الوصف

The WOODWARD 9907-1233 is not a fuel metering valve like the GS series. Instead, it is a Current to Pressure Converter, Generation II (CPC-II). This is an electrohydraulic pressure-regulating valve control, primarily designed for use in positioning single-acting steam turbine valve servos.

WOODWARD 9907-1233: CPC-II (Current to Pressure Converter, Generation II)

The WOODWARD 9907-1233 CPC-II is a high-accuracy, high-resolution device critical for the precise control of steam turbine valves, which in turn regulates turbine speed and load. Its advanced design makes it highly suitable for demanding industrial environments.

Product Overview

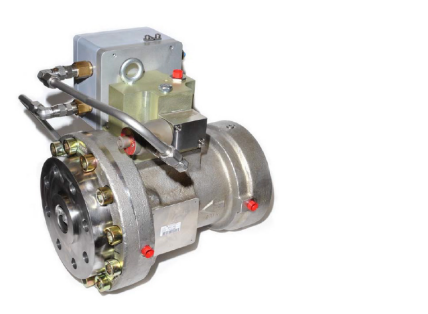

The CPC-II is a sophisticated electrohydraulic device that translates an electrical control signal (typically a 4–20 mA pressure demand signal) into a precise hydraulic oil pressure output. This output pressure is then used to accurately position single-acting steam turbine governor-valves.

- Product Type: Current to Pressure Converter, Electrohydraulic Pressure-Regulating Valve Control

- Manufacturer: Woodward

- Part Number: 9907-1233

- Model Designation: CPC-II (Generation II)

- Key Specifications (based on Woodward’s product documentation for CPC-II):

- Input Signal: Accepts a 4–20 mA pressure demand signal.

- Output: Precisely controls oil pressure to position single-acting steam turbine governor-valves.

- Internal Components: Consists of a valve-actuator assembly, a highly accurate internal pressure sensor, and an electronic driver module with a PID controller.

- Design Features: Robust construction, corrosion-resistant materials, a single moving rotary valve, and a self-cleaning port design.

- Failsafe Mechanism: Includes an internal valve-return-spring that forces the CPC to a failsafe position (ports oil to drain) to safely close turbine control valves upon any internal unit failure (e.g., electrical input power failure, pressure sensor failure, processor failure).

- Redundancy: Can be applied in a dual-redundant fashion for applications requiring high reliability, simplifying system and control wiring.

- Documentation References: Product Spec: 03382, Manuals: 26307, 26335.

- Function: The CPC-II controls oil pressure by either porting supply-oil to its control-oil output port (which then acts on the turbine valve control oil) or by directing oil back to the system supply tank. Its specialized PID architecture allows for very stable pressure control during normal operation and rapid response (in milliseconds) to desired valve step changes during system or plant transients.

Detailed Product Description

The Woodward 9907-1233 CPC-II is engineered for high performance and exceptional reliability in steam turbine applications. Key features that highlight its capabilities include:

- Precise Fluid Pressure Control: Utilizes a highly accurate internal pressure sensor and a PID (Proportional-Integral-Derivative) controller to achieve extremely precise and stable control over the output oil pressure, directly impacting the steam turbine valve position.

- Stable & Linear Valve Control: Designed to provide stable and linear control of the turbine valve, which is essential for smooth turbine operation and accurate speed/load management. It often includes an internal valve linearization table to ensure optimal performance.

- Oil Contamination Resistance: The robust design, including a strong actuator, corrosion-resistant materials, a single moving rotary valve, and a self-cleaning port design, makes it highly resilient to dirty or contaminated oil environments. This significantly reduces maintenance needs and improves reliability in challenging applications.

- Rapid Response: The special PID architecture enables the CPC-II to perform very stable pressure control under normal conditions and to respond in milliseconds to large, desired valve step changes during system or plant transients, crucial for maintaining control during dynamic events.

- High Reliability and Redundancy Options: The inherent reliability of the design is further enhanced by the option for dual-redundant configurations, providing a fault-tolerant solution for critical applications. The failsafe mechanism ensures turbine safety in the event of an internal unit failure.

- Integration: It’s designed for seamless integration with Woodward’s larger control systems, such as MicroNet or NetCon platforms, providing a comprehensive and coordinated turbine control solution.

Technical Specifications (for the 9907-1233 CPC-II)

Typical Applications

The WOODWARD 9907-1233 CPC-II is commonly found in critical industrial applications:

- Steam Turbine Control: Its primary use is in precisely controlling the governor valves of single-acting steam turbines, managing speed, load, and startup/shutdown sequences.

- Power Generation: Essential in power plants where steam turbines drive generators for electricity production.

- Industrial Processes: Used in various industrial processes where steam turbines provide mechanical drive for compressors, pumps, or other rotating equipment.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922