الوصف

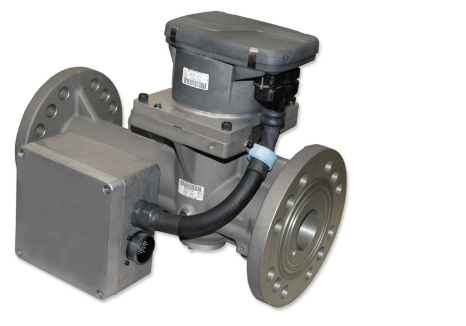

The Woodward 8407-647 is a specific part number for a TecJet™ 52 Gaseous Fuel Metering Valve. It’s an integrated, digitally-compensated control valve and actuator system designed for precise fuel flow regulation in natural gas and dual-fuel engines.

WOODWARD 8407-647: TecJet™ 52 Gaseous Fuel Metering Valve

The Woodward 8407-647 is a sophisticated, all-in-one component that combines a fuel valve and its electronic actuator. It is part of the TecJet™ 52 series, highly regarded for its accuracy and responsiveness in managing gaseous fuel delivery to engines.

Product Overview

- Product Type: Gaseous Fuel Metering Valve / Integrated Valve and Actuator

- Manufacturer: Woodward

- Series: TecJet™ 52

- Function: Precisely controls the mass flow rate of gaseous fuels (like natural gas, biogas, LPG, or even low-BTU specialty gases) to an internal combustion engine. It receives a fuel rate demand signal from a main engine control system and accurately adjusts its internal valve position to deliver the exact required flow.

- Key Features:

- Integrated Design: Combines the valve and the electronic actuator into a single unit, simplifying installation, reducing wiring complexity, and enhancing reliability.

- Digital Compensation: Features onboard electronics that automatically compensate for variations in gas pressure and temperature. This ensures accurate mass flow metering of fuel regardless of fluctuating gas supply conditions, which is crucial for optimal engine performance, efficiency, and emissions control.

- High Response: Engineered for fast and precise adjustments to fuel flow commands, allowing the engine to accept large load steps without losing speed.

- Feedback Sensors: Incorporates internal sensors to continuously monitor critical parameters such as fuel pressure, temperature, and valve pressure differential. This data is used for internal control loops and can be communicated to the main engine controller.

- High Turn-down Ratio: This allows one TecJet model to be used across a wide range of fuel flow requirements and potentially for a complete engine family.

- Valve Size: The “52” in TecJet 52 indicates a nominal valve size of 52 mm.

- Input Voltage Range: 18–32 Vdc.

- Current Consumption: Typically around 1 A @ 24 Vdc steady state, with transients up to 3.75 A.

- Temperature Ranges:

- Steady State Ambient: –20 to +85 °C (–4 to +185 °F)

- Long Term Storage: –40 to +40 °C (–40 to +104 °F)

- Typical Power Range: Applicable for stationary applications within a power range of 210–800 kW for low-BTU specialty gas and 500–1500 kW for pipeline-quality natural gas (this range is dependent on other factors).

Detailed Description

The Woodward TecJet™ 52 valve, including the 8407-647, is a vital component for modern gaseous and dual-fuel engines. It enables them to operate efficiently, with high performance, and meet increasingly stringent emission standards.

Key characteristics of the 8407-647:

- Precise Fuel Metering: The valve dynamically adjusts fuel flow based on real-time engine load and speed demands. By accurately controlling the fuel quantity, it helps maintain the optimal air/fuel ratio for efficient combustion, which minimizes fuel consumption and reduces harmful emissions.

- Closed-Loop Control: The integrated electronics and sophisticated control algorithms, coupled with internal feedback sensors, allow for precise closed-loop control of fuel delivery. This provides excellent accuracy, stability, and repeatability, crucial for consistent engine operation.

- Robust Construction: Built to endure the demanding conditions of engine environments, including high levels of vibration, wide operating temperature extremes, and continuous exposure to various gaseous fuels.

- Communication Protocol: While the specific protocol for the 8407-647 isn’t explicitly listed in the immediate search results, TecJet 52 valves generally communicate via a CAN link (Controller Area Network) to a separate engine control system. Common protocols used with TecJet 52 include EGS-01, EGS-02/E6, GECM, or CANopen, depending on the specific variant and the overall control system. To confirm the exact protocol for 8407-647, you would typically need to consult Woodward’s specific product documentation or contact their technical support.

- Benefits: By enabling such precise and compensated fuel control, TecJet valves significantly contribute to:

- Improved engine efficiency and reduced operational costs.

- Lower exhaust emissions (e.g., NOx, CO, unburned hydrocarbons), aiding in environmental compliance.

- Enhanced engine transient response, allowing for quicker and smoother reactions to load changes.

- Overall improved reliability and simplified engine tuning and calibration.

Applications

The Woodward 8407-647 TecJet™ 52 valve is widely applied in various engine systems that run on gaseous fuels:

- Natural Gas Engines: Used on four-cycle, turbocharged engines for power generation (generator sets), marine propulsion, and industrial applications.

- Dual-Fuel Engines: Where engines can switch between or combine liquid and gaseous fuels.

- CHP (Combined Heat and Power) Plants: Ensuring efficient and clean operation of gas engines that provide both electricity and heat.

- Compressor Stations: For gas engines driving compressors in pipeline and industrial processing applications.

Compatibility and Replacement Notes

When dealing with TecJet 52 valves, it’s vital to consider:

- Generation: The TecJet 52 has gone through different generations (e.g., Gen I, Gen II). Gen II (RoHS compliant) variants are often backward compatible with non-RoHS versions, but it’s always best to verify with Woodward documentation. As of September 30, 2025 (the current date is July 30, 2025), non-RoHS versions are reaching product inactivation, with limited repair and sales.

- Protocol Match: The primary consideration for replacement is always the communication protocol used by your engine’s main control system. Ensure the replacement TecJet valve supports the identical protocol as the existing one.

- Flow Testing: Newer Gen II TecJet valves are designed to be “drop-in replacements” and flow testing is often performed during manufacturing to ensure the engine does not need to be recalibrated when previous models are replaced.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922