الوصف

The Woodward 9907-1289 is a specific part number for a ProAct™ Model I Speed Control with a High Output Sensor Circuit. This is an electronic control unit designed for precise speed management of various prime movers, particularly engines.

WOODWARD 9907-1289: ProAct™ Model I Speed Control (with High Output Sensor Circuit)

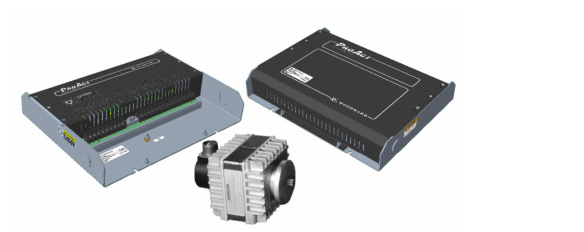

The Woodward 9907-1289 is a key component within the ProAct™ Digital Speed Control System. It acts as a dedicated speed controller, precisely regulating the speed of an engine or turbine by processing speed sensor signals and sending commands to a compatible actuator.

Product Overview

- Product Type: Digital Speed Control System / Speed Controller

- Manufacturer: Woodward

- Series: ProAct™ Model I Speed Control

- Function: Electronically monitors and regulates the speed of a prime mover (like a diesel or gas engine) by generating a control signal for an external actuator that manages fuel or air flow.

- Key Feature: Includes a High Output Sensor Circuit, indicating it’s designed to work effectively with speed sensors that provide a higher voltage output, ensuring robust signal integrity.

- Integration: It typically operates as part of a larger control system, receiving speed feedback (e.g., from a magnetic pickup) and sending a command to a Woodward ProAct actuator (e.g., ProAct I or ProAct II series).

Detailed Description

The ProAct™ Digital Speed Control systems are known for their advanced microprocessor-based control, delivering high precision, fast response, and reliable performance in challenging industrial environments. The 9907-1289 embodies these characteristics, serving as the “brain” for critical speed regulation tasks.

Key characteristics of the 9907-1289 include:

- Digital Control: Employs sophisticated digital algorithms to continuously compare the actual engine speed (sensed by an MPU) to a desired setpoint. It then calculates and outputs a precise command to maintain that speed.

- High Output Sensor Circuit: This feature signifies an enhanced input circuit capable of handling stronger signals from speed sensors. This can be beneficial in environments with electrical noise or for applications where the speed sensor generates a robust signal.

- Precise Speed Regulation: Crucial for applications demanding highly stable speed, such as generator sets that must maintain a constant electrical frequency, or industrial processes requiring consistent rotational speeds for equipment like pumps or compressors.

- Programmability: ProAct controllers are configurable using Woodward’s PC-based service tools. This allows users to fine-tune various parameters, including idle and rated speed setpoints, acceleration/deceleration ramps, specific fuel limiting curves (e.g., start fuel, maximum fuel, torque limit), and diagnostic settings.

- Robust Design: Built to withstand typical engine-room conditions, including vibrations, temperature fluctuations, and electromagnetic interference, ensuring long-term operational reliability.

- System Component: It’s important to note that this is typically the control module, not the actuator itself. It sends the command signal to a compatible ProAct electric actuator, which then mechanically positions the fuel or air control device on the engine.

Applications

The Woodward 9907-1289 (as part of the ProAct Model I system) is commonly used in:

- Power Generation: For speed and load control of diesel or gaseous engine-driven generator sets, ensuring stable electrical frequency and efficient power output.

- Industrial Engine Control: For a wide variety of industrial engines powering pumps, compressors, fans, and other machinery where accurate and responsive speed control is essential.

- Marine Propulsion: In some marine engine applications for managing main engine speed.

- Oil & Gas Industry: For engine control on gas compressors or pump drives.

Related Products/Series

The Woodward 9907-series contains various electronic control modules, and the 8400-series often refers to ProAct related components. Other related part numbers and components in the ProAct ecosystem include:

- 9907-1290: ProAct Model II Speed Control with High Output Sensor Circuit. This would be a later or more advanced version than the Model I (9907-1289).

- 8400-010: An older ProAct Model II Speed Control that some newer 8400-series controls replaced.

- 8400-059: A newer ProAct Digital Speed Control (often an update for the 8400-010).

- ProAct Actuators: Such as ProAct I or ProAct II actuators (e.g., 8256-series), which receive commands from the speed controller.

- ProAct Drivers: Intermediate modules (e.g., 8400-706, 8400-703) that provide power and interface between the ProAct controller and actuator in some system configurations.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922