الوصف

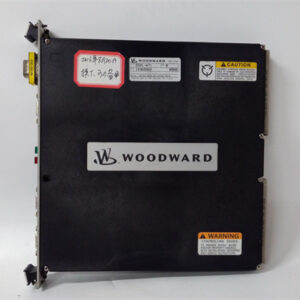

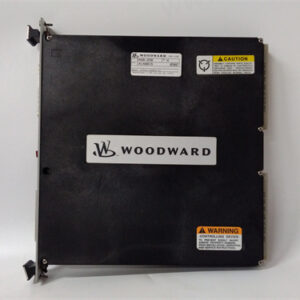

Woodward+8440-2052 H PLC Module

Product Name:

Woodward+8440-2052 H – PLC Module

Product Description:

The Woodward+8440-2052 H is a highly capable Programmable Logic Controller (PLC) designed for use in industrial applications requiring high reliability, precision control, and real-time monitoring. As part of Woodward’s extensive range of control and automation solutions, this module is specifically engineered to handle complex control tasks, optimize processes, and provide seamless integration with a variety of industrial systems.

Woodward has long been known for its expertise in power generation, industrial control, and automated systems, and the +8440-2052 H PLC Module is no exception. It offers robust processing power, flexibility for system expansion, and a range of advanced features designed for high-performance automation in industries like energy, marine, power generation, and process control. The module is designed to provide high levels of control and monitoring capabilities in mission-critical applications, ensuring maximum efficiency and uptime.

With a modular design, this PLC can be easily integrated into existing control systems, offering flexibility for expansion and customization to meet the unique needs of industrial operations. Additionally, the +8440-2052 H module is engineered to withstand the rigors of industrial environments, including wide temperature ranges, electromagnetic interference (EMI), and vibration.

Key Features:

-

Real-Time Control & Monitoring:

- Provides real-time monitoring and control capabilities, which are crucial for mission-critical industrial processes.

-

Modular Architecture:

- The PLC’s modular design allows for easy customization and scalability, enabling users to expand their control systems as needed.

-

Multiple Communication Protocols:

- Supports Ethernet, Modbus, CAN, and RS-232/RS-485 communication protocols, ensuring easy integration with other devices and automation systems.

-

Advanced Diagnostic Tools:

- Includes built-in self-diagnosis features for proactive fault detection and troubleshooting, minimizing downtime and enhancing system reliability.

-

Flexible I/O Configuration:

- Supports both digital and analog I/O to cater to a wide variety of industrial control applications, from simple ON/OFF devices to complex sensor and actuator control.

-

High-Performance Processing:

- The +8440-2052 H offers excellent processing capabilities, making it ideal for demanding applications requiring high-speed data handling and control.

-

Industrial Durability:

- Designed to withstand challenging conditions such as extreme temperatures, humidity, and vibrations, ensuring reliable operation in harsh industrial environments.

Product Parameters & Specifications:

General Information:

-

Model:

- Woodward+8440-2052 H PLC Module

-

Brand:

- Woodward

-

Part Number:

- 8440-2052 H

-

Category:

- Programmable Logic Controller (PLC)

-

Application:

- Industrial Automation, Power Generation, Energy Systems, Marine Applications, Process Control, Automation Systems

Power Supply:

-

Nominal Voltage:

- 24V DC, typical for industrial PLC modules.

-

Input Voltage Range:

- Typically 20V to 30V DC.

-

Power Consumption:

- Varies by configuration but typically between 20W to 40W depending on I/O modules and load.

Operating Conditions:

-

Operating Temperature Range:

- -20°C to +60°C (-4°F to 140°F), designed to operate reliably in diverse environmental conditions.

-

Storage Temperature Range:

- -40°C to +85°C (-40°F to 185°F), ensuring safe operation when stored in extreme conditions.

-

Relative Humidity:

- 5% to 95%, non-condensing.

-

Protection Rating:

- Typically IP20 or IP65 (when used within enclosures), providing protection against dust and splashes of water.

-

Vibration Resistance:

- Meets industrial vibration standards for enhanced durability.

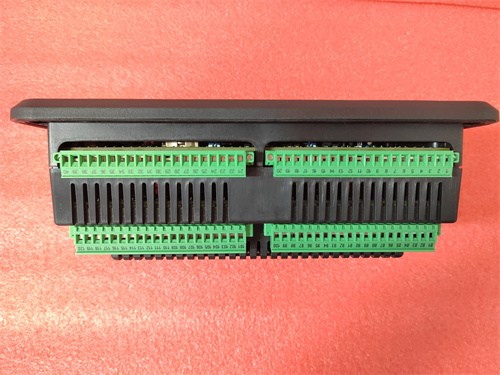

I/O Specifications:

-

Digital I/O:

- Supports digital inputs and outputs for controlling simple on/off devices like relays, switches, and solenoids.

-

Analog I/O:

- Includes analog inputs (e.g., temperature, pressure sensors) and analog outputs (e.g., actuators, motor control).

-

I/O Expansion:

- The system is scalable with additional expansion modules to support more digital and analog I/O points, allowing flexibility for larger and more complex automation systems.

-

Communication Ports:

- Ethernet, Modbus, CAN, RS-232/RS-485 for communication with other controllers, sensors, and devices.

Performance & Control Features:

-

Processing Speed:

- Offers high-speed control and data processing capabilities to meet the demands of time-sensitive industrial applications.

-

Control Algorithms:

- Supports PID control, SFC (Sequential Function Chart), and other standard control algorithms for a wide range of automation tasks.

-

Redundancy Features:

- Available with redundant configurations for critical control systems, ensuring high availability and fault tolerance.

-

Advanced Diagnostics:

- Equipped with real-time diagnostic tools for detecting system faults, providing detailed status reports, and helping with troubleshooting and system maintenance.

Compliance & Certifications:

-

Safety Standards:

- Compliant with international standards such as UL, CE, and CSA, ensuring the product can be used globally with safety in mind.

-

Electromagnetic Compatibility (EMC):

- Meets EMC standards to prevent interference from external sources and to protect against electrical noise in industrial settings.

Applications:

-

Industrial Automation:

- Widely used in manufacturing plants, production lines, and factory automation to control and monitor automated processes.

-

Power Generation:

- Suitable for power plants, substations, and energy systems, where real-time control and reliable operation are crucial.

-

Marine Applications:

- Used in marine vessels, including engine control, fuel systems, and electrical power systems.

-

Process Control:

- Ideal for industries requiring precise control such as chemical, food processing, and oil and gas.

-

Energy Systems:

- Common in renewable energy, smart grids, and HVAC systems where efficient energy management and real-time control are required.

Summary of Key Features:

- Real-time control and advanced diagnostics for mission-critical applications.

- Modular and scalable design, ideal for growing or changing industrial systems.

- High-performance processing for fast, reliable control.

- Multiple communication protocols for seamless integration with other systems and devices.

- Industrial-grade durability to withstand harsh operating conditions.

- Advanced I/O expansion options for scalable and flexible control configurations.

If you need further details about the Woodward+8440-2052 H PLC Module, or have specific questions about its application, feel free to ask!

ABB RDCO-02C PLC

ABB SDCS-UCM-1C PLC

SDCS-CON-2B ABB PLC

ABB 3BSE018106R1 PLC

ABB IMCPMO2 PLC

IMCPMO2 ABB

ABB 3BSE012545R1 PLC

ABB CI546 PLC

ABB CI546 3BSE012545R1 PLC

3BHL000385P0101B PLC

ABB 5SHX0845F0001 DCS

ABB 3BHL000386P0101

ABB 5SHX0660F0001 PLC

ABB 5SHX0360D0001 PLC

DSAI130 DCS

ABB DSAI130 PLC

HL000384P0101 PLC ABB

ABB TC512V1 DCS

TC512V1 ABB

PU515 ABB PLC

ABB PU515 PLC

ABB APOW-01C PLC

3BSE008514R1 ABB PLC

ABB 3BSE013230R1 PLC

ABB 900R08-0101 PLC

ABB DSAI 133

DSAI 133 ABB I/O

ABB DSTA 156B PLC

ABB DSTA 156B

ABB DSTA 001B PLC

DSTA 001B ABB DCS

ABB DSTD 150A PLC

DSAI 133A PLC

ABB DSTD 150A PLC

ABB DSAI 133A PLC

ABB GRBTU-01 DCS

3BSE013175R1 ABB DCS

ABB A0810V2 PLC

ABB CI854AK01 PLC

NDCU-51 ABB PLC

AB 1764-LSP DCS

ABB NIOC-01 PLC

NAMC-51C ABB PLC

ABB 3BSE018161RI PLC

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922