الوصف

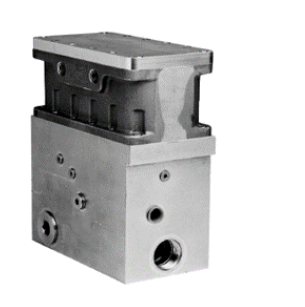

The WOODWARD 9908-358 is a specific configuration of a GS6 Gas Fuel Metering Valve. This valve is a crucial component designed for precise and reliable control of gaseous fuel flow, primarily in aeroderivative gas turbines.

WOODWARD 9908-358: GS6 Gas Fuel Metering Valve

The WOODWARD 9908-358 plays a vital role in a turbine’s fuel system. It’s engineered to accurately meter and control the flow of gaseous fuel into the combustion chamber, which is essential for efficient, stable, and environmentally compliant turbine operation.

Product Overview

This particular part number represents a specific variant within Woodward’s GS6 series of gas fuel metering valves. The GS6 valves are known for their compact size, fast response, and accuracy, making them ideal for aeroderivative gas turbines and other applications requiring dynamic fuel control.

- Product Type: Gas Fuel Metering Valve

- Manufacturer: Woodward

- Part Number: 9908-358

- Model Designation: GS6

- Key Specifications (based on Woodward’s product catalog and typical GS6 configurations for this P/N):

- Port Size / Active Area (ACD): The GS6 series offers various metering port areas (0.15 in², 0.30 in², 0.45 in², 0.60 in², and 0.75 in²). The

9908-358specific configuration often corresponds to a particular active area, optimizing it for specific turbine flow requirements. - Flange Type: Typically uses 1.5-inch (38 mm) SAE Code 61 Flanges for its inlet and discharge connections, a common standard for fluid connections in industrial applications.

- Input Voltage: 24 VDC (ranging from 18 to 32 VDC).

- Electrical Connections: This specific part number uses conduit entry driver connections for electrical wiring, with terminal blocks in an integral junction box.

- Features: Includes dual resolvers for redundant position feedback, enhancing reliability in critical applications. It also features dual signal conditioning, resolver fault detection, and selectable failure management options.

- Port Size / Active Area (ACD): The GS6 series offers various metering port areas (0.15 in², 0.30 in², 0.45 in², 0.60 in², and 0.75 in²). The

- Function: As an electrically actuated fuel valve with an on-board electronic positioner controller, it precisely controls the flow of gaseous fuel based on command signals from the turbine’s electronic control system. This ensures optimal fuel delivery for all phases of turbine operation, including start-up, acceleration, load changes, and steady-state running. The high accuracy and dynamic response are crucial for maintaining turbine performance and achieving low emissions (e.g., in Dry Low Emission – DLE – combustion systems).

Detailed Product Description

The Woodward 9908-358 GS6 Gas Fuel Metering Valve is engineered for high performance and exceptional reliability in demanding gas turbine applications. Key features common to the GS series, and thus found in this specific model, include:

- Integrated Electronic Position Controller with On-Board Driver: The valve incorporates an integrated electronic controller module and driver. This enables precise and rapid positioning of the internal metering element in response to control signals, ensuring accurate fuel delivery and dynamic response. This integration simplifies system packaging and installation by eliminating the need for an external driver cabinet.

- Self-Cleaning, Shear-Type Metering Action: A hallmark of the GS series, this unique design actively cleans the metering port. This prevents performance degradation caused by deposits of gas condensates, contaminants, and system debris, which is crucial for extending operational periods between overhauls, especially with varied or less-than-ideal fuel gas quality.

- Single Moving Part Design: The valve’s design typically features a single moving part where the fuel-metering element, actuator rotor, and position feedback resolvers are mounted on a single solid-piece shaft. This minimizes wear parts, greatly enhancing reliability and longevity by eliminating backlash and providing virtually infinite valve positioning resolution.

- High Accuracy and Repeatability: By using a spherical fuel metering element with a precision-machined port and high-precision resolvers for position feedback, the valve achieves highly accurate and repeatable fuel flow control. This is vital for maintaining turbine speed, power output, and emissions compliance.

- Dual Resolver Feedback: The presence of dual resolvers (as indicated by the part number’s typical configuration) provides redundant position feedback, significantly increasing the reliability and fault tolerance of the valve, making it suitable for critical applications where uninterrupted operation is paramount.

- Robust Shut-off Capability: The valve typically provides a positive flow shut-off that meets or exceeds industry standards.

- Wide Flow Range: Despite its compact size, the GS6 can handle a wide range of gas flow rates, making it versatile for various turbine sizes within its operational range.

Technical Specifications (for the 9908-358 GS6)

Typical Applications

The WOODWARD 9908-358 GS6 Gas Fuel Metering Valve is commonly found in a variety of high-performance industrial applications where precise gas fuel control is critical:

- Aeroderivative Gas Turbines: Its primary application is in aeroderivative gas turbines for power generation, mechanical drive, or marine propulsion, where its fast response, compact design, and reliability are highly beneficial.

- Small to Medium-Sized Industrial Gas Turbines: Used in other industrial gas turbine applications that fall within its flow and pressure ratings.

- Applications with Varied Fuel Gas Quality: The self-cleaning design makes it suitable for wellhead gas applications or where the fuel gas may contain contaminants.

- Critical Applications: The dual resolver feedback makes this a preferred choice for applications demanding high reliability and fault tolerance.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922