الوصف

The Woodward 8335-005 is a specific part number that identifies another model within the ProAct™ Integrated Speed Control (ISC) family. Similar to the 8335-004, it’s a highly advanced and integrated electronic actuator with an onboard digital driver, designed for precise control of diesel or gaseous engines. The difference between the -004 and -005 would typically be a specific variant in torque output, input/output configuration, or a slight mechanical variation.

WOODWARD 8335-005: ProAct™ Integrated Speed Control (ISC)

The Woodward 8335-005 is an electric actuator with an integrated electronic driver and control capabilities. It’s part of the ProAct™ ISC (Integrated Speed Control) series, offering a compact and powerful solution for engine speed control or positioning tasks.

Product Overview

- Product Type: Integrated Speed Control (ISC) / Electric Actuator with Integral Driver

- Manufacturer: Woodward

- Series: ProAct™ ISC

- Function: Can be configured for either speed control (maintaining a target engine RPM) or positioning tasks (driving to a specific output shaft angle).

- Key Feature: Its “integrated” nature means the actuator and its electronic driver are housed in a single unit, simplifying installation and reducing wiring complexity compared to separate components. It also contains onboard software for control, monitoring, and customization.

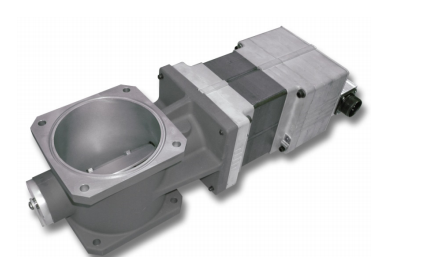

- Engine Types: Capable of controlling both diesel fuel racks and gaseous throttle valves via direct linkage or by mounting directly to Woodward integrated throttle bodies.

- Input: Accepts a speed input from a Magnetic Pickup Unit (MPU) for speed control, and/or a position command signal from another device (like an engine control module – ECM) for positioning tasks. It can accept various command inputs including PWM, 0–5 V, or CAN.

- Output: Features a 0.625-inch (0.625-36) serrated tooth shaft for robust mechanical connection. It offers a 75° (±2°) rotary output.

- Power Input: Typically requires 18–32 Vdc power supply (compatible with 12V or 24V nominal systems) with reverse polarity protection and out-of-range diagnostics. Maximum power consumption is usually around 32 W.

- Work Output: Capable of providing up to 2.3 J (1.7 ft-lb) of available work.

Detailed Description

The Woodward ProAct ISC (including the 8335-005) provides a highly capable and self-contained solution for engine control.

Key characteristics of the 8335-005:

- All-Electric Actuator: Requires no external drive or hydraulic supply, simplifying system design, reducing maintenance, and offering a clean solution.

- Integrated Digital Driver: The onboard digital driver is intelligent, capable of precisely controlling the actuator, communicating with external control systems (e.g., via CAN 2.0B serial communications for functions like boost fuel limit), and performing monitoring/customizing functions via its software.

- Dual Functionality:

- Speed Control: Offers features like software-selectable speed setpoints (e.g., idle/rated), adjustable dynamics, fuel limiting (including start-fuel limit for smoke control), droop control (0 to 10% of set speed with 1/10% resolution), and various analog/discrete inputs/outputs for modifiers. It supports isochronous speed control and load sharing accessories.

- Position Control: Provides precise position control with software-selectable CW/CCW operation and field calibration.

- Robust Mounting: Can be base- or flange-mounted directly on the engine and is designed to withstand high levels of vibration (e.g., US MIL-STD-202F, procedure 214A) and wide temperature extremes (operating range typically -40 °C to +105 °C, storage -40 °C to +125 °C).

- Fast and Precise: Extremely fast, bi-directional electric actuator, electronically positioned in both directions with high accuracy (typically ±2% at 25°C, ±4% over full temperature range for analog input) and repeatability. Max slew rate can exceed 1000 degrees/second.

- Configurable Parameters: Its internal software, accessible via a PC-based Service Tool, allows for extensive parameter customization, diagnostics, and troubleshooting.

- Safety Features: Includes a return spring to ensure it moves to a minimum fuel/air position upon loss of power, complying with safety specifications like US DOT 571.124.

Applications

The Woodward 8335-005 is widely used in various applications where precise and reliable engine control is essential:

- Power Generation: For controlling speed and load of engine-driven generator sets to ensure stable electrical frequency and efficient power production.

- Gaseous Engines: Precisely controlling throttle valves or fuel metering for applications requiring tight air/fuel ratio control and emissions compliance.

- Diesel Engines: Controlling fuel racks for speed governing, load sharing, and limiting. It can also integrate with fuel injection pumps (e.g., Stanadyne DB-series or Delphi DP200 & DP210) using optional mounting kits.

- Industrial Applications: Anywhere prime movers are used, such as in pumps, compressors, and marine propulsion systems, where electronic speed or position control is required.

- Integrated Throttle Bodies (ITBs): Can be mounted directly to Woodward’s Flo-Tech Integrated Throttle Bodies (like those in the 8235-series) to create a complete airflow control solution without external linkages.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922