الوصف

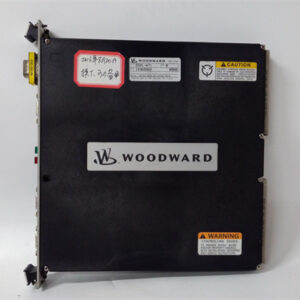

The WOODWARD 9904-814 is a mechanical-hydraulic speed droop governor designed for controlling steam turbines. It’s often referenced in relation to the older TG-13 governors, as it serves as a replacement in certain applications.

WOODWARD 9904-814: Mechanical-Hydraulic Speed Droop Governor

The WOODWARD 9904-814 is a specialized control device vital for the reliable operation of small to medium-sized steam turbines, particularly those driving pumps, compressors, or generators where precise, constant-speed (isochronous) operation isn’t a strict requirement.

Product Overview

The 9904-814 is a self-contained, mechanical-hydraulic governor. Its primary function is to control turbine speed by sensing the turbine rotor speed and comparing it to an internal setpoint. It then adjusts the turbine’s governor valve to control the inlet steam flow, thereby regulating the turbine’s speed.

- Product Type: Mechanical-Hydraulic Speed Droop Governor

- Manufacturer: Woodward

- Application: Small to medium steam turbines (e.g., driving pumps, compressors, generators).

- Key Feature: Speed droop control (not isochronous).

- Drive Shaft Rotation: Counterclockwise.

- Output: 16 N·m (12 ft-lb) counterclockwise rotary output terminal shaft.

- Speed Set Range: Typically 1200-2400 rpm (may vary slightly by specific configuration).

- Environmental Certification: Designed for hazardous locations (HAZLOC) and ATEX certified.

Detailed Product Description

The WOODWARD 9904-814 is a robust and cost-effective solution for steam turbine speed control. It’s often cited as a modern equivalent or replacement for older TG-13 governors, offering similar functionality with potentially updated features or certifications.

Here’s a breakdown of its features and how it functions:

- Mechanical-Hydraulic Operation: This governor is a self-contained unit that uses an integrated driveshaft-driven ball head assembly to sense turbine speed. An integrated driveshaft-driven oil pump generates the necessary hydraulic pressure to create the force required to move and control the turbine’s governor valve. This mechanical-hydraulic design makes it inherently robust and less reliant on external electronic components for core speed sensing and actuation.

- Speed Droop Control: Unlike isochronous governors that strive for absolute constant speed, the 9904-814 operates on a speed droop principle. This means that as the load on the turbine increases, its speed will slightly decrease (or “droop”) proportionally. This characteristic is often desirable in applications where load sharing among multiple prime movers is needed, or where a slight speed variation under load changes is acceptable.

- Direct Turbine Connection: The governor directly couples to the steam turbine’s rotor or an auxiliary shaft to sense the turbine’s speed. Its rotary output terminal shaft directly connects to the turbine’s governor valve, precisely controlling the inlet steam flow.

- Rugged Construction: Built for harsh industrial environments, the 9904-814 features weatherproof construction and a self-contained sump. Its design is suitable for operation in demanding conditions, including those found in HAZLOC and ATEX certified areas, indicating its suitability for potentially explosive atmospheres.

- Typical Speed and Output: The governor typically has a screw speed set range of 1200-2400 rpm. Its output terminal shaft delivers a significant 16 N·m (12 ft-lb) of rotary work capacity, which is sufficient to operate various turbine governor valves. The counterclockwise drive shaft rotation is a specific design consideration for compatibility with certain turbine configurations.

The 9904-814 provides a reliable and cost-effective solution for applications where a robust, self-contained mechanical-hydraulic governor with speed droop characteristics is required for steam turbine control.

Technical Specifications (General)

Typical Applications

The WOODWARD 9904-814 is primarily used in industrial settings that employ small to medium steam turbines for mechanical drive or power generation, especially where constant-speed operation isn’t mandatory:

- Pumps: Controlling steam turbines that drive process pumps in various industries.

- Compressors/Turboexpanders: Regulating the speed of steam turbines used to drive compressors in chemical plants, refineries, or gas processing facilities.

- Generators: Controlling the speed of steam turbines connected to generators for power generation, often where they might operate in parallel with other power sources or grid connections that can absorb speed droop.

- Force and Induced Draft Fans: Managing steam turbines that power large industrial fans in power plants or other heavy industries.

- Shipbuilding Industry: Used in marine applications for controlling steam turbine-driven auxiliary machinery.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922