الوصف

The Woodward 8440-2080 is a specific part number for an easYgen-2000 Series genset controller, typically known as the easYgen-2300-5/P1. This robust controller was designed for comprehensive management and protection of generator sets in a range of applications, including standalone operation and load sharing within a power system.

WOODWARD 8440-2080: easYgen-2300-5/P1 Genset Controller

The Woodward 8440-2080 easYgen-2300-5/P1 is a member of Woodward’s easYgen-2000 series, a line of powerful and versatile controls for generator set applications. It’s engineered to provide flexible control and protection for both the engine and the generator, with advanced communication capabilities.

Product Overview

- Product Type: Generator Set Controller (Genset Controller)

- Manufacturer: Woodward

- Series: easYgen-2000 Series (specifically easYgen-2300-5/P1)

- Function: This controller provides extensive control, monitoring, and protection functions for generator sets. It’s capable of managing engine start/stop sequences, generator voltage and frequency, and monitoring numerous parameters for both the engine and the generator. The “P1” designation often indicates a specific package or feature set, typically including capabilities for single-unit operations or basic load sharing.

- Key Features:

- Comprehensive Control: Manages engine operation (start/stop logic for diesel/gas engines, pre-glow/purge control, warm-up control) and generator output (voltage, frequency).

- Display: Features an integrated backlit LCD for displaying status indicators, operational data, and alarm messages.

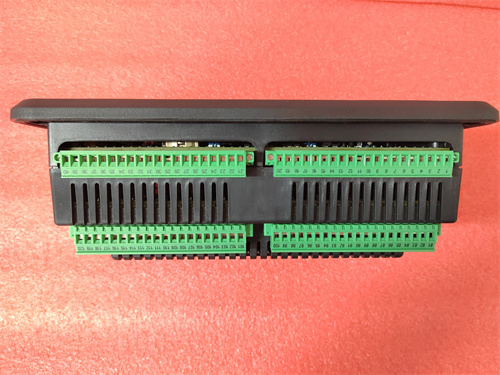

- Extensive I/O: Equipped with numerous configurable terminals for connecting a wide range of sensors and actuators, allowing for flexible system integration. It offers features like resistive current voltage sensing and an analog input of 0-20 mA.

- Electronic Engine Support: Capable of communicating directly with electronic engine ECUs (Electronic Control Units) via CAN bus (J1939), enabling detailed monitoring and control of engine parameters.

- Generator Metering: Provides accurate measurement of 3-phase generator voltage, current, power (kW, kVA, kVAr), and frequency.

- Protection Functions: Offers comprehensive protection for both the engine (e.g., overspeed, low oil pressure, high temperature) and the generator (e.g., over/under voltage, over/under frequency, overcurrent, reverse power, phase sequence).

- Advanced Communication: Features advanced interface capabilities, including:

- CANopen: For peer-to-peer load sharing among multiple gensets (up to 16 units in island operation).

- J1939: For engine ECU communication.

- Modbus RTU: For integration with PLCs, HMIs, and SCADA systems.

- Modem support: For remote control and programming using Woodward’s ToolKit software.

- Event Log: Stores a detailed event log with a real-time clock for diagnostic purposes and troubleshooting.

- Configurability: Highly configurable via PC software (such as Woodward’s ToolKit-SC) or directly from the front panel, with multi-level password protection.

- Load-Dependent Start/Stop: Integrated programming to optimize fuel efficiency by bringing gensets on- and off-line based on changing load demands, even with mixed-sized engines.

Detailed Description

The easYgen-2000 series, including the 8440-2080, was a core product in Woodward’s portfolio for sophisticated generator control. These controllers are recognized for their robust design and broad feature set, making them suitable for demanding industrial and commercial applications. They excelled in managing individual generator sets and could also be integrated into more complex systems for synchronized load sharing among multiple gensets, whether in island mode or paralleling with the utility grid.

It’s important to note that some units from the easYgen-2000 series, including the 8440-2080, were identified in Woodward Service Bulletin 37987 (Revision A, 06/2024) for potential LCD display performance issues (e.g., blank screen, abnormal contrast, flickering, or non-working keypads). This issue was traced to a specific non-standard soldering process and primarily affected the HMI, not the core control functionality. In some cases, cleaning corrosion on display terminals could resolve the issue.

Applications

The Woodward 8440-2080 easYgen-2000 Series controller was commonly used in a wide array of power generation applications, including:

- Standby/Emergency Power Systems: Controlling gensets that provide backup power for commercial buildings, industrial facilities, and critical infrastructure during grid outages, often with Automatic Mains Failure (AMF) functionality.

- Prime Power Applications: Managing gensets that serve as the primary power source in remote or off-grid locations.

- Peak Shaving and Import/Export Control: Optimizing energy costs by running gensets during peak demand periods or controlling power flow to and from the utility.

- Co-generation / CHP (Combined Heat and Power): Integrating gensets into systems that produce both electricity and useful heat.

- Load Sharing Applications: Synchronizing and sharing load among multiple generator sets in island or parallel-to-grid operations.

Obsolescence and Replacement Options

It’s crucial to be aware of the current status of the 8440-2080:

- Obsolescence (End-of-Life): The easYgen-2000 series, including the 8440-2080, has been officially designated as inactivated (End-of-Life) by Woodward. This means that direct sales and new production of this specific part number are discontinued. This decision is primarily due to the obsolescence of internal components. A Last Time Buy (LTB) period for these controls concluded on January 23, 2015, with final shipments occurring by April 22, 2015.

- Limited Support: While some third-party repair and refurbishment services may still offer support for these units, direct support and new unit availability from Woodward are severely limited. Any repair services provided directly by Woodward for these older models are typically on a declining support schedule, with repairs based on parts availability becoming the norm.

- Recommended Replacements: Woodward has introduced newer, more advanced generations of genset controllers to replace the easYgen-2000 series. The recommended modern replacements typically include:

- easYgen-3000XT Series: This series is the direct successor and offers enhanced features, improved connectivity (including robust Ethernet), advanced control algorithms, and a more modern user interface. It’s designed to handle a wide range of single-unit and paralleling applications, effectively covering and expanding upon the capabilities of the easYgen-2000 series.

- easYgen-1000 Series (newer variants): For simpler single-unit AMF applications that don’t require extensive paralleling features, newer models within the easYgen-1000 series might also be suitable, depending on the specific feature set required.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922