الوصف

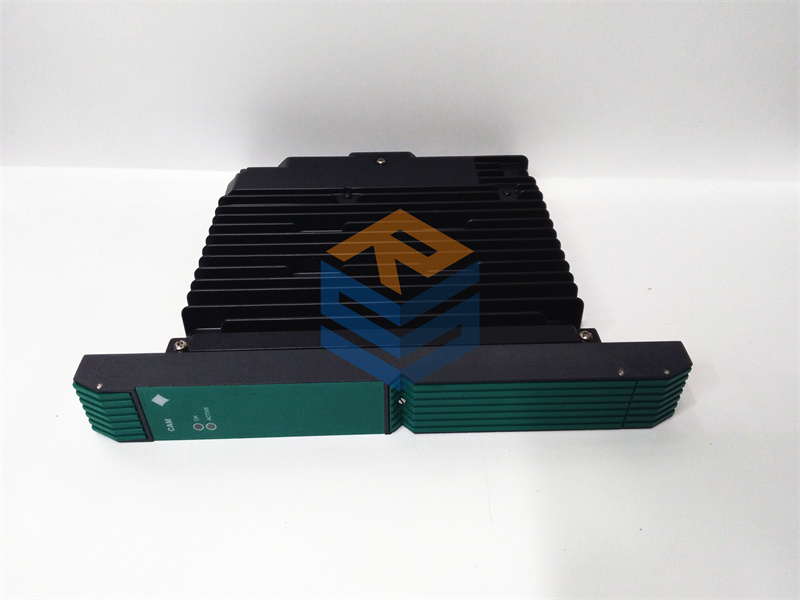

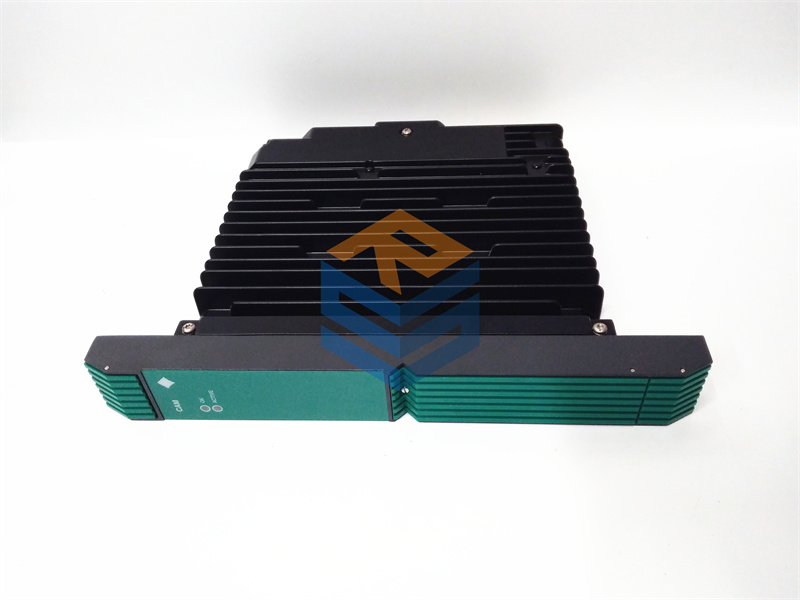

Sure! Here is an overview of the Yokogawa PSCAMAA DCS PLC Module, based on available information:

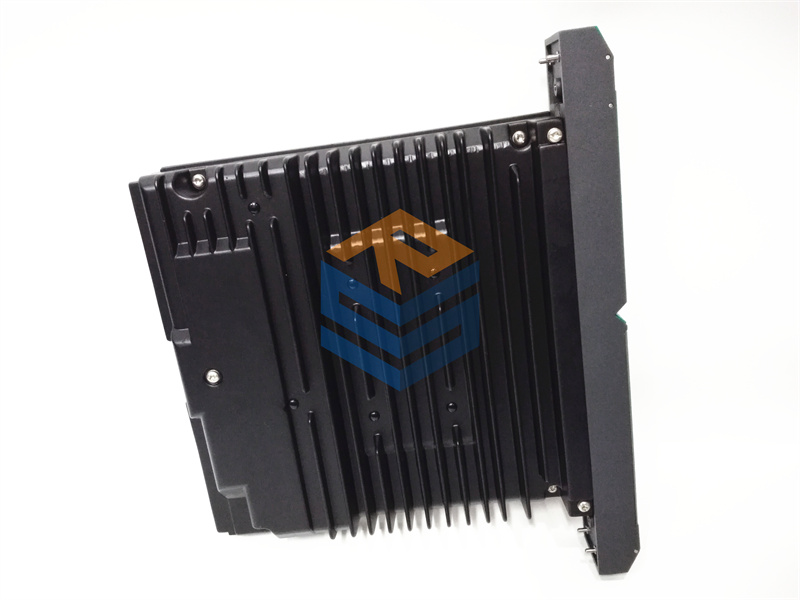

Yokogawa PSCAMAA DCS PLC Module

Product Name:

Yokogawa PSCAMAA DCS PLC Module (Yokogawa PSCAMAA Control Module)

Product Description:

The Yokogawa PSCAMAA is part of the Centum VP family of Distributed Control Systems (DCS) designed for high-precision process control and automation in industrial applications. It is a versatile, high-performance module that provides enhanced control and monitoring features for mission-critical processes. With its open architecture and flexible integration capabilities, the PSCAMAA module is ideal for industries that require reliability, scalability, and efficient performance, such as petrochemicals, power generation, oil & gas, and manufacturing.

The PSCAMAA DCS PLC Module is designed to support both analog and digital control functions, and it integrates seamlessly with other Yokogawa equipment, making it a key component for modern industrial automation systems. It provides sophisticated control algorithms, advanced diagnostic features, and redundancy options to ensure the continuous operation of critical processes.

Product Parameters and Specifications:

- Model: Yokogawa PSCAMAA

- Type: DCS PLC Module (for Centum VP system)

- Control: Suitable for both process control and discrete control applications

- Input Voltage: Typically 24 VDC, though specific models may vary based on requirements

- Power Consumption: Low power consumption, optimized for energy efficiency

- Operating Temperature:

- Typically, between -20°C and +60°C, but check specific conditions based on the model and environment

- Dimensions:

- Typically around 150 mm x 100 mm x 50 mm (exact dimensions depend on model version)

- I/O Capacity:

- Digital I/O: Up to 16 inputs/outputs (expandable)

- Analog I/O: Up to 8 inputs/outputs (expandable with additional modules)

- CPU: High-performance processor with optimized real-time control algorithms

- Communication Protocols:

- Modbus, Profibus DP, OPC, Ethernet/IP, and Yokogawa proprietary protocols (e.g., Exaopc, ExaEdge)

- Support for Yokogawa’s Fieldbus communication standards

- Fieldbus Integration: Supports Yokogawa FIO and FCS (Field Control Station) devices

- Data Processing Speed: High-speed, low-latency control and data processing for real-time decision-making

- Redundancy: Redundant configurations are available (for critical applications, such as dual CPUs and power supplies)

- Environmental Protection: Typically meets IP20/IP30 or higher (depending on model)

- Diagnostic Features: Integrated diagnostic capabilities for health monitoring, error detection, and system maintenance

- Mounting Type: Rack-mounted or modular integration within the Yokogawa Centum VP architecture

- Safety Certifications: UL, CE, and other region-specific certifications may apply (depending on the module)

Key Features and Advantages:

- Real-Time Control: Provides advanced control algorithms and fast data processing, allowing for precise real-time adjustments to processes.

- Modular Design: The PSCAMAA module can be expanded with additional modules to accommodate growing I/O requirements.

- Open Architecture: Seamless integration with a wide range of devices and systems, including third-party equipment, making it highly adaptable for different industrial applications.

- Advanced Diagnostics: Includes diagnostic features for troubleshooting and ensuring smooth operation, reducing downtime.

- High Reliability: Designed for industrial environments with robust features that ensure continued operation even under harsh conditions.

- Communication Flexibility: Support for multiple communication protocols enables easy integration into diverse automation systems.

- Redundancy for High Availability: Optional redundancy configurations (power supply, CPU, network) ensure high availability and uptime in critical systems.

- Centralized and Distributed Control: Flexible control options allow for both centralized and distributed automation strategies within a plant.

Application Areas:

The Yokogawa PSCAMAA DCS PLC Module is used across a wide range of industries and is particularly beneficial in:

- Petrochemical: Process control in oil refineries, petrochemical plants, and natural gas production facilities.

- Power Generation: Automation of power plants, including monitoring and controlling turbines, generators, and electrical distribution systems.

- Oil & Gas: Upstream (exploration and extraction) and downstream (refining) applications, including the control of pumps, valves, and pipelines.

- Chemical Industry: Precise regulation of chemical reactions, temperature, pressure, and other critical variables.

- Manufacturing: Control systems for automated production lines, packaging, assembly processes, and quality assurance.

- Water & Wastewater Treatment: Automation of water treatment processes, chemical dosing, filtration, and wastewater management.

- Building Automation: Integration into building control systems, including HVAC, lighting, and security systems in commercial and residential buildings.

Comparison with Competitors:

When comparing Yokogawa PSCAMAA with other DCS PLC modules from competitors (such as Siemens PCS 7, Honeywell Experion, and Schneider Electric Foxboro), the following advantages can be noted:

- Integration with Centum VP: The Yokogawa PSCAMAA seamlessly integrates into the Centum VP DCS platform, offering an ideal solution for plants already using Yokogawa systems.

- Reliability: Yokogawa’s systems are known for their high reliability in critical environments, ensuring continuous operation in even the most demanding industries.

- Advanced Diagnostic Tools: The PSCAMAA module offers robust diagnostic features that aid in early fault detection, reducing downtime and minimizing the risk of failure.

- Modularity and Scalability: The modular design of PSCAMAA makes it easy to scale the system as needed, which is a significant advantage in growing industries.

- Open Communication Standards: The PSCAMAA supports a variety of communication protocols, including Modbus, OPC, and Profibus, making it adaptable to a wide range of industrial setups.

Selection Considerations:

When selecting a Yokogawa PSCAMAA DCS PLC Module, consider the following factors:

- Application Requirements: Ensure that the module can handle the required number of I/O points, communication protocols, and processing speed for your specific application.

- Integration with Existing Systems: The PSCAMAA integrates seamlessly with other Yokogawa equipment, so consider the broader architecture of your control system.

- Redundancy and Reliability: If your application requires high availability, ensure that redundancy configurations (e.g., dual power supplies and CPUs) are selected.

- Environmental Conditions: Ensure that the module meets the environmental specifications required for your plant conditions (temperature, humidity, vibration, etc.).

- Long-Term Support: Consider the longevity of the system and Yokogawa’s support offerings for maintenance, troubleshooting, and system upgrades.

Conclusion:

The Yokogawa PSCAMAA DCS PLC Module is a robust, flexible, and high-performance control module designed for demanding industrial applications. With its real-time control capabilities, modular design, and diagnostic features, it is ideal for industries such as petrochemical, power generation, and manufacturing. When integrated with the Centum VP DCS, it provides a scalable and reliable automation solution that can handle both complex and simple control tasks efficiently.

D663Z4323K /PO3JONF6VSX2-A MOOG

D664-4707 L05HYBW5NSX4-O PLC

D664-4009/LO5HABF6VSX2-A

IS220PPRFH1B PLC

D664-Z4309NP05HXMM6NEX2-E PLC

IS220PCNOH1B PLC I/O

D664-4010 PLC

D664-372K/P05HAMWFNVB0 PLC

D665-4746 PLC

MX-CS101-701-G1 PLC

PR6423/003-030+CON021 PLC

PR6423/003-030-CN PLCI/O

CON021 PLC

CON021/916-160 PLC

PR6423 PLC

PR6423/003-030 PLC

PPD115A102 3BHE017628R0102

3BSE042238R2 PP846A

996920302 K9203 HIMA

996920261 K9202B PLC

996920202 K9202 PLC

BENTLY 3500/22M PLC

TRICONEX AO3481 3481 CPU

FANUC A05B-2452-C900 PLC

PR6423/010-010+CON021 DCS

PR6423/014-040 PLC

FANUC A05B-2452-C900 PLC

NI SCXI-1125 PLC

8521-EB-MT PLC

MOTOROLA MVME162-220

D665-4746

G761-3008 MOOG PLC

G761-3004 MOOG I/O

G761-3016BMOOG PLC

G761-3005MOOG PLC

G761-3001MOOG PLC

G761-3003 MOOG PLC

G761-3002MOOG PLC

G761-3025MOOG PLCI/O

G761-3025MOOG PLC

G761-3023BMOOG PLC

G761-3009MOOG PLC

G761-3605MOOG

G761-3600MOOG PLC

G761-3016MOOG PLC

G761-2760 S19KOFA5UALMOOG I/O

D761-2751A-5MOOG PLC

G631-3704AMOOG PLC

G631-3009BMOOG PLC

G631-3005BMOOG PLC

G631-3006B MOOG PLC

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922