الوصف

The search results indicate that WOODWARD 9907-2024 is a Load Sharing and Speed Control module. It appears to be part of the Woodward 2301A series of electronic controls.

Key details identified:

- Function: Primarily used for load sharing and speed control.

- Applications: Specifically noted for engines isolated with torque converters and split shaft gas turbines. The broader 2301A series is also used for generators driven by diesel or gasoline engines, or steam or gas turbines (“prime movers”).

- Control Modes: Capable of operating in either isochronous (constant speed) or droop mode.

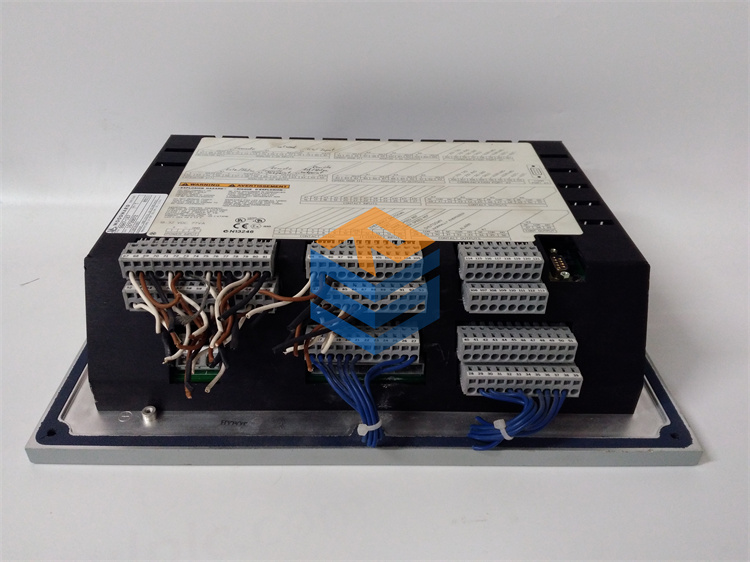

- Physical Characteristics: Housed in a sheet-metal chassis, consisting of a single printed circuit board with accessible potentiometers from the front.

- Power Supply: Models are available for low-voltage (20 to 40 Vdc) and high-voltage (90 to 150 Vdc or 88 to 132 Vac).

- Actuator Interface: Designed to work with a proportional actuator to position the fuel-metering device.

- Features: Includes 4-20 mA or 1-5 Vdc full authority speed setting, low and high-speed adjustments, and a start fuel limit with override.

- Environmental Considerations: Needs to be installed in an area that avoids vibrations, water exposure, high voltage, and electromagnetic interference.

It’s important to note that some search results for 9907-xxx models also point to other specific functionalities (e.g., CPC-II current to pressure converter, handheld programmers), but the most consistent description for 9907-2024 specifically is related to load sharing and speed control within the 2301A series.

WOODWARD 9907-2024: 2301A Electronic Load Sharing and Speed Control

Here’s a detailed, SEO-friendly product description for the WOODWARD 9907-2024, designed to be clear, engaging, and informative.

1. SEO-Optimized Headings

- WOODWARD 9907-2024: 2301A Electronic Load Sharing & Speed Control Module

- WOODWARD 9907-2024: Precision Speed & Load Management for Engines & Turbines

- Buy WOODWARD 9907-2024: Robust Control for Generator Sets & Industrial Prime Movers

- WOODWARD 9907-2024: Isochronous & Droop Mode Control for Optimal Performance

- WOODWARD 9907-2024: Reliable Electronic Governor for Split Shaft Gas Turbines

- WOODWARD 9907-2024: Advanced Fuel Limiting & Speed Adjustment Capabilities

- WOODWARD 9907-2024 Specifications: Versatile Control for Diverse Power Sources

- Installing WOODWARD 9907-2024: Ensuring Stable & Efficient Power Generation

- WOODWARD 9907-2024: Enhancing Prime Mover Control in Critical Applications

- Discover WOODWARD 9907-2024: Your Solution for Consistent Power Output

2. Product Overview

The WOODWARD 9907-2024 is an electronic control module from the renowned Woodward 2301A series, engineered for precise load sharing and speed control in various industrial applications. This robust controller is designed to manage the speed and load of diverse prime movers, including diesel engines, gas engines, steam turbines, and notably, split shaft gas turbines. It offers both isochronous (constant speed) and droop control modes, providing flexibility for single-prime-mover operations or synchronized generator sets. Housed in a durable sheet-metal chassis, the 9907-2024 ensures reliable performance in demanding industrial environments.

- Product Type: Electronic Load Sharing and Speed Control Module

- Series: Woodward 2301A

- Key Functions: Speed Control, Load Sharing

- Control Modes: Isochronous, Droop

- Applications: Diesel engines, gas engines, steam turbines, gas turbines (especially split shaft), and generator sets.

- Power: Available in low-voltage (20-40 Vdc) and high-voltage (90-150 Vdc or 88-132 Vac) models.

3. Detailed Product Description

In the realm of industrial power generation and mechanical drive applications, maintaining consistent speed and accurately sharing loads among multiple prime movers are crucial for efficiency, stability, and equipment longevity. Imagine a power plant where generators must operate seamlessly in parallel, or a gas compressor driven by a turbine that needs precise speed regulation under varying loads. This is where the WOODWARD 9907-2024 steps in, offering a time-tested and reliable solution for sophisticated prime mover control.

The WOODWARD 9907-2024 is a core component within the venerable Woodward 2301A series, a family of electronic controls renowned for their durability and performance in demanding environments. This particular model excels at providing precise control over the speed and load of engines and turbines, making it an indispensable asset for critical power generation and industrial applications. Its robust design, encapsulated in a sturdy sheet-metal chassis, ensures reliability even when faced with the rigors of industrial operations.

Key Features and Benefits

Versatile Speed and Load Control: The primary function of the WOODWARD 9907-2024 is to meticulously control the speed of prime movers and facilitate efficient load sharing. Whether you’re dealing with a standalone engine driving a pump or multiple generators synchronized to a grid, this module provides the precision needed to maintain optimal operating conditions. It’s particularly well-suited for complex setups involving engines isolated with torque converters and split shaft gas turbines, where dynamic control is paramount.

Selectable Control Modes (Isochronous & Droop): The 9907-2024 offers critical flexibility through its selectable control modes:

- Isochronous Mode: Ideal for single-prime-mover operations or when a constant speed is desired regardless of load changes. This mode ensures the prime mover maintains a precise speed, providing a stable frequency for generators.

- Droop Mode: Essential for parallel operation of multiple generators or prime movers. This mode allows for a controlled speed drop as load increases, facilitating stable load sharing among units without hunting or instability.

Robust and Field-Proven Design: As part of the 2301A series, the 9907-2024 is built for industrial longevity. Its compact design, featuring a single printed circuit board housed within a protective sheet-metal chassis, emphasizes durability. All adjustment potentiometers are conveniently accessible from the front, simplifying setup and maintenance.

Flexible Actuator Interface: The control module is designed to interface seamlessly with a proportional actuator. This actuator, in turn, precisely positions the fuel-metering device (like a fuel rack or valve), directly translating the electronic control signals into accurate mechanical adjustments to regulate the prime mover’s output.

Advanced Control Capabilities: Beyond basic speed and load control, the 9907-2024 includes advanced features to optimize prime mover performance:

- 4-20 mA or 1-5 Vdc Remote Speed Setting: Allows the prime mover’s speed or load to be set remotely via a process control signal or a computer, offering seamless integration into larger plant control systems.

- High and Low Speed Adjustments: Enables fine-tuning of operating limits to match specific application requirements.

- Start Fuel Limit with Override: Provides precise control over fuel delivery during startup, enhancing safety and preventing over-fueling, with an override option for specific operational needs.

Environmental Considerations: For optimal performance and longevity, it’s crucial to install the 9907-2024 in an environment free from excessive vibrations, moisture, high voltage interference, and electromagnetic interference (EMI). Its design is suited for closed industrial control cabinets.

Technical Specifications (Typical)

Application Areas

The WOODWARD 9907-2024 is a versatile control solution essential for a wide range of industrial applications requiring precise prime mover management:

- Generator Sets: For single-unit operation in isochronous mode or parallel operation with load sharing, ensuring stable frequency and power output.

- Industrial Turbines (Gas & Steam): Especially effective for split shaft gas turbines and other mechanical drive applications (e.g., driving compressors, pumps, fans/blowers) where accurate speed and load control are vital.

- Diesel/Gas Engines: Providing reliable governing for engines in various industrial settings.

- Marine Propulsion: For engines in marine applications requiring robust speed and load control.

- Power Plants: As a reliable component in the control system for turbogenerators.

Related Products

The WOODWARD 9907-2024 integrates with various other Woodward products and related systems:

- Woodward Actuators: The 9907-2024 requires a compatible proportional actuator to translate its electrical signals into mechanical movement of the fuel-metering device. Examples include ProAct actuators or other proportional hydraulic/electric actuators.

- Speed Sensing Devices (MPUs): Magnetic Pick-Up (MPU) sensors provide the speed feedback required by the controller.

- Load Sensing Devices: Optional devices like current and potential transformers (CTs/PTs) are used to measure generator load for load-sharing applications.

- Woodward SPM-A Synchronizer: Often used in conjunction with the 2301A series for precise synchronization of generators to a grid or other generators.

- Woodward GAP (Graphical Application Program): While the 2301A series may have limited direct GAP programming compared to newer controllers, GAP is used for other Woodward controllers within an integrated system.

- Distributed Control Systems (DCS) / PLCs: The 9907-2024 can communicate with higher-level DCS or PLC systems via its 4-20 mA or 1-5 Vdc inputs/outputs, allowing for remote monitoring and setpoint control.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922