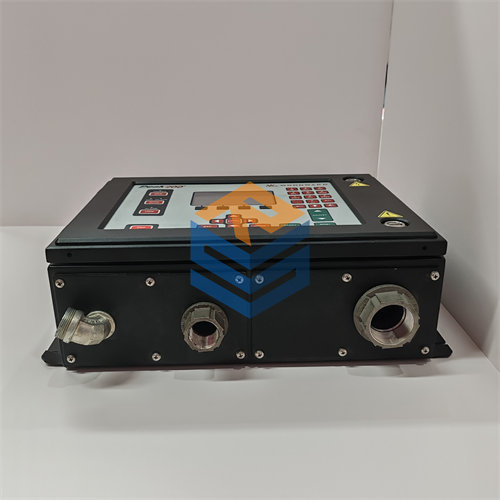

The WOODWARD 8262-3182 is a specific configuration of a Standard MicroNet+ Kit from Woodward. This isn’t a single, standalone I/O module, but rather a pre-assembled package of core hardware components designed to form a complete control system.

WOODWARD 8262-3182: MicroNet+ Standard Kit with Specific I/O and Redundant Power

The WOODWARD 8262-3182 designates a particular configuration within the Standard MicroNet+ Kit series. These kits are comprehensive solutions providing the foundational hardware for controlling prime movers (like gas turbines, steam turbines, or engines) and associated industrial processes.

Product Overview

This specific kit configuration is characterized by:

- 8-Slot Chassis: This is the physical enclosure that houses the various MicroNet+ control modules, providing the backplane and structural support.

- 2 x 120 V AC/DC Power Supplies (PS): This indicates the inclusion of redundant power supplies, capable of accepting either 120 V AC or 120 V DC input. This redundancy is crucial for enhanced system reliability, ensuring continuous operation even if one power source fails. The AC/DC compatibility offers flexibility in power infrastructure.

- Speed Input Module: This kit includes or is configured for a module designed to accurately measure speed signals, which are critical for prime mover control.

- Analog Combo Module: This signifies the presence of a module that combines both analog input and analog output capabilities.

- Relay Drivers: This suggests the kit includes or is configured for discrete output modules capable of directly driving external relays for on/off control.

This comprehensive combination makes the 8262-3182 a versatile and robust kit, suitable for applications that require precise speed measurement, a mix of analog and discrete control, all backed by a flexible and redundant power system.

- Product Type: Standard MicroNet+ Hardware Kit Configuration

- Manufacturer: Woodward

- Series: MicroNet+ Digital Control Systems

- Key Components: 8-slot chassis, redundant 120 V AC/DC power supplies, speed input module, analog combination module, and relay drivers (discrete outputs).

- Function: Provides the foundational hardware for a robust industrial control system, capable of managing complex turbine, engine, or process control applications requiring speed sensing and mixed I/O.

Detailed Product Description

Woodward’s MicroNet+ is a powerful and adaptable digital control platform widely employed across various industries for prime mover and process control. The 8262-3182 is one of several pre-configured “Standard MicroNet+ Kits” that Woodward offers to streamline the deployment and integration of these sophisticated control systems.

This specific kit, the 8262-3182, is designed to deliver a comprehensive set of capabilities:

- Chassis and Redundant Power: It features an 8-slot chassis, serving as the backplane and enclosure for the MicroNet+ processor and I/O modules. A critical aspect is the inclusion of two 120 V AC/DC power supplies. This dual-supply configuration provides power redundancy, meaning if one power supply fails, the other can seamlessly take over, significantly boosting the system’s reliability and ensuring continuous operation in critical applications. The ability to accept either AC or DC power offers flexibility in different plant electrical infrastructures.

- Comprehensive I/O Capabilities:

- Speed Input Module: This is crucial for prime mover control, accurately measuring rotational speed via various speed sensor types. This data is essential for governing speed, overspeed protection, and synchronization.

- Analog Combo Module: This module enables the system to read continuous input signals (e.g., 4-20 mA from pressure, flow, or temperature transmitters) and generate continuous output signals (e.g., 4-20 mA to proportional control valves or variable speed drives). This combination provides versatile analog monitoring and control capabilities.

- Relay Drivers: The kit is configured with (or designed to accommodate) discrete output modules that can directly switch external relays. These are used for on/off control of various plant equipment, such as starting/stopping pumps, activating solenoid valves, or controlling alarms and indicators.

- System Integration: As a MicroNet+ kit, it’s engineered for seamless integration with other Woodward modules, including various processors (CPUs) and any additional specialized I/O cards (e.g., RTD/thermocouple inputs) to form a complete, tailored control solution.

- Programming: The entire MicroNet+ system, including the functionality enabled by this kit, is custom-programmable using Woodward’s Graphical Application Program (GAP™) software. This powerful software allows engineers to develop complex control logic, sequencing routines, protection schemes, and performance optimization algorithms specifically adapted to the machinery or process being controlled.

- Robustness and Reliability: MicroNet+ systems are built to withstand the rigors of industrial environments, including wide temperature ranges, vibration, and electrical noise. While this kit is classified as “Standard,” it still offers high reliability and can be a foundational component for redundant or even Triple Modular Redundant (TMR) architectures, depending on the overall system design.

In summary, the 8262-3182 kit provides a foundational, versatile, and highly reliable hardware base for implementing advanced control strategies in industrial prime mover and process control applications, particularly where precise speed sensing, mixed analog and discrete I/O, and flexible/redundant 120 V AC/DC power are key requirements.

Technical Specifications (General)

As a kit, detailed specifications apply to the included components. However, based on the description:

Typical Applications

The WOODWARD 8262-3182 kit is ideally suited for a wide range of critical industrial applications where reliable and flexible control of prime movers and associated processes is required:

- Gas Turbine Control: Comprehensive control from start-up through various operating states (acceleration, loading/unloading, steady-state) to safe shutdown. This includes precise speed control, fuel metering, temperature management (EGT), vibration monitoring, and safety interlocks.

- Steam Turbine Control: Governing speed, load, extraction/admission pressures, and other process parameters.

- Industrial Engine Control: Managing speed, fuel delivery, and protection for various industrial engine applications.

- Compressor Control: Implementing anti-surge control, load sharing, and station control for large industrial compressors.

- Power Generation: Providing the core control for generators (including synchronization and load sharing) and their auxiliary systems.

- Mechanical Drive Systems: For precise control in applications where a prime mover drives mechanical equipment like pumps or fans.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922