الوصف

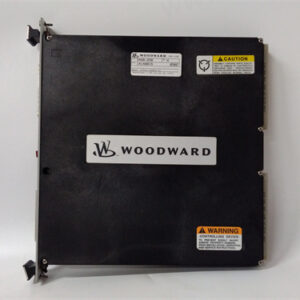

The WOODWARD 8269-1073 is a specialized 17-inch TouchPanel Operator Control Panel (OCP). It’s not a turbine controller itself, but rather a dedicated Human-Machine Interface (HMI) and engineering workstation designed for seamless integration with Woodward’s 5009XT Industrial Steam Turbine Control systems.

This unit comes pre-loaded with Woodward’s RemoteView software, which acts as the crucial link between the operator/engineer and the powerful 5009XT controller. Its purpose is to provide a comprehensive and intuitive visual interface for monitoring, controlling, configuring, and diagnosing the complex operations of industrial steam turbines.

Key Features and Benefits:

Operator and Engineering Interface

The 8269-1073 serves as the primary Human-Machine Interface (HMI) for the 5009XT system. Its large 17-inch touchscreen allows operators to easily:

- Monitor real-time turbine parameters: This includes critical data like speed, load, various steam pressures (inlet, extraction, exhaust), and plant import/export power.

- Control turbine operations: Operators can initiate turbine starts and stops, enable or disable different control modes, and adjust setpoints directly from the panel.

- View alarms and events: The panel displays time-stamped alarms and faults (down to one-millisecond resolution), aiding in rapid troubleshooting and pinpointing the root cause of issues. It also supports “first-out” indication for critical shutdowns.

- Access historical data and trends: Providing insights into past performance and system behavior.

RemoteView Software Integration

The pre-installed RemoteView software is central to the 8269-1073’s functionality. RemoteView is a flexible program that allows the OCP to act as a remote operator station or an engineering workstation. It uploads the specific Graphical User Interface (GUI) application program from the connected 5009XT controller, essentially mirroring the controller’s front panel display. This allows for:

- Comprehensive Monitoring: Displaying all governor and turbine parameters.

- Configuration and Tuning: Engineers can use it to make system configuration changes, calibrate sensors, and tune control loops without needing to be physically at the controller.

- Multi-level Security: Password-based security levels ensure that only authorized personnel can access critical functions and make changes to the system.

- Redundant Connection: The RemoteView display can be networked to all three CPUs of the 5009XT system for maximum redundancy, ensuring continuous monitoring even if one CPU fails.

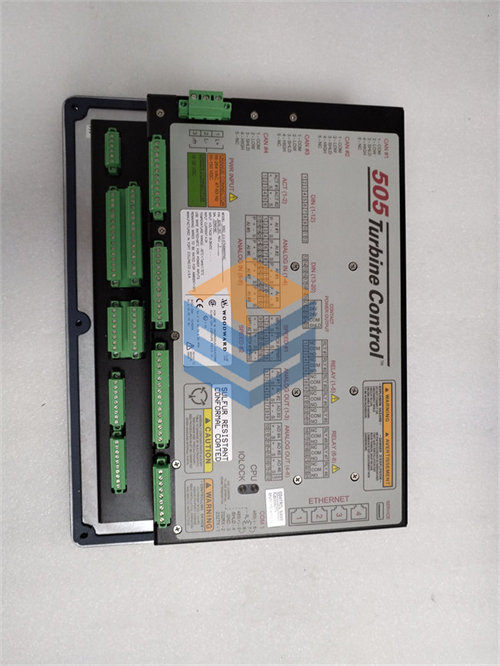

Designed for 5009XT Steam Turbine Control Systems

The 8269-1073 is purpose-built to complement the 5009XT Industrial Steam Turbine Control system. The 5009XT is known for its Triple Modular Redundant (TMR) hardware platform, providing exceptional fault tolerance and reliability for critical turbine applications. The 8269-1073 enhances this reliability by offering a robust and intuitive interface for managing such a sophisticated control system.

Benefits for Different Roles:

- For Operators: Provides an intuitive and clear interface for daily operations, enabling quick responses to changing conditions and immediate access to critical system information.

- For Engineers: Serves as a powerful workstation for detailed system configuration, diagnostics, and troubleshooting, helping to reduce downtime and optimize turbine performance.

- For Management/Owners: Contributes to increased plant reliability, reduced operational costs through efficient troubleshooting, and optimized energy production from steam turbines.

Technical Specifications (Summary):

- Manufacturer: Woodward

- Part Number: 8269-1073

- Type: 17-inch TouchPanel Operator Control Panel (OCP)

- Primary Software: RemoteView (pre-loaded and licensed)

- Application: Human-Machine Interface (HMI) and Engineering Workstation for Woodward 5009XT Industrial Steam Turbine Control Systems

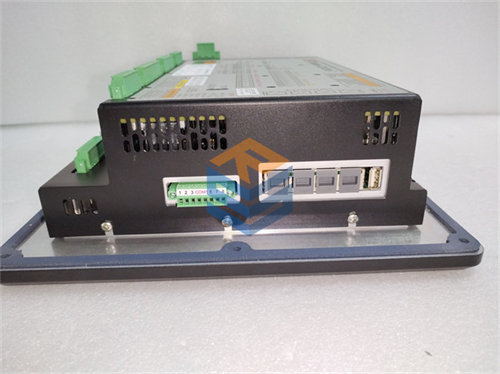

- Interface: Touchscreen, graphical user interface (GUI)

- Connectivity: Typically via Ethernet to 5009XT CPUs

- Functionality: Real-time monitoring, control command issuance, alarm/event display, data trending, configuration, and diagnostics.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922