الوصف

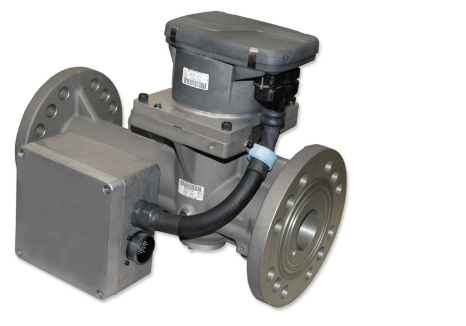

WOODWARD 8407-512: TecJet™ 50 Plus Gaseous Fuel Metering Valve (Inactivated)

The Woodward 8407-512 is a specific part number for a TecJet™ 50 Plus Gaseous Fuel Metering Valve. This integrated valve and actuator system was designed for precise fuel flow regulation in natural gas and dual-fuel engines.

Product Overview

- Product Type: Gaseous Fuel Metering Valve / Integrated Valve and Actuator

- Manufacturer: Woodward

- Series: TecJet™ 50 Plus

- Function: Precisely controls the mass flow rate of gaseous fuels (such as natural gas, biogas, LPG) to an internal combustion engine. It receives a fuel rate demand signal from a main engine control system and accurately adjusts its internal valve position to deliver the exact required flow.

- Key Features:

- Integrated Design: Combines the valve and the electronic actuator into a single unit, simplifying installation and wiring.

- Digital Compensation: Features onboard electronics that automatically compensate for variations in gas pressure and temperature, ensuring accurate mass flow metering regardless of fluctuating gas supply conditions. This is crucial for optimal engine performance, efficiency, and emissions control.

- High Response: Engineered for fast and precise adjustments to fuel flow commands.

- Feedback Sensors: Incorporates internal sensors to continuously monitor critical parameters such as fuel pressure, temperature, and valve pressure differential.

- Valve Size: The “50 Plus” indicates a nominal valve size, likely around 50 mm.

- Generation Status: This is a non-RoHS compliant version from an older generation of TecJet valves.

Detailed Description

The Woodward TecJet™ 50 Plus valve, including the 8407-512, provided effective fuel control for gaseous and dual-fuel engines. Its integrated design and digital compensation capabilities were key to its operation.

Key characteristics of the 8407-512:

- Precise Fuel Metering: The valve dynamically adjusted fuel flow based on real-time engine load and speed demands, helping to maintain the optimal air/fuel ratio for efficient combustion, reduced fuel consumption, and lower emissions.

- Closed-Loop Control: Integrated electronics and sophisticated control algorithms, coupled with internal feedback sensors, allowed for precise closed-loop control of fuel delivery, offering accuracy and stability.

- Robust Construction: Built to endure the demanding conditions of engine environments, including high levels of vibration and wide operating temperature extremes.

- Communication: Communication to the TecJet valve typically occurred over a CAN link, where the engine control system sent demand signals. This particular part number would have been designed for a specific protocol, though explicit details for the 8407-512 are not commonly available in public summaries.

Applications

The Woodward 8407-512 TecJet™ 50 Plus valve would have been applied in various engine systems running on gaseous fuels:

- Natural Gas Engines: Used on four-cycle, turbocharged engines for power generation, marine propulsion, and industrial applications.

- Dual-Fuel Engines: Where engines could switch between or combine liquid and gaseous fuels.

- CHP (Combined Heat and Power) Plants: Ensuring efficient and clean operation of gas engines.

- Compressor Stations: For gas engines driving compressors in pipeline and industrial processing applications.

Compatibility and Replacement Notes

When dealing with the Woodward 8407-512, it’s crucial to understand its current status:

- Obsolescence: As of current information, the 8407-512 is explicitly listed as a non-RoHS, older generation part number that has been inactivated. This means direct sales and repair options are discontinued.

- Replacement: The official replacement for the 8407-512 is the 8407-601.

- Backward Compatibility: The 8407-601 is a Generation II (Gen II) TecJet 52 model (note the name change from 50 Plus to 52 for the newer generation, though functionally it’s a direct successor). Gen II TecJet valves are designed to be 100% backward compatible with older TecJet 50 Plus and TecJet 52 valves (including the 8407-512). This means you should be able to replace an 8407-512 with an 8407-601 without requiring engine recalibration, thanks to factory flow testing and robust design.

- Protocol Match: The 8407-601 is designed to maintain communication compatibility with the systems that used the 8407-512, ensuring a smooth upgrade path.

If you are looking to replace an existing 8407-512, the 8407-601 is the recommended modern equivalent from Woodward.

WOODWARD 8407-512: TecJet™ 50 Plus Gaseous Fuel Metering Valve (Inactivated)

The Woodward 8407-512 is a specific part number for a TecJet™ 50 Plus Gaseous Fuel Metering Valve. This integrated valve and actuator system was designed for precise fuel flow regulation in natural gas and dual-fuel engines.

Product Overview

- Product Type: Gaseous Fuel Metering Valve / Integrated Valve and Actuator

- Manufacturer: Woodward

- Series: TecJet™ 50 Plus

- Function: Precisely controls the mass flow rate of gaseous fuels (such as natural gas, biogas, LPG) to an internal combustion engine. It receives a fuel rate demand signal from a main engine control system and accurately adjusts its internal valve position to deliver the exact required flow.

- Key Features:

- Integrated Design: Combines the valve and the electronic actuator into a single unit, simplifying installation and wiring.

- Digital Compensation: Features onboard electronics that automatically compensate for variations in gas pressure and temperature, ensuring accurate mass flow metering regardless of fluctuating gas supply conditions. This is crucial for optimal engine performance, efficiency, and emissions control.

- High Response: Engineered for fast and precise adjustments to fuel flow commands.

- Feedback Sensors: Incorporates internal sensors to continuously monitor critical parameters such as fuel pressure, temperature, and valve pressure differential.

- Valve Size: The “50 Plus” indicates a nominal valve size, likely around 50 mm.

- Communication Protocol: The 8407-512 is known to work with the Woodward EGS-02/E6 gas metering valve system.

- Generation Status: This is a non-RoHS compliant version from an older generation of TecJet valves.

Detailed Description

The Woodward TecJet™ 50 Plus valve, including the 8407-512, provided effective fuel control for gaseous and dual-fuel engines. Its integrated design and digital compensation capabilities were key to its operation.

Key characteristics of the 8407-512:

- Precise Fuel Metering: The valve dynamically adjusted fuel flow based on real-time engine load and speed demands, helping to maintain the optimal air/fuel ratio for efficient combustion, reduced fuel consumption, and lower emissions.

- Closed-Loop Control: Integrated electronics and sophisticated control algorithms, coupled with internal feedback sensors, allowed for precise closed-loop control of fuel delivery, offering accuracy and stability.

- Robust Construction: Built to endure the demanding conditions of engine environments, including high levels of vibration and wide operating temperature extremes.

- Communication: Communication to the TecJet valve typically occurred over a CAN link, where the engine control system sent demand signals. For the 8407-512, this was specifically compatible with the EGS-02/E6 protocol, ensuring seamless integration with those Woodward control platforms.

Applications

The Woodward 8407-512 TecJet™ 50 Plus valve would have been applied in various engine systems running on gaseous fuels:

- Natural Gas Engines: Used on four-cycle, turbocharged engines for power generation, marine propulsion, and industrial applications.

- Dual-Fuel Engines: Where engines could switch between or combine liquid and gaseous fuels.

- CHP (Combined Heat and Power) Plants: Ensuring efficient and clean operation of gas engines.

- Compressor Stations: For gas engines driving compressors in pipeline and industrial processing applications.

Compatibility and Replacement Notes

When dealing with the Woodward 8407-512, it’s crucial to understand its current status:

- Obsolescence: The 8407-512 is explicitly listed as a non-RoHS, older generation part number that has been inactivated. This means direct sales and repair options are discontinued.

- Replacement: The official replacement for the 8407-512 is the 8407-601.

- Backward Compatibility: The 8407-601 is a Generation II (Gen II) TecJet 52 model (note the name change from 50 Plus to 52 for the newer generation, though functionally it’s a direct successor). Gen II TecJet valves are designed to be 100% backward compatible with older TecJet 50 Plus and TecJet 52 valves (including the 8407-512). This means you should be able to replace an 8407-512 with an 8407-601 without requiring engine recalibration, thanks to factory flow testing and robust design.

- Protocol Match: The 8407-601 is designed to maintain communication compatibility with the systems that used the 8407-512 (e.g., EGS-02/E6), ensuring a smooth upgrade path.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922