الوصف

The Woodward 8400-061 is a specific part number for a ProAct™ Digital Speed Control System. It is a crucial electronic control module used for precise speed regulation of various prime movers, such as diesel or gaseous engines.

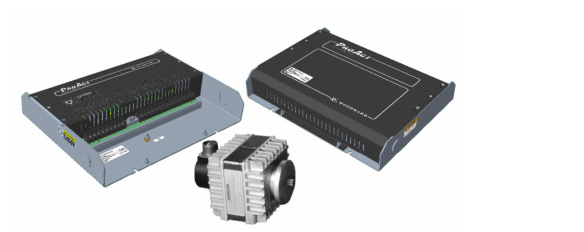

WOODWARD 8400-061: ProAct™ Digital Speed Control System

The Woodward 8400-061 is a component within the ProAct™ Digital Speed Control System, specifically functioning as a speed controller. It plays the central role in monitoring engine speed and sending commands to an actuator to maintain a desired speed.

Product Overview

- Product Type: Digital Speed Control System / Speed Controller

- Manufacturer: Woodward

- Series: ProAct™ Digital Speed Control (associated with ProAct Models I and II)

- Function: Electronically regulates the speed of an engine or turbine by processing speed sensor signals and generating a command for an actuator (which in turn controls fuel or air).

- Key Feature: This part number is often listed in documentation regarding updates or changes to the ProAct series, sometimes alongside the 8400-055, indicating it’s a specific variant or revision within that family.

- Integration: It typically works as part of a larger control loop, receiving feedback from a speed sensor (like a magnetic pickup) and sending a command signal to a compatible Woodward ProAct actuator. In some configurations, an intermediate ProAct driver module might be used between the controller and the actuator.

Detailed Description

The ProAct™ Digital Speed Control Systems are renowned for their advanced microprocessor-based control, offering high precision, fast response, and robust performance in demanding industrial applications. The 8400-061 serves as the intelligent core of this system, ensuring stable and accurate prime mover operation.

Key characteristics of the 8400-061 include:

- Digital Control: It utilizes sophisticated digital algorithms to continuously monitor engine speed (typically via an AC signal from a magnetic pickup unit, or MPU). It then compares this actual speed to a user-defined speed reference and calculates the necessary output signal to drive the actuator.

- Precise Speed Regulation: This controller is essential for applications demanding very stable speed, such as generator sets that need to maintain a constant electrical frequency, or industrial equipment that requires consistent operational speed for optimal process control.

- Control Algorithms: The embedded software incorporates advanced PID (Proportional-Integral-Derivative) control algorithms, allowing for fine-tuning of the system’s dynamic response to load changes and disturbances.

- Programmability: ProAct controllers are highly configurable. Using Woodward’s PC-based service tools (e.g., ProAct ISC & P-Series Service Tool), users can adjust various parameters, including speed setpoints (idle, rated), acceleration/deceleration ramps, fuel limiting curves (start fuel, max fuel, torque limit), and diagnostic settings.

- Comprehensive Diagnostics: The unit often includes built-in diagnostic capabilities that can detect and signal fault or error conditions, aiding in troubleshooting and minimizing downtime.

- Robust Design: Built to withstand the harsh environmental conditions typically found around engines, including vibrations, temperature extremes, and electromagnetic interference.

Applications

The Woodward 8400-061 (and the ProAct Digital Speed Control system it’s a part of) is widely applied in critical control loops for:

- Power Generation: For precise speed and load control of diesel or gaseous engine-driven generator sets, ensuring stable electrical frequency and efficient power production.

- Industrial Engine Control: For a wide array of industrial engines driving pumps, compressors, fans, or other machinery where accurate and responsive speed regulation is paramount.

- Marine Propulsion: In certain marine applications, for main engine speed control to maintain vessel speed or propeller pitch.

- Cogeneration Systems: Where efficient and reliable engine performance is vital for both electricity generation and heat recovery.

Related Products/Series

The Woodward 8400-series broadly covers ProAct™ Digital Controls. Other related part numbers and components in the ProAct ecosystem include:

- 8400-059: Another ProAct Digital Speed Control, often listed as a direct replacement or updated version for earlier models like 8400-010. The 8400-061 might represent a specific feature set or revision distinct from the 8400-059, perhaps related to fuel limiting functionalities often grouped with 8400-055.

- 8400-055: Often identified as a ProAct Fuel Limit module. The 8400-061 and 8400-055 are sometimes listed together, indicating complementary functions or alternative configurations for fuel management.

- 8400-010: An older ProAct Model II Speed Control that has seen newer revisions like the 8400-059.

- 8400-015: ProAct mA Control, designed for actuators that accept a 0–200 mA output signal.

- ProAct Actuators: Such as ProAct I or ProAct II actuators (e.g., 8256-series), which are the mechanical interface controlled by units like the 8400-061.

- ProAct Drivers: Intermediate modules (e.g., 8400-706, 8400-703) that provide power and interface between the ProAct controller and actuator in certain system architectures.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922