الوصف

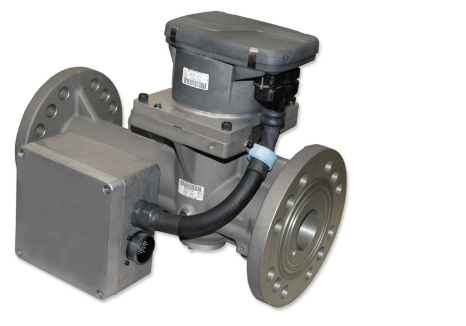

The Woodward 8407-603 is a specific part number for a TecJet™ 52 Gaseous Fuel Metering Valve. It’s a critical component in advanced engine control systems, particularly for natural gas or dual-fuel engines.

WOODWARD 8407-603: TecJet™ 52 Gaseous Fuel Metering Valve

The Woodward 8407-603 is an integrated, digitally-compensated control valve and actuator system designed specifically for precisely regulating and metering the flow of gaseous fuels (like natural gas, LPG, etc.) to an engine. It’s part of the TecJet™ family, which is known for its accuracy, responsiveness, and ability to handle various gas qualities in demanding applications.

Product Overview

- Product Type: Gaseous Fuel Metering Valve / Integrated Valve and Actuator

- Manufacturer: Woodward

- Series: TecJet™ 52

- Function: Controls the amount of gaseous fuel delivered to an internal combustion engine. It receives a fuel rate demand signal from a higher-level engine control system (e.g., a Woodward EGS-02, GECM, or other engine control module) and precisely adjusts its internal valve position to deliver the required mass flow of fuel.

- Key Features:

- Integrated Design: Combines the valve and the electronic actuator into a single unit, simplifying installation, reducing wiring complexity, and improving overall system reliability.

- Digital Compensation: Features onboard electronics that compensate for variations in gas pressure and temperature. This ensures accurate mass flow metering of fuel regardless of fluctuating gas supply conditions, which is crucial for optimal engine performance, efficiency, and emissions control.

- High Response: Engineered for fast and precise adjustments to fuel flow, enabling tight engine control dynamics and excellent transient response.

- Feedback Sensors: Incorporates internal sensors to monitor critical parameters such as fuel pressure, temperature, and valve pressure differential. This data is used for internal control loops and can often be communicated back to the main engine controller.

- Communication Protocol: The 8407-603 is specifically noted to operate with the GECM (Gas Engine Control Module) exclusive protocol or for Jenbacher (exclusive) applications. This is a key distinction for compatibility with the overall engine control system.

- Generation: This particular part number is a Generation II (Gen II) TecJet 52, which generally indicates it’s a newer version than some older models, potentially featuring RoHS compliance and other enhancements.

Detailed Description

The Woodward TecJet™ 52 valve, including the 8407-603, is vital for modern gaseous and dual-fuel engines, enabling them to operate efficiently while meeting increasingly stringent emission standards.

Key characteristics of the 8407-603:

- Precise Fuel Metering: The valve dynamically adjusts the fuel flow based on engine load and speed demands. By accurately controlling the fuel quantity, it helps maintain the optimal air/fuel ratio for efficient combustion, which minimizes fuel consumption and reduces harmful emissions.

- Closed-Loop Control: The integrated electronics and sophisticated control algorithms, coupled with internal feedback sensors, allow for precise closed-loop control of fuel delivery. This provides excellent accuracy, stability, and repeatability.

- Robust Construction: Built to withstand the harsh conditions of engine environments, including high levels of vibration, wide operating temperature extremes, and exposure to various gaseous fuels.

- Protocol Specificity: The 8407-603’s compatibility with the GECM or Jenbacher exclusive protocol is crucial. This means it’s designed to communicate and integrate seamlessly within these specific control architectures. Other TecJet 52 variants might use different protocols (e.g., EGS-01, EGS-02, or CANopen), so ensuring the correct protocol match is essential for proper system operation.

- Benefits: By enabling such precise and compensated fuel control, TecJet valves contribute significantly to:

- Improved engine efficiency and reduced operational costs.

- Lower exhaust emissions (e.g., NOx, CO, unburned hydrocarbons), aiding in environmental compliance.

- Enhanced engine transient response, allowing for quicker and smoother reactions to load changes.

- Overall improved reliability and simplified engine tuning and calibration.

Applications

The Woodward 8407-603 TecJet™ 52 valve is widely applied in various engine systems that run on gaseous fuels, particularly those leveraging Woodward’s GECM or designed for Jenbacher engines:

- Natural Gas Engines: Used on four-cycle, turbocharged engines for power generation (generator sets), marine propulsion, and industrial applications.

- Dual-Fuel Engines: Where engines can switch between or combine liquid and gaseous fuels.

- CHP (Combined Heat and Power) Plants: Ensuring efficient and clean operation of gas engines that provide both electricity and heat.

- Compressor Stations: For gas engines driving compressors in pipeline and industrial processing applications.

Compatibility and Replacement Notes

When dealing with TecJet 52 valves, especially the 8407-603, it’s vital to consider:

- Protocol Match: The primary consideration for replacement is always the communication protocol. An 8407-603 (GECM/Jenbacher protocol) cannot be simply swapped with a TecJet 52 using, for example, the EGS-01 or EGS-02 protocol, unless the entire control system is being upgraded or reconfigured.

- Generation Differences: As a Gen II unit, it often offers improvements over older “non-RoHS” TecJet 52 models. While functionally compatible in terms of the task it performs, always verify any specific electrical or physical differences with Woodward documentation if replacing an older version.

- Obsolescence: While still in use, specific part numbers from older generations might eventually be superseded. Always check current availability and recommended replacements directly with Woodward or an authorized distributor.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922