الوصف

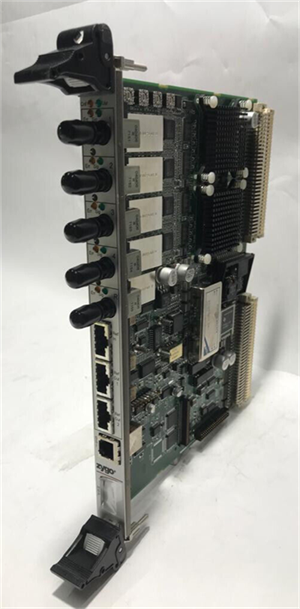

ZYGO ZMI-4004 DCS PLC Module

1. Product Name:

ZYGO ZMI-4004 DCS PLC Module

2. Product Description:

The ZYGO ZMI-4004 is a Distributed Control System (DCS) PLC Module designed to provide high-performance automation and process control in industrial environments. The ZMI-4004 module is an essential component of the ZYGO control systems, offering reliable operation for a wide range of industrial applications.

This module is tailored for use in systems requiring high-speed data processing, fault tolerance, modular I/O configuration, and flexible communication capabilities. It is optimized for industries such as chemical processing, energy production, water treatment, manufacturing, and pharmaceuticals, where precise control and robust diagnostics are critical for continuous operation and safety.

The ZYGO ZMI-4004 module provides real-time control, enhanced data diagnostics, and remote monitoring features, making it suitable for large-scale automation projects. It also supports redundant power supplies and network communication protocols that ensure high availability and reliable operation in complex industrial systems.

3. Product Parameters and Specifications:

Model Number:

- ZYGO ZMI-4004

Product Type:

- DCS PLC Control Module

Manufacturer:

- ZYGO Corporation

Control System Compatibility:

- Compatible with ZYGO’s DCS Control Systems.

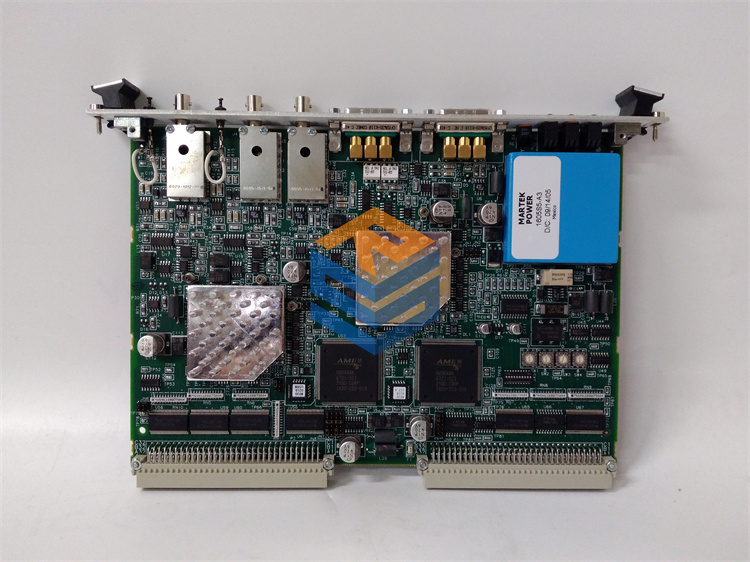

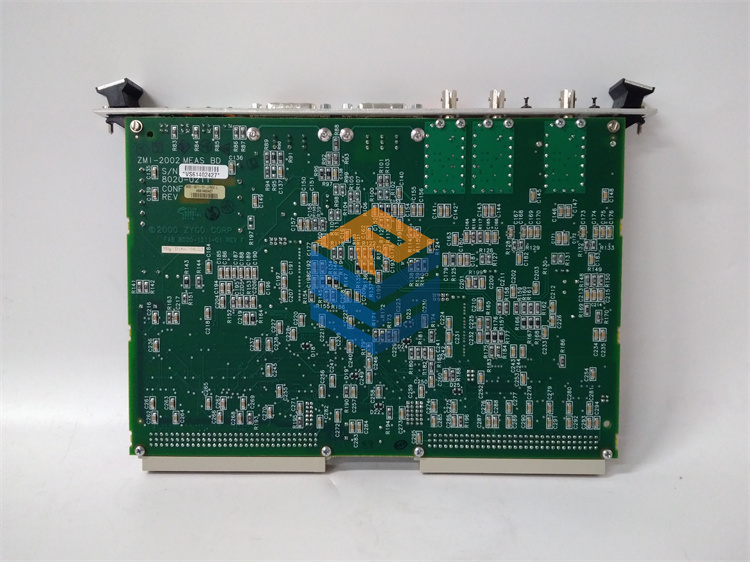

Physical and Mechanical Characteristics:

- Form Factor: Rack-mounted module for seamless integration into existing industrial control systems.

- Dimensions: Approx. 6.5 x 12.5 x 6.0 inches (may vary based on configuration).

- Weight: Typically around 2.5 to 4 kg, depending on the configuration.

- Mounting: Designed for easy rack mounting within standard industrial control panels or racks.

- Cooling: Utilizes passive cooling for efficient heat dissipation, ensuring reliable performance in demanding conditions.

- Power Supply: Operates on 24V DC for consistent operation.

- Rack Compatibility: Compatible with ZYGO DCS racks and PLC control platforms.

Operating Conditions:

- Operating Temperature: 0°C to 55°C (32°F to 131°F), suitable for most industrial environments.

- Storage Temperature: -20°C to 70°C.

- Relative Humidity: 5% to 95% (non-condensing).

- Vibration Resistance: Built to withstand typical industrial vibration.

- Shock Resistance: Can endure mechanical shocks during installation and operation.

Key Features:

- Modular I/O: The system allows for flexible I/O configurations, enabling users to tailor their setup for different application requirements.

- High-Speed Data Processing: Provides real-time control, ensuring rapid response for mission-critical processes.

- Redundant Power: Supports dual power supplies, ensuring continuous operation in case of a power failure.

- Advanced Diagnostics: Built-in diagnostic tools offer comprehensive health monitoring and fault detection for easier troubleshooting.

- Remote Monitoring and Control: Enables remote system monitoring and access via various communication protocols.

- Safety and Reliability: Designed to meet industry standards for safety, ensuring high availability and fault tolerance.

Communication and Protocols:

- Ethernet/IP: Standard communication protocol for high-speed, reliable communication across industrial networks.

- Modbus TCP: Facilitates communication with third-party devices and systems.

- Profibus: Supports Profibus for communication with field devices in complex industrial systems.

- HART Protocol: For communication with smart field instruments like transmitters and control valves.

- Redundant Communication: Dual network interfaces for ensuring network reliability and fault tolerance.

I/O Capabilities:

- Digital I/O: Supports a wide range of discrete inputs and outputs for sensors, actuators, and switches.

- Analog I/O: Handles continuous signals from devices like temperature sensors, flow meters, and pressure sensors.

- Modular Configuration: Users can select from various I/O modules, including input/output (I/O) modules for both digital and analog signals.

- Process Control I/O: Designed for accurate and reliable process control and monitoring.

4. Safety and Compliance:

- Safety Integrity Level (SIL): The ZMI-4004 is designed to meet SIL2 standards for safety-critical applications, ensuring robust operation in high-risk environments.

- Certifications: Compliant with key industry standards, such as UL, CE, and CSA, ensuring safety and performance.

- Environmental Compliance: Conforms to RoHS and WEEE regulations, ensuring environmental responsibility.

5. Applications:

The ZYGO ZMI-4004 DCS PLC Module is ideal for applications requiring high precision and reliability, such as:

-

Manufacturing:

- Automation of assembly lines, robotics control, and material handling.

- Production optimization and quality assurance for better throughput and reduced waste.

-

Energy Production:

- Power plant monitoring and control, grid distribution, and substation automation.

- Energy generation and renewable energy integration.

-

Chemical and Pharmaceutical Processing:

- Batch processing control, mixing and blending operations, and reactor monitoring.

- Regulatory compliance, quality control, and environmental monitoring.

-

Water Treatment:

- Water quality monitoring, wastewater management, and pump station automation.

- Remote diagnostics and SCADA systems integration.

-

Food & Beverage Processing:

- Production line control, supply chain management, and quality inspection.

- Recipe management and batch control for product consistency.

6. Conclusion:

The ZYGO ZMI-4004 DCS PLC Module offers an advanced, reliable, and flexible solution for industrial automation needs. With its high-performance processing, modular I/O capabilities, and robust safety features, it is ideal for applications where uptime and precision are critical. The module’s communication versatility, redundancy options, and diagnostic tools ensure long-term performance in diverse industrial environments, making it a valuable asset for manufacturing, energy, chemical, pharmaceutical, and water treatment industries.

ABB BC810K01 PLC DCS

3051C63A22A1BS0M515 PLC DCS

264PSGSSB1B1 V3L1B1C1

ABB 086318-501 PLC DCS

ABB 086406-502 PLC DCS

ABB 086444-005 PLC DCS

ABB MPRC086406-502 PLC DCS

ABB MPRC086318-501 PLC DCS

ABB MPRC086444-005 PLC DCS

ABB 3BUS208797-001 PLC DCS

ABB 3BUS208728-001 PLC DCS

ABB DSAI133A PLC DCS

ABB 3BSE018290R1 PLC DCS

ABB DSTA155 57120001-KD/1 PLC DCS

DSTA155 57120001-KD/1 PLC DCS

ABB 57120001-KD/1 PLC DCS

ABB DSTAOO1A PLC DCS

3BSE015195R1 PLC DCS

ABB DSTA0O1A PLC DCS

ABB DSTA022A PLC DCS

ABB 3BSE015196R1 PLC DCS

ABB DSTA022A PLC DCS

ABB DSTA156 57120001-KH PLC DCS

ABB 57120001-KH PLC DCS

ABB DSTA156 PLC DCS

ABB IP854 3BSE025349R1 PLC DCS

ABB 3BSE025349R1 PLC DCS

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922