الوصف

Product Name:

Product Name:

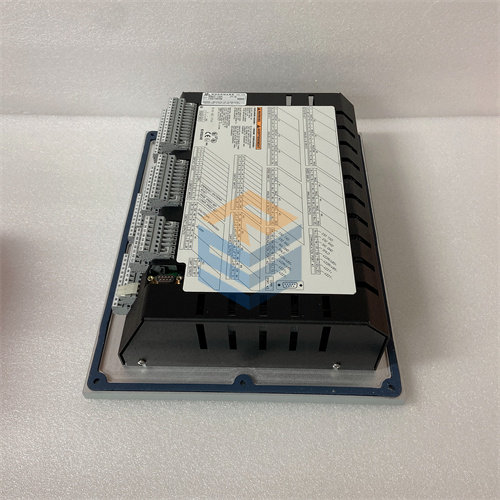

WOODWARD 9907-167 DCS PLC Module

Product Description:

The WOODWARD 9907-167 is a high-performance Distributed Control System (DCS) PLC module designed for use in industrial process control applications, including power generation, oil and gas, and other critical infrastructure industries. The 9907-167 module is part of the Woodward Integrated Control Systems, which are known for their precision, reliability, and flexibility.

This module is built to provide robust control and monitoring of complex industrial processes, offering scalability and integration with other control and monitoring systems. It supports advanced features like redundancy for critical operations, real-time processing, and the ability to interface with various field devices using a wide range of industrial communication protocols. The 9907-167 ensures highly reliable control in challenging environments, making it suitable for industries where operational continuity and safety are of paramount importance.

Product Parameters:

- Module Type: DCS/PLC Control Module (For Distributed Process Control and Automation).

- System Compatibility: Compatible with Woodward’s integrated control systems for industries like power generation, oil and gas, and water treatment.

- Communication Protocols: Supports multiple protocols, including Modbus, Profibus, Ethernet/IP, and CANbus, allowing seamless integration with a variety of field devices and control systems.

- I/O Capacity: Offers flexible digital and analog I/O configurations to suit a wide range of applications.

- Redundancy Support: Provides redundant communication channels and power supplies for high availability in mission-critical applications.

- Enclosure Protection: The module is designed to meet high standards for IP ratings to ensure resistance to dust, moisture, and other environmental factors in industrial settings.

- Power Supply: Typically requires 24V DC input power.

Product Specifications:

1. Processor and Performance:

- Processor Type:

- The 9907-167 module is powered by a high-performance microprocessor optimized for real-time processing and control of industrial processes. It offers fast computation and low-latency performance for time-sensitive control loops.

- Performance:

- The module supports high-speed control loops with the ability to manage large volumes of data and execute complex control algorithms with minimal delay. Its real-time performance ensures that industrial operations are continuously optimized.

2. Memory:

-

RAM:

- The module comes equipped with sufficient memory to handle real-time data storage and temporary operations. The RAM capacity typically ranges from 4 MB to 16 MB depending on the configuration.

-

Non-Volatile Storage:

- The module includes flash memory or EEPROM to store configuration settings, control logic, and other important parameters, ensuring that the data persists even after power cycles.

3. I/O and Expansion:

- I/O Channels:

- The 9907-167 module provides extensive I/O options for connecting to a variety of sensors, actuators, and control devices. It can accommodate both digital and analog I/O for monitoring and controlling processes.

- Modular Expansion:

- The module allows for flexible expansion with additional I/O modules, communication interfaces, and redundant power configurations to meet the needs of larger, more complex systems.

4. Communication and Networking:

- Ethernet/IP and Fieldbus Integration:

- The 9907-167 supports a variety of communication protocols like Ethernet/IP, Modbus, and Profibus, enabling seamless integration with other control systems, SCADA systems, and remote devices.

- Redundancy:

- Built-in redundant communication channels (e.g., dual Ethernet or Fieldbus) help ensure continuous system operation, even in the event of network failure.

5. Power Requirements:

-

Operating Voltage:

- The module typically operates with a 24V DC input power, although different configurations may allow for 48V DC systems, depending on the installation requirements.

-

Power Consumption:

- Power consumption varies based on connected devices and the configuration, with the module generally consuming between 30W and 50W under typical operating conditions.

6. Environmental Specifications:

-

Operating Temperature Range:

- The 9907-167 is rated to operate in temperatures from -20°C to +60°C, ensuring functionality in a variety of industrial environments.

-

Humidity Range:

- The module can function within a 5% to 95% non-condensing humidity range.

-

Shock and Vibration Resistance:

- It is designed to withstand industrial shock and vibration, compliant with standards like IEC 60068 for reliability in challenging industrial environments.

-

Protection Rating:

- The module is typically rated IP20 or IP65, depending on the specific configuration, offering protection from dust and moisture.

7. Physical and Mechanical Specifications:

-

Form Factor:

- The module is usually DIN Rail mountable for easy installation in control cabinets or control panels.

-

Dimensions:

- Approximate size of the module is 160 mm x 120 mm x 50 mm (HxWxD), though it can vary based on additional features or modules.

-

Weight:

- The typical weight of the WOODWARD 9907-167 module is around 1.2 kg to 1.8 kg, depending on the configuration and connected components.

Key Features and Benefits:

-

Real-Time Performance:

- Designed to handle complex process control in real-time, making it ideal for time-sensitive applications.

-

Scalable and Modular:

- Offers flexible scalability through expansion modules, supporting a range of I/O types and additional control components.

-

High Availability:

- Redundant features for both communication and power supply, ensuring that mission-critical systems remain operational with minimal downtime.

-

Environmental Durability:

- Withstanding harsh conditions like high temperatures, moisture, and mechanical shock, the module is engineered for industrial environments.

-

Seamless Communication:

- The wide range of supported communication protocols (e.g., Ethernet/IP, Modbus, Profibus) ensures compatibility with various field devices and control systems.

Applications:

- Power Generation: Used in power plants for turbine control, generator management, and auxiliary equipment.

- Oil and Gas: Ideal for refineries, offshore platforms, and pipelines, where precise control and monitoring are needed.

- Water and Wastewater Treatment: Automation of filtration, pumping, and dosing systems in water treatment plants.

- Chemical and Petrochemical: Control of reactors, distillation columns, and mixing processes in chemical production.

- Industrial Automation: Ideal for manufacturing and process automation industries requiring reliable and scalable control systems.

Conclusion:

The WOODWARD 9907-167 DCS PLC Module is a versatile, reliable, and high-performance control solution for demanding industrial environments. With its ability to manage complex systems, support real-time data processing, and ensure high availability through redundancy features, it is ideal for industries where operational continuity and safety are critical. Whether in power generation, oil and gas, or water treatment, this module offers the flexibility, scalability, and performance required to optimize industrial processes.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922