الوصف

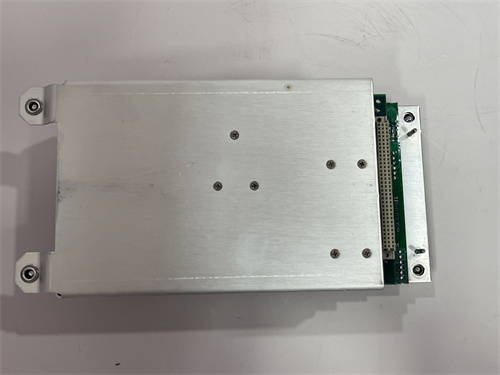

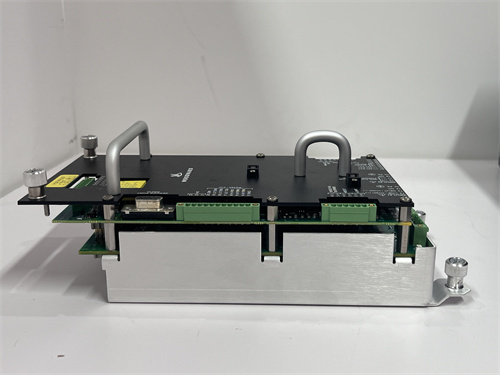

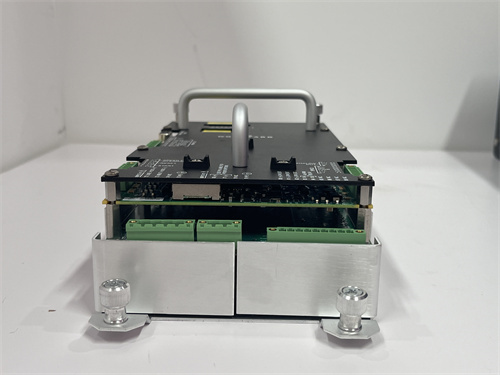

WOODWARD 5437-523 Product Overview

Product Name

WOODWARD 5437-523 Digital Control

Product Description

The WOODWARD 5437-523 is a sophisticated digital control designed for industrial applications demanding precise and reliable operation. This advanced control unit is engineered to optimize the performance of machinery and equipment across diverse sectors. The WOODWARD 5437-523 control offers superior performance and accuracy, making it a valuable asset for your industrial setup. With its advanced capabilities and robust design, the WOODWARD 5437-523 ensures seamless integration and enhanced operational efficiency. Investing in the WOODWARD 5437-523 means investing in the longevity and productivity of your automated systems. The reliability of the WOODWARD 5437-523 is a testament to WOODWARD’s commitment to quality.

Product Parameters

- Input Voltage: 24 VDC

- Operating Temperature: -40°C to +70°C

- Communication Protocols: Modbus RTU, Ethernet

- Number of I/O: 16 Digital Inputs, 8 Digital Outputs, 4 Analog Inputs, 2 Analog Outputs

- Processor Speed: 400 MHz

- Memory: 128 MB Flash, 64 MB RAM

- Dimensions: 200mm x 150mm x 100mm

- Weight: 1.5 kg

Advantages and Features

- High Precision Control: Ensures accurate and reliable operation.

- Robust Design: Resistant to harsh industrial environments.

- Flexible Communication: Supports multiple communication protocols for seamless integration.

- Expandable I/O: Allows for easy expansion and customization.

- User-Friendly Interface: Simplifies programming and maintenance.

- Real-time Monitoring: Provides immediate feedback on system performance.

- Fault Diagnostics: Quickly identifies and resolves issues, minimizing downtime.

Application Areas and Application Cases

- Power Generation: Used in gas turbines, steam turbines, and generators for precise control and monitoring.

- Application Case: In a power plant, the WOODWARD 5437-523 optimizes turbine efficiency by controlling fuel flow and air intake, resulting in significant energy savings.

- Oil and Gas: Used in compressors, pumps, and pipelines for accurate control and monitoring of critical processes.

- Application Case: On an offshore platform, the WOODWARD 5437-523 manages the compression process, ensuring stable and safe operation.

- Manufacturing: Used in assembly lines, robotic systems, and automated machinery for precise control and coordination.

- Application Case: In an automotive factory, the WOODWARD 5437-523 controls robotic arms for precise welding and assembly tasks, improving production quality and speed.

- Water Treatment: Used in pumps, valves, and filtration systems for accurate control and monitoring of water treatment processes.

- Application Case: In a water treatment plant, the WOODWARD 5437-523 regulates the flow of chemicals and monitors water quality, ensuring compliance with environmental standards.

- Aerospace: Used in aircraft engine controls, hydraulic systems, and flight control surfaces for precise control and reliable performance.

Competitive Product Comparison

| Feature | WOODWARD 5437-523 | Competitor A (e.g., Siemens S7-1200) | Competitor B (e.g., Allen-Bradley CompactLogix) |

|---|---|---|---|

| Precision Control | High | Medium | High |

| Operating Temp | -40°C to +70°C | -20°C to +60°C | -25°C to +70°C |

| Communication | Modbus RTU, Ethernet | Profinet, Modbus TCP | EtherNet/IP, Modbus TCP |

| I/O Flexibility | Expandable | Limited Expansion | Expandable |

| User Interface | User-Friendly | Intermediate | Advanced |

| Real-time Monitoring | Yes | Yes | Yes |

| Fault Diagnostics | Advanced | Basic | Intermediate |

| Applications | Power Generation, Oil & Gas, Manufacturing, Water Treatment | General Automation, Small to Medium Applications | Advanced Automation, Large Applications |

| Price | Competitive | Moderate | High |

Selection Advice

- Application Requirements: Consider the specific control requirements of your application, such as precision, speed, and environmental conditions.

- Communication Needs: Ensure the WOODWARD 5437-523 supports the communication protocols used in your system.

- I/O Capacity: Determine the number of inputs and outputs required for your application and choose a model with sufficient capacity.

- Environmental Conditions: Select a model that can withstand the environmental conditions of your application, such as temperature, humidity, and vibration.

- Future Expansion: Choose a model that can be easily expanded to accommodate future growth and changes in your application.

Important Considerations

- Proper Installation: Ensure the WOODWARD 5437-523 is installed correctly to prevent damage and ensure reliable operation.

- Regular Maintenance: Perform regular maintenance, such as cleaning and inspection, to prolong the life of the control.

- Software Updates: Keep the control software up to date to ensure optimal performance and security.

- Environmental Protection: Protect the control from harsh environmental conditions, such as excessive heat, moisture, and vibration.

- Power Supply: Use a stable and reliable power supply to prevent damage to the control.

- Safety Precautions: Follow all safety precautions when working with the control to prevent injury and equipment damage.

We are your reliable partner, offering the WOODWARD 5437-523 and other automation spare parts sales and technical support. Get special discount prices. Please contact us, we will serve you wholeheartedly!

WOODWARD+5437-523

| IS200TTURH1B PLC |

| IC695CPE310 PLC |

| IS200TSVOH1B PLC |

| IC695CPU315-BB DCS |

| IS200VVIBH1C PLC |

| IS200TDBTH6A PLC |

| IS200TBAIH1C |

| Fanuc UCVD.H2AIS215UCVDH2AM PLC |

| IC697CPX782-CD |

| IS200STURH2A PLC |

| IS200TBTCH1B PLC |

| IS200VPROH1B PLC |

| IS220PPDAH1A PLC |

| Fanuc IC693CPU331K PLC |

| IS200TDBSH2A PLC |

| IS220SRTDH2A PLCCPU |

| IS200ECTBG2A PLC |

| IS420UCSBH1A |

| IS200VCRCH1B PLC |

| IS220PDIOH1A PLC |

| IS220PPDAH1B PLC |

| IS220PAICH1B PLC |

| HE700GEN200 PLC |

| HE700GEN200C PLC |

| 8ETM001 |

| 8CPE030 |

| 8PSA100 |

| 8CHS009 |

| FANUC IS230STAI2ASRTD2AH01 |

| IS220PAICH1 |

| HEE300744R1 UAC318AE |

| HIEE300766R1 |

| GDB021BE |

| HIEE30077 |

| 71R1HAC319AEV1 |

| HEE300771R1 UNS0874A |

| H00900R000 PPC322BE |

| HIEE300910R1 |

| UFC092BE01 |

| HIEE320639R1 LT8978DV1 |

| HEE400103R1 CSA463AE |

| HIEE400106R1 CSA464AE PLC |

| HIEE40109 CPU |

| 1R00O2 GD9924BE |

| HEE401481R0001 UAC326AE PLC |

| HEE450964R0001 SA99238A-E PLC |

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922