الوصف

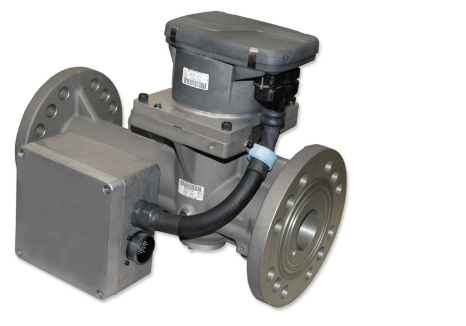

The Woodward 8407-647 is a specific part number for a TecJet™ 52 Gaseous Fuel Metering Valve. This integrated valve and actuator system is crucial for precisely controlling the flow of gaseous fuels in various engine applications.

WOODWARD 8407-647: TecJet™ 52 Gaseous Fuel Metering Valve

The Woodward 8407-647 is a sophisticated, all-in-one component that combines a fuel valve with its electronic actuator and integrated intelligence. It’s part of the TecJet™ 52 series, highly regarded for its accuracy and responsiveness in managing gaseous fuel delivery to engines.

Product Overview

- Product Type: Gaseous Fuel Metering Valve / Integrated Valve and Actuator

- Manufacturer: Woodward

- Series: TecJet™ 52

- Function: Precisely controls the mass flow rate of gaseous fuels (such as natural gas, biogas, LPG, or low-BTU specialty gases) to an internal combustion engine. It receives a fuel rate demand signal from a main engine control system and accurately adjusts its internal valve position to deliver the exact required flow.

- Key Features:

- Integrated Design: Combines the valve and the electronic actuator into a single unit, simplifying installation, reducing wiring complexity, and enhancing reliability.

- Digital Compensation: Features onboard electronics that automatically compensate for variations in gas pressure and temperature. This ensures accurate mass flow metering regardless of fluctuating gas supply conditions, which is crucial for optimal engine performance, efficiency, and emissions control.

- High Response: Engineered for fast and precise adjustments to fuel flow commands, allowing the engine to accept large load steps without losing speed.

- Feedback Sensors: Incorporates internal sensors to continuously monitor critical parameters such as fuel pressure, temperature, and valve pressure differential. This data is used for internal control loops and can be communicated to the main engine controller.

- High Turn-down Ratio: This allows one TecJet model to be used across a wide range of fuel flow requirements, potentially for a complete engine family. The TecJet 52 Gen II, which the 8407-647 is, can have a turndown ratio of 110:1.

- Valve Size: The “52” in TecJet 52 indicates a nominal valve size of 52 mm.

- Input Voltage Range: 18–32 Vdc.

- Current Consumption: Typically around 1 A @ 24 Vdc steady state, with transients up to 3.75 A.

- Temperature Ranges:

- Steady State Ambient: –20 to +85 °C (–4 to +185 °F)

- Long Term Storage: –40 to +40 °C (–40 to +104 °F)

- Weight: Approximately 17 kg (38 lb).

- Protection Class: IP64 (some Gen II versions are NEMA 4 watertight).

- Communication Protocol: The TecJet 52 series (including the 8407-647) primarily uses a CAN (Controller Area Network) link for communication with a separate engine control system. While specific part numbers within the TecJet 52 family can be configured for different higher-layer protocols (like EGS-01, EGS-02/E6, GECM, or CANopen), the 8407-647 is listed as a Generation II (Gen II) model. These Gen II models are designed to be 100% backwards compatible with older TecJet 50 Plus and TecJet 52 valves.

Detailed Description

The Woodward TecJet™ 52 valve, including the 8407-647, is an essential component for modern gaseous and dual-fuel engines, enabling them to operate efficiently, with high performance, and meet increasingly stringent emission standards.

Key characteristics of the 8407-647:

- Precise Fuel Metering: The valve dynamically adjusts fuel flow based on real-time engine load and speed demands. By accurately controlling the fuel quantity, it helps maintain the optimal air/fuel ratio for efficient combustion, which minimizes fuel consumption and reduces harmful emissions.

- Closed-Loop Control: The integrated electronics and sophisticated control algorithms, coupled with internal feedback sensors, allow for precise closed-loop control of fuel delivery. This provides excellent accuracy, stability, and repeatability, crucial for consistent engine operation.

- Robust Construction: Built to endure the demanding conditions of engine environments, including high levels of vibration (exceeds WGC RV2), wide operating temperature extremes, and continuous exposure to various gaseous fuels.

- Communication: Communication to the TecJet valve occurs over a CAN link, where the engine control system sends demand signals. The TecJet then uses its internal logic and sensor feedback to achieve the commanded flow.

- Gen II Enhancements: As a Gen II model, the 8407-647 likely benefits from improvements such as:

- Improved dynamic response and repeatability.

- Lower closed-flow leak, allowing for better startup and low-load control.

- Enhanced environmental sealing (e.g., NEMA 4 watertight).

- More robust design for specialty gases, with sealed bearings.

- Lighter weight compared to older versions.

Applications

The Woodward 8407-647 TecJet™ 52 valve is widely applied in various engine systems that run on gaseous fuels:

- Natural Gas Engines: Used on four-cycle, turbocharged engines for power generation (generator sets), marine propulsion, and industrial applications.

- Dual-Fuel Engines: Where engines can switch between or combine liquid and gaseous fuels.

- CHP (Combined Heat and Power) Plants: Ensuring efficient and clean operation of gas engines that provide both electricity and heat.

- Compressor Stations: For gas engines driving compressors in pipeline and industrial processing applications.

- Engines with Variable Gas Qualities: Its digital compensation for pressure and temperature makes it suitable for applications with varying fuel gas compositions or conditions.

Compatibility and Replacement Notes

When dealing with TecJet 52 valves, especially the 8407-647:

- Generation Transition: The 8407-647 is a Generation II TecJet 52. Woodward has been phasing out older, non-RoHS compliant versions, and the Gen II models are designed as direct, 100% backward-compatible replacements. This means that if you are replacing an older TecJet 52 (which may have a different, older part number that maps to the 8407-647 as its replacement), the 8407-647 should function seamlessly without requiring engine recalibration due to factory flow testing.

- Protocol: While the general communication is CAN, confirm the specific higher-layer protocol (e.g., J1939, or Woodward’s proprietary EGS-01/EGS-02) if you’re integrating with a new control system, although Gen II models often support multiple common protocols.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922