الوصف

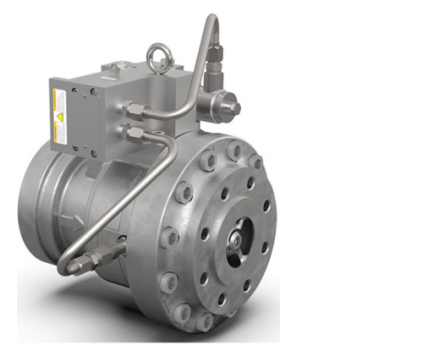

The WOODWARD 9907-2335 is a specific configuration of a GSOV80 Gas Fuel Shutoff Valve. This valve is a critical safety component designed for industrial gas turbines, used to rapidly and reliably stop the flow of gaseous fuel to the turbine.

WOODWARD 9907-2335: GSOV80 Gas Fuel Shutoff Valve

The WOODWARD 9907-2335 is an essential part of a turbine’s fuel system, providing a fast and secure means to shut off gaseous fuel flow in emergency situations or during normal shutdown sequences. Its robust design ensures high reliability in demanding industrial environments.

Product Overview

This particular part number represents a specific variant within Woodward’s GSOV80 series of gas fuel shutoff valves. These valves are built for high-pressure, high-flow applications typical of larger industrial gas turbines.

- Product Type: Gas Fuel Shutoff Valve

- Manufacturer: Woodward

- Part Number: 9907-2335

- Model Designation: GSOV80

- Key Specifications (based on Woodward’s product catalog and typical GSOV80 configurations):

- Port Size: 3.0 inches (80 mm), indicating it’s for large flow applications.

- Flange Type: High Pressure (HP) flanges, typically ANSI 600# RF Flanges (Raised Face 600 Class per ASME B16.5), which are standard for robust industrial piping connections.

- Body Material: Primarily stainless-steel construction, providing excellent corrosion resistance and durability, suitable for various gas fuels, including those in H2S-containing environments (NACE compliant per NACE MR0175/ISO 15156).

- Input Voltage: 125 VDC nominal (90 to 140 VDC).

- Electrical Connections: Features a circular connector for robust and reliable electrical wiring.

- Temperature Rating: Designed for low temperature operation.

- Closing Time: Extremely fast, less than 0.100 seconds after electrical supply current is interrupted.

- Opening Time: Less than 1 second.

- Valve Leakage Rating: Meets ANSI/FCI 70-2-2013 Class VI, indicating very tight shutoff.

- Documentation References: Product Specification: 03457, Manuals: 35189.

- Function: The GSOV80 valve acts as a positive shutoff device. When commanded by the turbine’s control system (e.g., in response to a safety trip or normal shutdown signal), it quickly de-energizes its solenoid, causing the valve to close rapidly and completely block the flow of gaseous fuel to the turbine. This rapid closure is vital for safe shutdown, preventing overspeed, or addressing other critical abnormal operating conditions.

Detailed Product Description

The Woodward 9907-2335 GSOV80 Gas Fuel Shutoff Valve is engineered for safety and reliability in demanding gas turbine applications. Key features common to the GSOV80 series that apply to this model include:

- Positive, Class VI Shutoff: Provides an exceptionally tight, leak-free seal when closed, adhering to ANSI/FCI 70-2-2013 Class VI, ensuring complete isolation of the fuel supply to the turbine. This is paramount for operational safety.

- Extremely Fast Acting: Engineered for rapid closure (less than 100 milliseconds) to quickly stop fuel flow during emergency shutdowns, minimizing potential damage or hazardous conditions.

- High Pressure Capability: Built to withstand and operate reliably under the high pressures (up to 9.93 MPa / 1440 psig operating pressure; 15 MPa / 2175 psig proof pressure) associated with gaseous fuel delivery in large industrial turbines.

- Robust Stainless Steel Construction: The all-stainless steel construction offers superior corrosion resistance and durability, making it suitable for a wide range of gaseous fuels, including those containing H2S (sour gas).

- Integrated Filtration: An integral 40 µm (nominal) filter screen protects critical internal components from particulate contamination, enhancing reliability and extending service life.

- Electrical Actuation: Operates via electrical power (125 VDC) to its solenoid interface from the control system, allowing for precise and integrated control within the overall turbine management system. The circular connector provides a secure and reliable electrical interface.

- Low Temperature Operation: This specific configuration is designated for “Low Temp” operation, meaning it’s designed to perform reliably in colder ambient conditions, broadening its applicability across diverse geographical climates.

- Minimal Pressure Drop: The valve’s design often prioritizes a straight-through flow path to minimize pressure drop, which contributes to lower gas compression operating costs. Critical moving parts and seals are kept out of the main flow stream to reduce wear.

Technical Specifications (for the 9907-2335 GSOV80)

Typical Applications

The WOODWARD 9907-2335 GSOV80 Gas Fuel Shutoff Valve is commonly found in safety-critical roles within:

- Large Gas Turbine Power Generation: Used in power plants to ensure the rapid and safe shutdown of gas turbines.

- Oil & Gas Industry: Employed in gas turbines driving compressors or pumps in pipelines, processing facilities, and offshore platforms, where emergency fuel cutoff is vital, particularly in environments with H2S or other contaminants.

- Industrial Cogeneration Plants: Part of the safety system for gas turbines used in combined heat and power applications.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922